Evaluating Oil Characteristics

When optimizing the performance of a styrenic block copolymer (SBC) pressure-sensitive adhesive (PSA), the focus often lies on the polymer and resin system, not on the oil that is used as a plasticizer. Since many adhesive formulations contain significant amounts of plasticizer, it can be valuable to evaluate the impact that different types of oil have on specific adhesive systems.

Mineral oil consists of a mixture of different hydrocarbon molecules with different chemical characteristics and, in addition to the molecular distribution, the oil can be more or less refined. All of these factors influence the performance of the oil in the adhesive.

Mineral oil that is used as an adhesive plasticizer originates from crude oil. Crude reserves can be found in a number of locations worldwide, and different crude sources result in different types of plasticizing oil, typically categorized as naphthenic or paraffinic. Depending on the molecular size distribution, the density of crude oil can be characterized from light (0.83 kg/dm3) to heavy (1.04 kg/dm3).

Crude Characteristics

A typical crude consists of carbon (84%), hydrogen (14%), sulfur (1-3%), nitrogen (< 1%), oxygen (< 1%), metals (< 1%) and salts (< 1%). The main part of the crude is represented by hydrocarbons, which can be present in different structures: paraffins (normal or straight hydrocarbon chain), isoparaffins (branched hydrocarbon chain), aromatics (unsaturated six- carbon rings), naphthenes (saturated ring structures), and olefins (unsaturated chains). Depending on the ratio of the different hydrocarbon structures, the crude can be categorized into paraffinic, intermediate or naphthenic, which often correlate to light, medium, and heavy crude types, respectively.The selection of crude oil is crucial in order to optimize the profit for a given refinery. The majority of refineries prefer light crude because they focus on the output of lighter molecules in order to serve the fuel industry. The technology has progressed to the point of enabling the cracking of the remaining bigger molecules, leaving a very low yield of the fraction available to be used as lubricating oil.

On the other end of the scale, a few specialized refineries focus on optimizing the yield of the lubricating oil fraction, and these refineries gain from using the heavy crude type. Naphthenic crude is usually classified as heavy and is therefore not suited for fuel production. These specialized refineries’ dedication to oil (vs. fuel production) makes possible a closer relationship between the oil producer and the adhesive industry, which means production can be steered to the needs of the market.

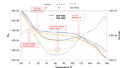

Figure 1. Viscoelastic Properties as a Function of Temperature. Note: 8mm top plate, 25mm bottom plate, 10 rad/s, 5°C/min. G' illustrates the material's ability to store energy. G" illustrates the material's ability to flow. Tan Delta is the ratio between G" and G'.

Refining

The first step in the refining process is to separate the crude oil into fractions; different hydrocarbons have progressively higher boiling points and can therefore be separated by distillation. The distillation process determines oil properties such as viscosity, boiling range, molecular weight distribution and volatility.The next step is to upgrade the distillates to oil products with secured quality and consistency; this is achieved through two different techniques based on either separation or conversion. In the separation process, an extraction technique is applied where the distillate is mixed with a polar solvent, like SO2 or furfural, which forms a separate phase. Heteroatom- and polyaromatic-containing molecules are partially dissolved in the solvent phase and can be removed. This process produces oil with relatively high aromatic and sulfuric contents.

Many of the units used in solvent refining are older and require upgrading, which, in many cases, is not economically justified. For this reason, solvent-refined products will probably be phased out of the market in the long run.

The distillate is hydrogenated in the conversion process, which chemically converts the unwanted molecules into those that are useful. In the hydrogenation process, polar, aromatic and hetero-aromatic compounds (along with added hydrogen) are adsorbed on a catalyst surface. The active surface of the catalyst is up to 200 m2/g of catalyst. Here, the molecules react with hydrogen. Under mild conditions, only heteroatoms react to form H2S, water and ammonia. By increasing the severity, the aromatic rings will become more and more saturated and, to some extent, opened.

Since the polyaromatics are the most reactive compounds, the major part of the remaining aromatic compounds in the oil will consist of non-carcinogenic monoaromatics. The H2S from the process is converted into pure sulfur in the sulfur recovery unit. Due to the recovery and conversion of sulfur (as opposed to its removal), the hydro-treatment process has a relatively low environmental impact. Depending on the conditions, this process can produce highly refined oils with very low aromatic and sulfur content.

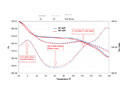

Figure 2. 180° Peel Adhesion, Probe Tack and SAFT

Evaluation

A study was conducted to evaluate the impact of different oils in an adhesive. Both the origin of the oil (crude) and the refining technique were taken into consideration. It is difficult to provide a full picture regarding how to predict the performance of a given oil in an adhesive, but the study offers some conclusions that could facilitate the adhesive formulation process.The study was performed on an adhesive system that was designed to be used as a packaging tape. In order to minimize the amount of variables, the formulation was as simple as possible and included only polymer, resin, oil, and antioxidants. The base polymer used was Kraton® D1160 E, a linear SIS triblock copolymer with bound styrene of 18.5% mass. The resin used was Piccotac 1094-E from Eastman, which is a low-molecular-weight aliphatic hydrocarbon resin. The formulation consisted of 44% base polymer, 46% resin, 9% plasticizing oil and 1% Irganox 1010 (antioxidant).

One objective was to compare two oils with equal refining degrees but different crude origins. Both oils are severely hydro-treated and classified as technical white oil (TWO). The tested adhesives included NAP-TWO, which is the adhesive prepared with naphthenic TWO, while PAR-TWO is the adhesive prepared with paraffinic TWO. The characteristics of the two oils are detailed in Table 1.

The following characteristics can be considered the main differences between naphthenic and paraffinic oil:

- Density: the higher ratio of ring structures in naphthenic oil results in higher density

- Viscosity index (VI): naphthenic oil’s VI is lower, which means that the viscosity decreases faster than paraffinic oil when temperature is increased

- Flash point: volatility is generally somewhat higher for naphthenic oil

- Pour point: naphthenic oil displays better low-temperature properties due to the lack of waxes

- Viscosity gravity constant (VGC): a measure of the solvent power of an oil; the higher the VGC, the better the solvent power. The VGC value is dependent on the hydrocarbon type distribution; a high aromatic content would give a high VGC but also a higher level of interaction with the hard styrene domains (crosslinking function in SBC). With the tested highly refined oils, the VGC is only dependent on the naphthenic and paraffinic distribution, so a higher content of naphthenic structures provides an oil with a better solubility profile.

Figure 3. Viscoelastic Properties of the Two Prepared Adhesives

Results

Dynamic mechanical analysis (DMA) was used in this study to evaluate changes in viscoelastic properties when using different types of oil in the same adhesive formulation. DMA gives nuanced information of the viscoelastic properties of a polymeric material, but tests like peel adhesion, probe tack and shear adhesion failure temperature (SAFT) were also used to better assess the adhesive performance (see Figure 1).As is evident, the Tg of the adhesive is lower with the PAR-TWO compared to the NAP-TWO. This is consistent with the Tg difference of the oils alone (10°C), but the difference in Tg is less (3.5°C) in the adhesive. This can be an effect of the different degree of interaction with the midblock of the two oils. Naphthenic oils have a closer solubility parameter (Hildebrand) to isoprene than paraffinic oils, which leads to improved miscibility.

Figure 4. 180° Peel Adhesion, Probe Tack and SAFT of the Two Prepared Adhesives

The third region shows how the type of oil affects the elastic modulus (the ability of the material to store energy). The adhesive prepared with NAP-TWO shows a higher modulus over the entire rubber plateau region, indicating a harder adhesive. This can be explained by the density difference between the two oils. The softening of a polymeric material is about creating free volume between the polymer chains. To obtain the same softening effect with NAP-TWO (0.893 kg/dm3) compared to PAR-TWO (0.874 kg/dm3), more naphthenic oil needs to be added. From an economic point of view, it is beneficial to use an oil that allows higher loadings, since the oil is a relatively inexpensive component in the overall formulation.

The loss modulus represents the adhesive’s ability to flow. In the adhesive melting region, the adhesive prepared with NAP-TWO shows higher ability to flow, which is in line with the lower VI of naphthenic oil. Lower melt viscosity could be positive from an application temperature point of view. However, it also suggests that adhesives prepared with naphthenic oil show somewhat lower heat resistance compared to paraffinics with higher VI.

In addition to DMA analysis, the peel adhesion, probe tack and SAFT were measured by Chemsultants International. All samples were conditioned at 23°C (± 1.5°C) and 50% relative humidity (± 5%) for 24 hours prior to testing, and all tests were replicated five times. The peel adhesion was evaluated by measuring the force required to peel the tape from stainless steel at a 180° angle (modified ASTM 3330). The probe tack tests were conducted on a ChemInstrument AR-1000 adhesion releaser tester (ASTM 2979). Shear adhesive failure temperatures were evaluated on a stainless steel substrate with 500 g weight and a temperature increase of 30°C/h (ASTM 4498).

Table 1. Characteristics of the Naphthenic and Paraffinic Technical White Oils

The SAFT, which measures the resistance to deformation in a shear mode at elevated temperatures, was somewhat better for the adhesive prepared with naphthenic oil. This contradicts the DMA prediction, which showed a higher loss modulus for the NAP-TWO adhesive at high temperature and thus a predicted lower heat resistance. However, the initial strong bond and better cohesive properties perhaps compensate for the higher tendency to flow at elevated temperatures.

Table 2. Characteristics of the Hydro-Treated and Solvent-Refined Naphthenic Oils

Additional Testing

In addition, the adhesives were prepared with two naphthenic oils, one severely hydro-treated (HT-NAP) and the other solvent-refined (SR-NAP), as shown in Table 2. The main differences between solvent-refined and hydro-treated oils are sulfur and aromatic content. The sulfur content does not have much impact on the viscoelastic behavior of an adhesive system, but it can have a negative effect on color stability since it indicates the presence of heterocyclic compounds. The aromatic content of plasticizing oils influences both the viscoelastic and the adhesion properties of an adhesive (see Figure 3).SR-NAP oil gives an adhesive with a slightly higher Tg compared to the HT oil. This can be explained either by the hydrocarbon distribution or the viscosity difference of the two oils. In theory, the higher amount of rigid aromatic structures in the SR-NAP oil should delay the transition. Since the aromatic difference is not as pronounced as the viscosity difference between the HT-NAP and SR-NAP oils, however, the Tg difference is most likely dependent on the oil viscosity.

The HT-NAP adhesive has a somewhat lower tan delta in the rubber plateau region, indicating better cohesive properties. This can be explained by the higher amount of aromatic structures in the SR-NAP oil. The aromatic molecules soften the hard styrene blocks that act as a crosslinking agent in the SBC, giving lower cohesive properties and thus the predicted lower shear resistance.

In the melt region, the differences are surprisingly small at only a 1°C difference for the crossover (tan delta = 1). The expected result of a higher aromatic content would be a faster decrease in viscosity (facilitate solvation of hard styrene domains combined with lower VI of oil), thus a shift of the “melting point” to a lower temperature. In this case, the higher viscosity of the SR oil, as well as the relatively small difference in aromatic content, probably compensates for this expected difference.

Taking into account the degree of uncertainty, the two oils show relatively similar peel adhesion properties, though the HT-NAP formulation reaches slightly higher values (see Figure 4). The HT-NAP also shows somewhat higher tack performance and slightly better heat resistance, which is consistent with the prediction from the DMA measurements.

Conclusion

The results from this study demonstrate the impact that different highly refined plasticizing oils have on SIS-based packaging adhesives, illustrating that it is possible to fine-tune adhesive properties through the choice of oil. The formulation studied here was designed for packaging tape that contains rather low concentration of plasticizing oil. Even if the oil load was only 9%, however, the effect of naphthenic/paraffinic character of the oil could clearly be seen. The differences were not as evident in the comparison between the two naphthenic oils of different refining technique/degree. This result indicates that, if the viscosity is sufficiently high, oils with slightly higher aromatic content can be used without a significant change in adhesive properties.Highly refined naphthenic oils combine a close midblock interaction with the enhancing phase compatibility of tri-block copolymers (SIS) without softening the styrene endblock. This gives a unique combination of excellent adhesion and wet-out properties, along with maintained or improved cohesive strength. In addition, the higher density of naphthenic oil might give rise to slightly lower free volume between the flexible isoprene chains, resulting in higher intermolecular forces and thus a stronger adhesive.

For more information, visit www.nynas.com.

Links

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!