Enhancing Assembly Line Efficiencies with Silicone Foams

Silicone foams offer greater flexibility and production efficiencies to boost assembly line productivity.

Figure 1. Robots used in the assembly line.

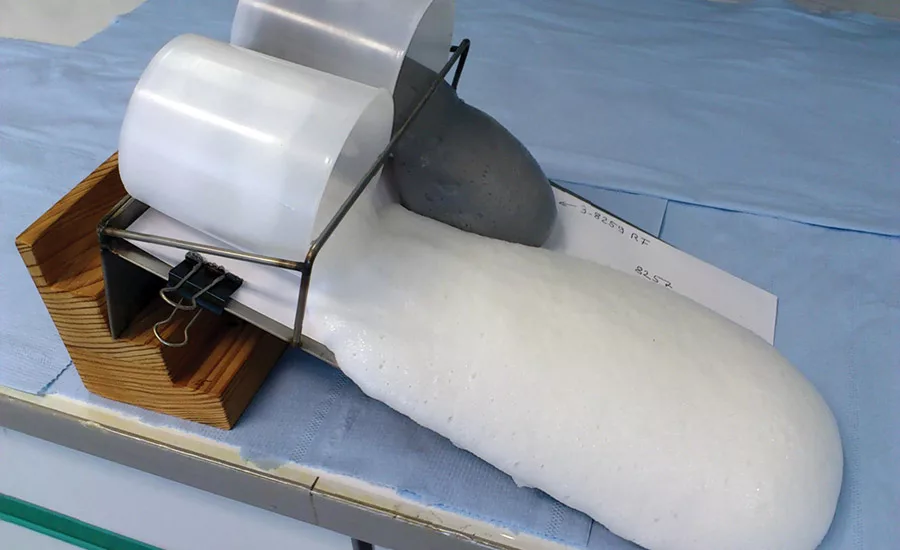

Figure 2. Processing silicone foams for form-in-place foam gasketing.

Figure 3. Difference between flowable and reduced flowable foams.

The global manufacturing industry has faced many challenges and has had to adapt to growing megatrends across the globe to remain competitive. Manufacturers have had to become more customer focused and flexible to keep up with consumers who are better informed about products on the market and expect new and improved products on demand. In addition, factory floors have also had to adapt to digitization by incorporating latest-technology systems and equipment, with an increasing uptake of robotics to complement factory workers on the assembly line. Adapting to these megatrends while optimizing production, logistics and distribution efficiencies is essential to ensuring that companies remain competitive.

As these changes are driving advances in manufacturing processes and technologies, they are also driving material improvements to ensure that final products are reliable and of high quality. Silicone foams for compression gaskets address customer needs for greater flexibility, production efficiencies and the increasing use of robotics on the assembly line (see Figure 1). Reformulated to meet current REACH standards, the foams are a hybrid technology, falling under room temperature vulcanization (RTV) solutions but using an addition cure mechanism that is typical for high-temperature vulcanization (HTV) products. The silicone foams are designed to be dispensed and cured directly on parts to form an integrated compression gasket.

Applications and Benefits

Two-part RTV silicone foams are ideal for forming a compression gasket or when an environmental seal is needed, which requires sealing against ambient air, splashed water, dust, or moisture. These foams can be applied in a variety of applications, such as in automotive parts, including seals for vibration and noise dampening; housing for electronic devices; exterior lighting; and domestic appliance components, including in gas boilers and ceramic hobs. Essentially, they can be used in almost any application where foamed tapes are used.

These silicone foams enable more efficient production for manufacturers by contributing to cost savings and reduced waste. Silicone foams require less materials when high tolerance gaps exist, compared to standard two-part sealing materials. What’s more, foams are light in weight, thus reducing the total weight of vehicles and helping to save on total cost of ownership in the long term.

Furthermore, these foams enable flexibility and reduced downtime by addressing manufacturers’ serviceability issues as they allow for fast and recurrent assembly and disassembly. Manufacturers can also rely on silicone foams for good UV, thermal and chemical resistance, thus contributing to the increased life time and reliability of parts. Due to the inherent beneficial properties of silicones, silicone foams help address customers’ current challenges on the assembly line while providing application versatility, durability, aesthetics and value.

Processing

In order to process these silicone foams, the two-part silicone RTV foam is mixed and directly dispensed onto the surface that needs to be sealed. The dispensed foam gasket expands in its liquid stage and cures to a foamed solid elastomer within 10 min at room temperature. This process provides a low modulus integrated compression seal with a fine-cell structure. It is important to note that silicone foams are not in fact adhesives.

The compression gasket can be handled after approximately 10 min; however, waiting 24 hrs to assemble is recommended, as the cure time has a high influence on the mechanical properties of the foam (e.g., the compression set). The longer the cure time, the more the compression set will improve, enabling the compression gasket to go back to its original shape when released from application stress.

Figure 2 shows how the two-part RTV silicone foams are processed in more detail. First, they are pumped in via two pressurized tanks, which make up the dispensing unit. They are then mixed in the mixing chamber and applied directly onto the part to be sealed. The robot follows the contour of the component and applies a precisely metered bead of silicone foam directly onto the sealing surface. Heating can be applied in the heating tunnels if a more efficient cure and a faster assembly are required. A dynamic mixer is suggested, as it will make the process more robust and flexible. It also allows for less waste during the production stops. In addition, it is important to note that the type and degree of mixing and shear can significantly affect the cell structure, cure, and density of the final foam product.

Curing

When parts A and B are mixed, silicone foams crosslink from a polyaddition reaction, and hydrogen gas is released from a polycondensation reaction to promote cell formation. Silicone foam materials contain Pt-catalysts, which help create the three-dimensional network elastomer of the final foam, with a typical foam expansion ratio of 1:2.5-1:4. The system is sensitive to temperature and mixing quality; therefore, proper mixing of the components is required to ensure a homogeneous cell size distribution for a reliable foam. Further adding to efficiencies and costs, these silicone foams do not require external blowing agents due to the nature of their chemistry.

Certain chemicals can inhibit curing, causing an incomplete cure or sticky product. Amines and sulphur-containing materials are strong inhibitors, as are organotin salts such as those used in condensation-cure silicones. To avoid inhibitor contamination of A and B liquid components, dispensing tubes and seals used in meter/mix equipment must be made of PTFE rather than conventional plastic or rubber materials.

Compression

Ensuring a gasket can recover to its original shape after being compressed for long periods of time is particularly important. As gaskets are exposed to continuous compression or repeated cycles of compression and release, a gasket with a low compression set is ideal. When testing these silicone foam products for

22 hours at 70°C at 50% compression, they display low compression sets retained at high service temperatures. Furthermore, these tests also demonstrate that these silicone foams maintain their resiliency over a broad temperature range and resist taking a permanent compression set. ASI

For more information, visit www.dowcorning.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!