Pressure-Sensitive Adhesive Characteristics and their Impact on Foam Anchorage

Understanding the variables involved in PSAs can lead to first-time-right decisions on adhesive selection and processing.

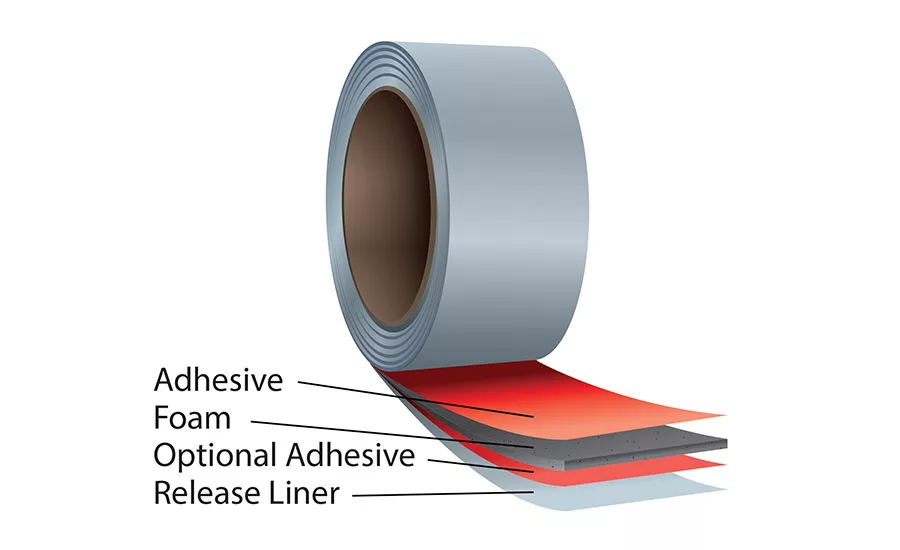

Foam tapes are used in a wide range of markets, such as automotive, packaging, electronics and medical. They serve a number of functions—from vibration dampening to shock absorption to temperature insulation. The end-use application and function of the tape generally guides the overall construction, including the foam and adhesive(s) selected. In general, foam tapes can be either single- or double-coated constructions. In the case of a single-coated tape, the same adhesive must bond to the foam and to the substrate. In double-coated tapes, two different adhesives can be chosen to enhance the anchorage to both the foam and the substrate. Figure 1 depicts the layers of a typical foam tape.

Crosslinked polyethylene, polyurethane (polyether and polyester), ethylene propylene diene monomer (EPDM), and nitrile-based materials are some of the common foam types used in tape applications. Foam characteristics such as chemistry, surface texture and energy, cellular structure, and density impact adhesive choice. Identifying the optimal adhesive(s) is no easy task, and there is no one-size-fits-all solution that satisfies the needs for all markets, functions, and foam types. A customized approach for each application is required to ensure that the adhesive sufficiently anchors to the foam and meets all critical-to-quality (CTQ) requirements, such as resistance to temperature, UV, and/or solvents.

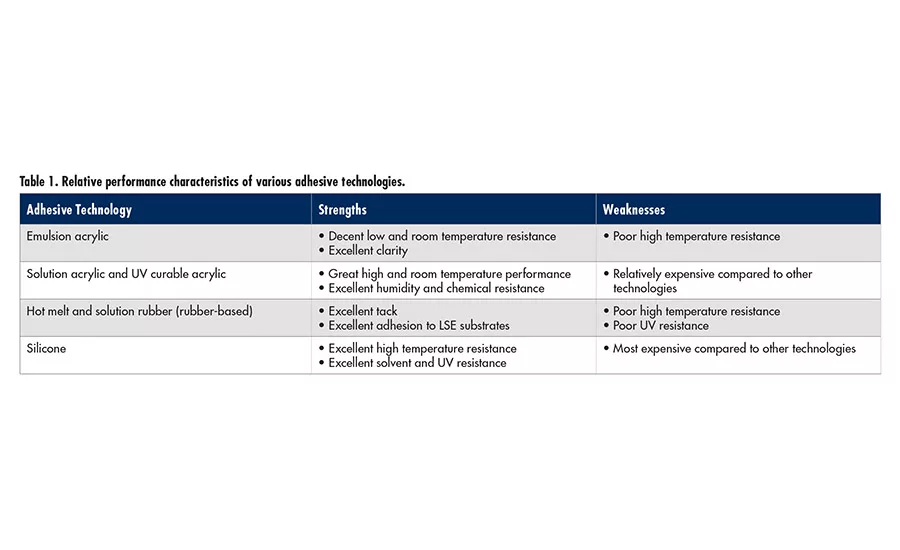

A variety of pressure-sensitive adhesive (PSA) technologies are available, all of which have their strengths and weaknesses in addressing these CTQ requirements. Table 1 highlights general performance attributes of four main adhesive technologies.

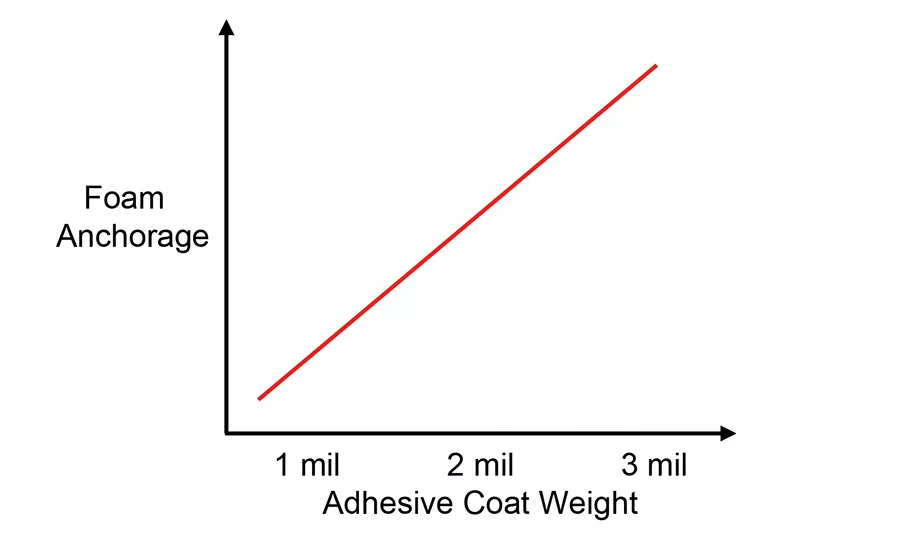

While ensuring that the chosen adhesive bonds to the substrate (wood, plastic, metal, etc.) and meets all CTQ requirements (UV resistance, chemical resistance, etc.) is important, finding an adhesive to sufficiently anchor to the foam is a significant challenge. During the adhesive coating process, widely known and commonly used processing levers can be adjusted to improve adhesive anchorage on foams. First, the surface energy of the foam should be evaluated and can be modified via corona treatment if a higher surface energy is required. In addition, the adhesive coat weight should be optimized. In many cases, increasing the adhesive coat weight can improve the anchorage of the adhesive to the foam (see Figure 2). If transfer coating, using a heated or pressurized nip to laminate the adhesive to the foam can also improve anchorage. Finally, the coating method must be evaluated. While transfer coating is most common when working with foams, direct coating of the adhesive onto the foam allows for some adhesive to flow into the foam surface, improving anchorage.

Though trial-and-error screening methods for foam anchorage can lead to a solution, a thorough understanding of foam-adhesive compatibility helps to accelerate speed to market for customers. With some insight into adhesive chemistry and formulations, the properties that impact adhesion to foams can be understood. Examples of these include: monomer selection and ratios, polymer molecular weight (MW), glass transition temperature (Tg), and softening point. Adhesive properties can be further modified with formulation ingredients such as crosslinkers, tackifiers and plasticizers. Several of these aspects are discussed in the subsequent case studies.

Monomers and Molecular Weight of Acrylic-Based PSAs

For acrylic-based adhesives, the ratio of soft and hard monomers is the first step in obtaining targeted PSA performance properties. Functional monomers provide crosslinking sites and can promote specific adhesion to certain substrates. A general ratio of roughly 70-90% soft monomers, 10-30% hard monomers, and 3-6% functional monomers is common. This determines the polymer Tg, which is the transition of the polymer from a glassy (hard, brittle) to rubbery (soft, elastic) state. The typical Tg range for PSAs is -60°C to -5°C, with PSAs generally applied and used above their Tg (i.e., in the rubbery, elastic phase).

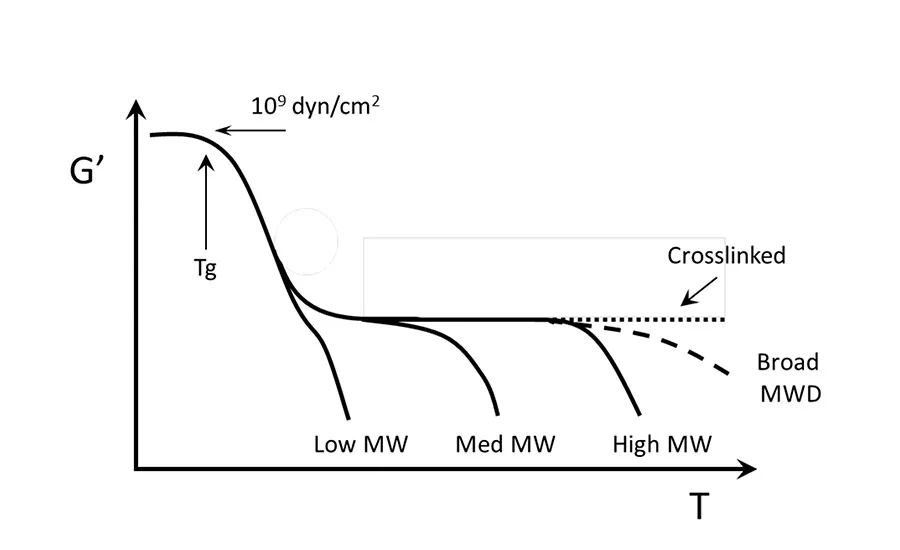

Rheology is used to study the viscoelastic behavior of adhesives and is a tool for determining Tg. Figure 3 shows a simplified rheology curve of the storage modulus, G’, compared to temperature for acrylic PSAs. In general, a broad molecular weight distribution (MWD) is desired to obtain a balance of adhesive (peel, tack) and cohesive (shear) strength of the PSA. However, in the case of anchorage to foams, low-molecular-weight adhesives provide better flow and wetting into the foam surface. Molecular weight is determined via the polymerization process and is guided by three main aspects: the monomer addition rate, the initiator addition rate, and the reaction temperature. To achieve a lower molecular weight, the monomer addition rate can be decreased, the initiator addition rate can be increased, and/or the reaction temperature can be increased. These relationships are critical to the polymerization process and the final MW of the polymer. With an understanding of the rheology of acrylic-based adhesives, customers can knowledgably select a product with the various attributes that are required for the end-use application (e.g., low MW for wetting and/or low Tg for low temperature applications). It must be noted that higher MW polymers can be formulated with tackifiers and plasticizers to improve the flow and wet out of the adhesive, making them a worthy consideration for foam tape applications depending on the desired end use.

Softening Point in Hot-Melt PSAs

In hot melt adhesives, the polymer is often comprised of styrenic block copolymers, such as poly(styrene-isoprene-styrene) (SIS) and poly(styrene-butadiene-styrene) (SBS) rubber. These polymers are formed via anionic polymerization, which provides a very narrow molecular weight distribution. Micro-phase separation of the midblock (i.e., isoprene or butadiene) and endblock (i.e., styrene) form physical crosslinks. These crosslinked polymers provide the inner strength, flexibility, and toughness that is critical to the adhesive. Contrary to the amorphous polymers in acrylic-based systems, crystalline rubber-based adhesives pass through a melt transition and are defined by their softening point. Factors affecting the softening point in hot melt PSAs include: polymer amount, polymer type (i.e., styrene content), and polymer MW. Tackifier choice and amount also affects the softening point; however, this will be discussed separately in the next case study.

To better understand the relationship of softening point and the ability of the adhesive to wet into a foam, the foam anchorage performance of four adhesives with varying softening points was compared. Hot melt formulations varying in softening point from 155°F to 253°F were tested on polyurethane polyether and EPDM foams using a simple hand peel test. To ensure that the wet out of the adhesive into the foam could only be attributed to the softening point, no additional promotion of anchorage via heat and/or pressure was used. Sample strips of 2 mil adhesive laminated to 2 mil PET were adhered to the foam and allowed to dwell at room temperature for 20 min. The graph in Figure 4 shows the results, with a rating of “0” being no foam tear and a rating of “4” being complete foam tear. As shown by the results of the testing, lower softening point adhesives tend to more sufficiently anchor to various foam types. However, higher softening point adhesives can still be utilized in foam tape applications. Generally, with the promotion of anchorage via a heated or pressurized nip, many adhesives can sufficiently wet into the foam substrate.

Tackifiers in PSAs

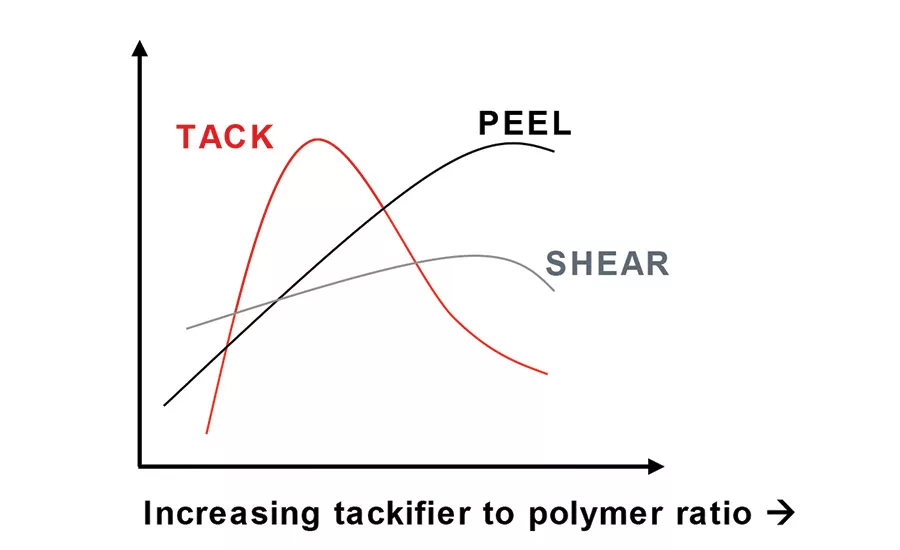

Tackifiers are used to balance the adhesive and cohesive properties of PSAs by increasing peel and tack. Tackifiers are low molecular weight, amorphous polymers; therefore, they tend to raise the Tg of the adhesive and soften the polymer by lowering the modulus. Acrylic-based adhesives may or may not contain tackifier depending on the desired properties, while tackifiers in rubber-based hot melt adhesives are a critical formulation component. The increased tack of the adhesive combined with the softer polymer improves the ability of the adhesive to anchor into the foam substrate.

Tackifiers are derived from two main sources: petroleum-based hydrocarbon resins and naturally sourced resins. Naturally sourced resins are used more prominently in PSAs. These resins are available in a range of softening points for formulation latitude. When formulating, there is a point where the addition of too much tackifying resin reduces or eliminates tack performance. The balance of adhesive (peel, tack) and cohesive (shear) properties is heavily influenced by the tackifier amount, as shown in Figure 5.

Conclusion

Depending on the desired performance properties and targeted end-use application, a variety of PSAs are available for foam tape applications. With regards to the adhesive, polymer and formulation choices can be targeted to meet the needs for the specific foam type. In addition to adhesive modifications, changes to the foam itself and/or the coating process can also be implemented to improve the adhesive’s anchorage to the foam substrate. Understanding these variables can lead to first-time-right decisions on adhesive selection and processing in order to meet the needs for any foam tape application. ASI

For more information, visit www.pressure-sensitive-solutions.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!