Pipeline Transmitters and Production Timelines: Meeting the Demands of Two Harsh Environments

The right adhesive allowed a pipeline manufacturer to ramp up and increase volume.

Figure 1. Comparison of bonded and unbonded halves of a display. Display bonding reduces solar reflections by two-thirds.

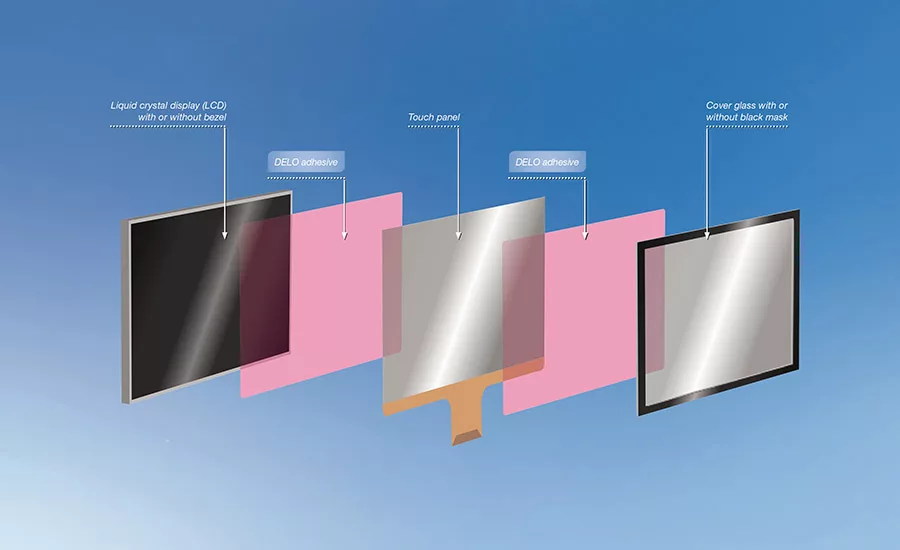

Figure 2. Illustration of adhesive layers in a display.

Figure 3. The 9900 transmitter for pipe systems from Georg Fischer has a particularly large display.

(Image courtesy of Georg Fischer)

Many industrial pipelines are exposed to the elements and must face tough environmental conditions, including humidity, and temperature and climate variations―often including heavy frost in the winter and long hot spells in the summer. The electronic equipment used in conjunction with these pipelines must also face these same demanding environments.

Georg Fischer offers pipes and system solutions for the safe transport of liquids and gases, lightweight casting components in vehicles, and high-precision manufacturing. The company manufactures a product for its control systems range that has an extremely large display, the Signet 9900 transmitter. This unit is used to measure and monitor fluid and gas media through a single-channel interface for sensors like flow, pH/ORP, conductivity/resistance, pressure, temperature, filling level, and salinity. It can be integrated into a control cabinet or installed in the field for use in a variety of applications, including media filtration, wastewater treatment, and chemical production. Due to the transmitter’s dimensions of 99 x 99 mm, information can be read at up to four or five times the distance of conventional transmitters, reducing the risk of incorrect readings or misinterpretation of the displayed values.

Display Bonding Improves Readability

Good readability is not just the result of a large backlit display; bonding the display also helps. In this process, a glass cover is bonded flat onto an LCD module using an optically clear adhesive. The refractive index of the adhesive is adapted so that light reflections can be reduced by up to two-thirds. At the same time, the shock resistance of the display increases because it is more stable in the event of shocks and falls.

In industries where fluid and gas pipes are used, electronic equipment has to be extremely resistant to adverse conditions. Georg Fischer researched different display adhesives for this robust transmitter that not only had to meet all of the optical requirements and harsh environmental factors, but also needed to promote an efficient production process. Because tape for display bonding provides inadequate humidity resistance, company representatives knew they needed to bond the display differently.

Initially, a two-component adhesive was chosen that theoretically met the optical requirements. However, air bubbles frequently form with two-component adhesives, even if both components are mixed accurately. This presents a problem, because bubbles are time-consuming to remove and may even result in a unit being scrapped if they cannot be eliminated.

The pipe system provider also felt that the production process would be slowed down by using this type of adhesive. The complete bonding process, beginning with mixing and ending with excessively high storage costs in relation to the transmitter quantities required, was not going to meet their expectations for timely production.

Light Curing Accelerates the Process

After studying the situation and researching different types of adhesives, Georg Fischer reached out to DELO Industrial Adhesives, which suggested using a one-component, optically clear adhesive.* One-component, optically clear adhesives can be dispensed without bubbles and cure in a matter of seconds under high-intensity LED light. They can also cure in shadowed areas, where light cannot reach, through contact with humidity present in the air. This ensures that no fluid adhesive remains. Curing with light and humidity also enables displays to be handled immediately, further decreasing the production process time.

Testing and Results

Georg Fischer and the manufacturer subjected the bonded sample to three demanding industry-standard tests to ensure that the adhesive met the specified properties, even under the high demands of field use: an ultraviolet (UV) test according to ASTM G154; a simulation of outdoor weather conditions according to ISO 4892-2; and heat and humidity cycling from -15°C through 70°C. The adhesive met the optical requirements in all tests. The b value remained at an acceptable level for the degree of yellowness, meaning that Georg Fischer could be sure that the adhesive would not become perceptibly yellow, an obstacle that could obscure the transmitter display screen and not allow for a clear reading.

“It was the extensive reports and research conducted by DELO that instilled confidence in this new option,” says Gert Burkhardt, vice president of operations at Georg Fischer.

But for the adhesive manufacturer, the project did not end there. “In line with our company philosophy, an adhesive manufacturer should do more than just recommend an adhesive, provide samples, and then send an invoice,” says Robert Saller, managing director at DELO. “As well as conducting joint tests, effective project management should also include working with the customer to define the production process and all its curing parameters, and offering advice on choosing the right equipment all around.”

Georg Fischer opted for an area lamp for curing.** This LED lamp has a wavelength of 400 nm and cures the material at a low intensity within 60 sec. However, the valve of another manufacturer was better-suited for dispensing the adhesive, so its use was also recommended.

With the definition of the process completed, Georg Fischer has been able to forge ahead with the ramp-up phase, integrate the new adhesive into ongoing production, and increase the volumes of units.

For more information, visit www.delo-adhesives.com.

Editor’s note: Images are courtesy of DELO, unless otherwise noted.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!