Strategic Solutions

Silane-Modified Polymers Find Yet Another Application

Installation of large-format tile offers new opportunities for adhesive formulations.

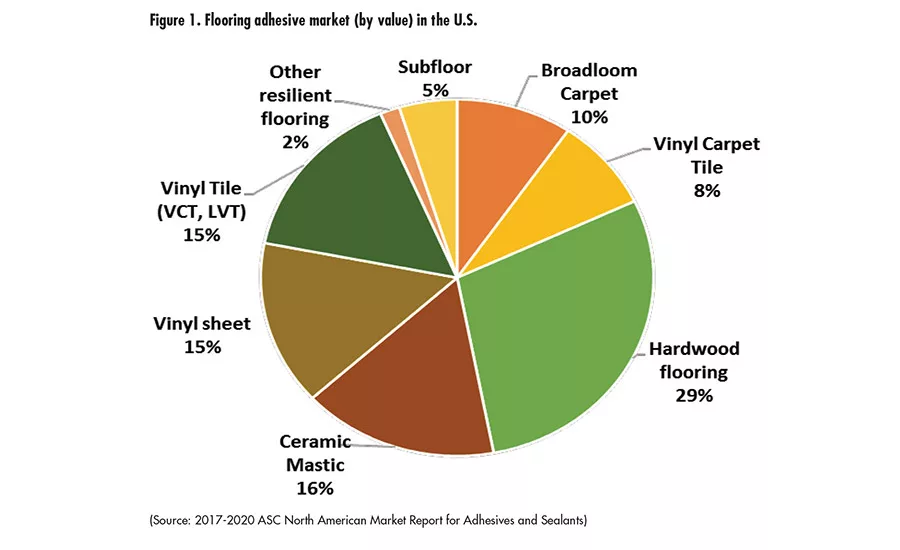

Figure 1. Flooring adhesive market (by value) in the U.S.

Super-format tile is much larger in size (up to 3.5 x 9 m) and relatively thin (3-5 mm).

This common installation method is used to ensure no sag or unwanted tile movement.

In 2017, the U.S. ceramic tile market for flooring and wall installations was valued at $3.6 billion, representing 14.2% of the flooring market value with a growth year-over-year of 6.8%, according to Floor Covering Weekly (7/23/2018). The two primary types of products used for installation are cementitious (and often polymer-modified) “thin-set” mortars and water-based adhesives, typically referred to as mastic materials. The difference is that the cementitious materials require mixing with and activation by water prior to use; the mastic products are ready to use, requiring only stirring prior to application with an appropriately sized notched trowel.

Floor Adhesive Use

Although cementitious installation materials represent the majority of product used, ChemQuest estimates the value of ready-to-use ceramic mastic products in the U.S. to be $120 million, accounting for approximately 16% of the total flooring adhesive market value (see Figure 1). In many cases, these types of products offer ease of use, particularly to the residential DIY/BIY user, normally with smaller format (12 x 12 in. or less), porous tile installed on porous substrates, such as plywood subfloors or porous concrete.

For the past 10-15 years, the ceramic and porcelain tile markets have experienced tremendous market growth for larger format tile. These products are subdivided into three categories; The Tile Council of North America (TCNA) defines large, heavy tile as at least 15 in. on one side with a density of 5 lbs/sq ft, while gauged porcelain tile are < 1 sq m, and gauged porcelain tile panels are > 1 sq m.

“Super-format tiles,” as the name implies, are much larger in size (up to 3.5 x 9 m) and relatively thin (3-5 mm). As is typical of dominant design trends in ceramic and porcelain tile, stylistic and otherwise, many of these products were introduced in and are imported from Europe. These products have specific installation requirements due to their heavy weight. First, the installation must be on a floor or a wall, generally with a cementitious mortar and a ½ x ½-in. trowel with no slippage on a horizontal surface and no sag on a vertical surface. Coverage is exceptionally critical, requiring no voids under or behind the tile.

Installation

For floor installations, regardless of the specified bonding product, the surface needs to be extremely level to avoid excess stress on the large bonded tile. This requirement may necessitate the use of a high-quality self-leveling underlayment cement prior to tile installation.

Additionally, the bonding material requires certain environmental conditions to allow it to “dry” (not a full cure) between two dense and either non-porous or barely porous surfaces. The reason is two-fold: to develop optimum strength, and to minimize the threat of mold and mildew. The drying concern is made more challenging by another trend of incorporating thinner grout joints that allow less surface area for the water to evaporate from the drying mortar. “Self-drying” technology in the mortar is available to address these concerns.

Finally, a sufficient open or working time of 20-30 min is necessary for large-format and super-format tile on the floor and roughly 40 min for wall installations (to allow for repositioning of tiles or panels). Given that the thin, heavy tile or panels closely resemble (and are even cut similarly to) large panes of glass, the design of tile installation equipment is like window installation equipment, such as dollies equipped with adjustable height suction cups to move the panels into place.

For these and other reasons, the trend toward larger and less porous tiles is displacing water-based mastics. Relatively new to the market are moisture-cure bonding products, based on silyl-modified polymers, that provide trowelable consistency and sag resistance. The claim is these materials can set the largest format thin porcelain tile―in

some cases as large as ¼ in. x 5 ft x 10 ft

(6 mm x 1.5 m x 3 m) on walls and countertops.

Silyl (often referred to as silane-modified) polymers come in multiple types and have been used as the basis for numerous flooring installation products in recent years, especially for wood flooring. They offer a unique combination of adhesion performance and, in some cases, sound-dampening features. The growing porcelain tile market has provided yet another growth opportunity for these materials. ASI

Terry Potter, Ph.D., is a director at The ChemQuest Group. For more information, visit www.chemquest.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!