Using Blue Light Absorbers to See Optical Adhesives Clearly

Blue light absorbers help an optical clear adhesive block light transmittance.

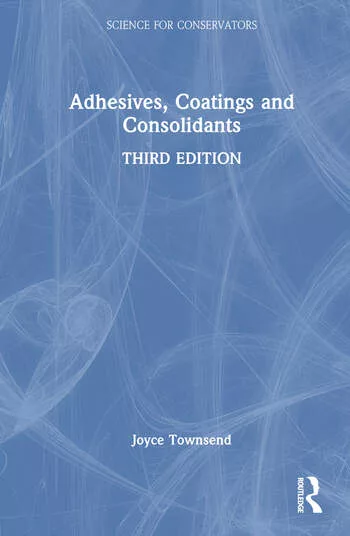

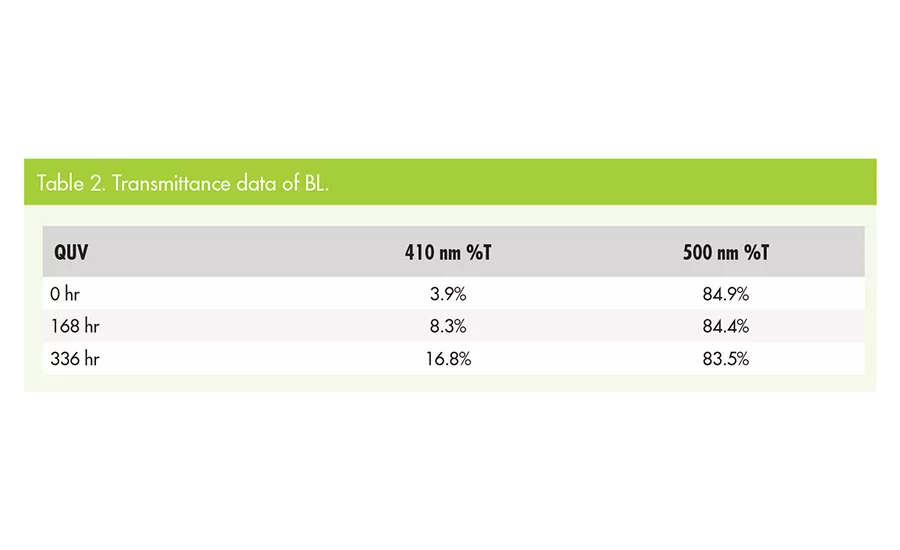

Figure 1. UV-vis spectra of BL.

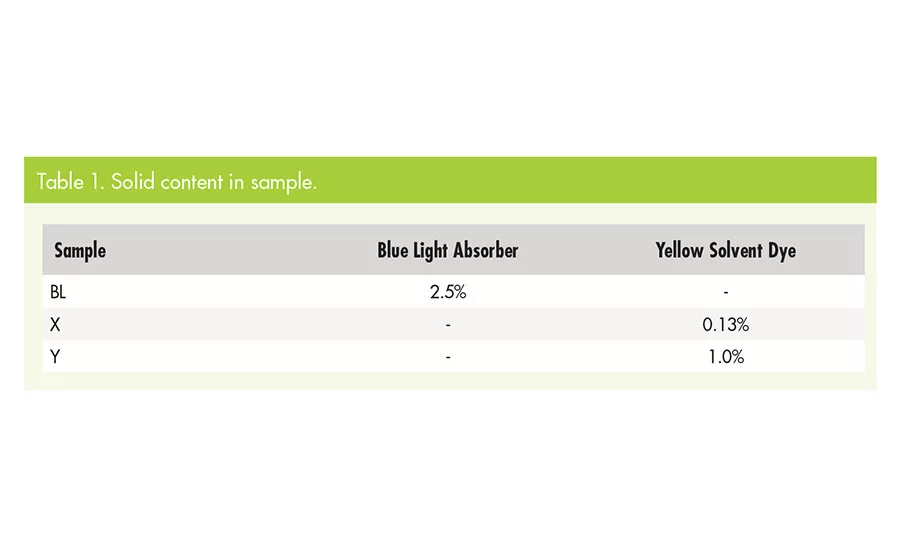

Figure 2. UV-vis spectra of X and Y.

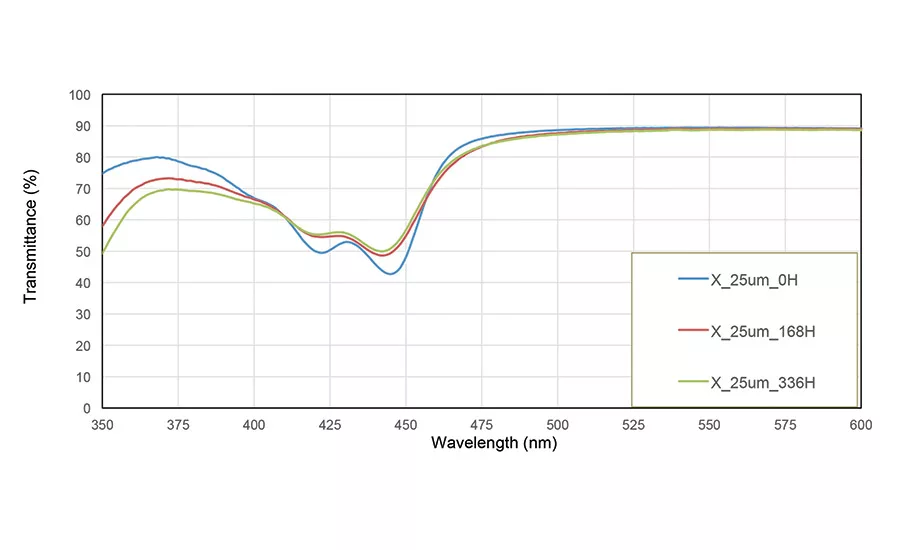

Figure 3. UV-vis spectra of X.

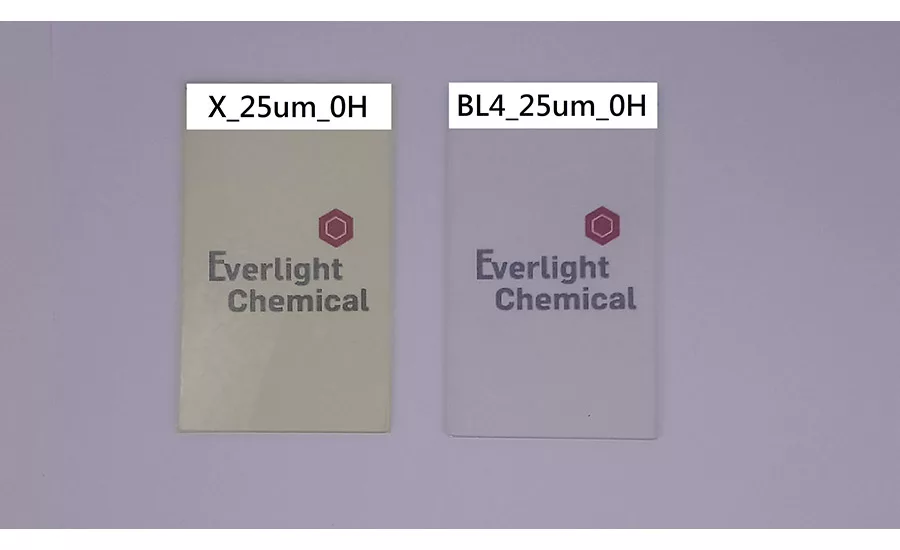

Figure 4. Appearance of X and BL.

Digital personal devices such as smartphones and tablets have become necessities in modern life. However, for image sharpness, most digital devices emit blue light of 380-500 nm in the light spectrum, with higher energy.1 In some studies, macular degradation has been shown to result from long-term exposure to these wavelengths.2,3

In daily life, blue light cut off is needed for health reasons in many situations. For instance, yellow dye is often introduced in eye glasses, goggles, liquid crystal displays (LCDs) and light emitting diodes (LEDs).4,5 These additives can be incorporated in optical adhesives for the same purpose. Therefore, optical adhesives are also widely used in the electro-optical, green energy and consumer markets. The adhesives can be found in acrylic, unsaturated polyester, polyurethane, and other resin systems. This article compares a blue light absorber and a yellow solvent dye in optical adhesive applications.

Experiment

Materials

HT-6678(TAPI) is selected for this optical clear adhesive system, which is a thermal curing solvent-based acrylic resin. In this study, the objective is to compare blue light absorber* with the indene solvent dye.

Method

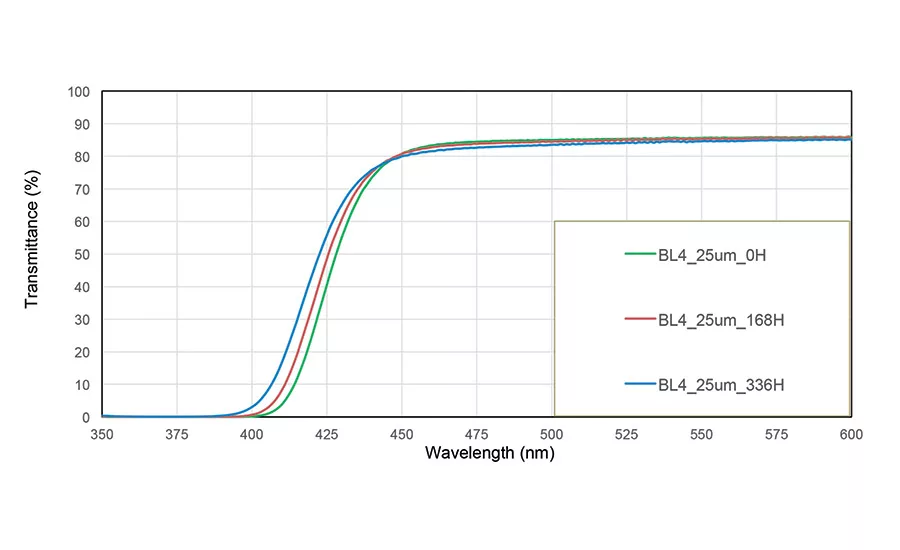

Optical adhesive was applied on a transparent release film with an automatic film applicator (ZEHNTNER, ZAA2300). The solids content of each sample is shown in Table 1. Samples were then put into the oven for solvent removal. After baking, laminate was applied to the glass with a laminator (HK, 330DS). The samples were finished in a glass/optical adhesive/release film structure.

Examination

To measure the transmittance spectrum of UV-vis (Shimadzu, UV-2600), cut-off ability was observed at specific wavelengths. The stronger the cut-off, the lower the transmittance value.

The CIE LAB color space (also known as CIE L*a*b*) is defined by the CIE institution (International Commission on Illumination). Color space components are distinguished in three numerical values, L* for the lightness, and a* and b* for the green-red and blue-yellow color components. UV-vis was used to measure this data. In addition, a QUV accelerated weathering (Q-LAB, QUV/se) test was conducted, in which the variation of UV-vis spectra was observed.

Results

Transmittance

The transmittance of BL is shown in Figure 1 and Table 2. BL, a 25 µm optically clear adhesive, manages to block the light transmittance at 410 nm, allowing less than 5% to penetrate. The transmittance at 500 nm of the sample remains quite high.

According to Figure 2, we can observe that X, a 25 µm optically clear adhesive, has high transmittance at 500 nm. However, it can only block partial blue light. Therefore, enhancing the solid content to 1.0%, Y has low transmittance at visible light, because of the opacity present. Therefore, yellow solvent dye has its limitation on the solid concentration for anti-blue light application.

Accelerated Weathering Test

After the QUV accelerated weathering test, the variation of UV-vis spectra was observed. X transmittance at 410-460 nm gets higher and higher as QUV time goes on, as shown in Figure 3 (p. 14). This is a result of dye degradation by irradiation. If the polymer contains impurities that absorb light, it becomes sensitive to UV light. Therefore, transmittance has dropped off at the UV region. In comparison, BL has slightly degraded at the 380-440 nm region through irradiation, and the transmittance result at 500 nm remains quite high.

Color

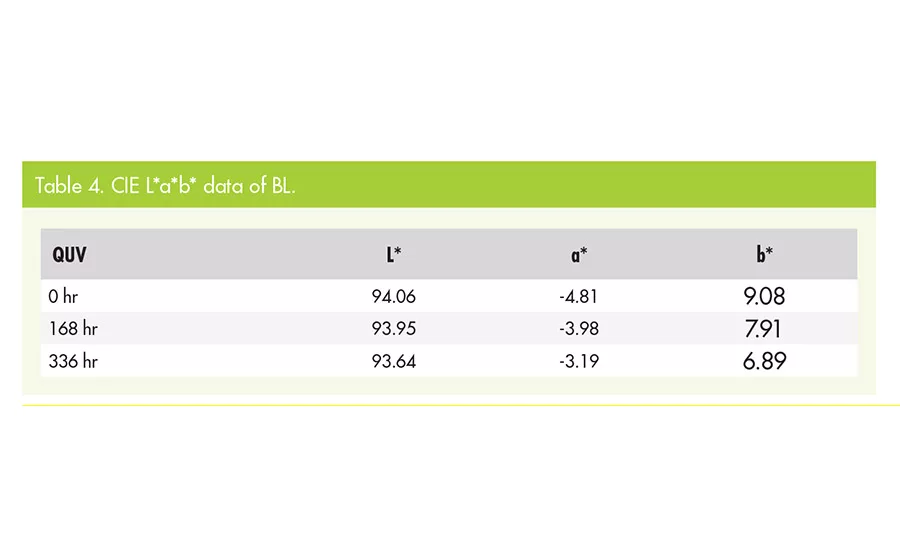

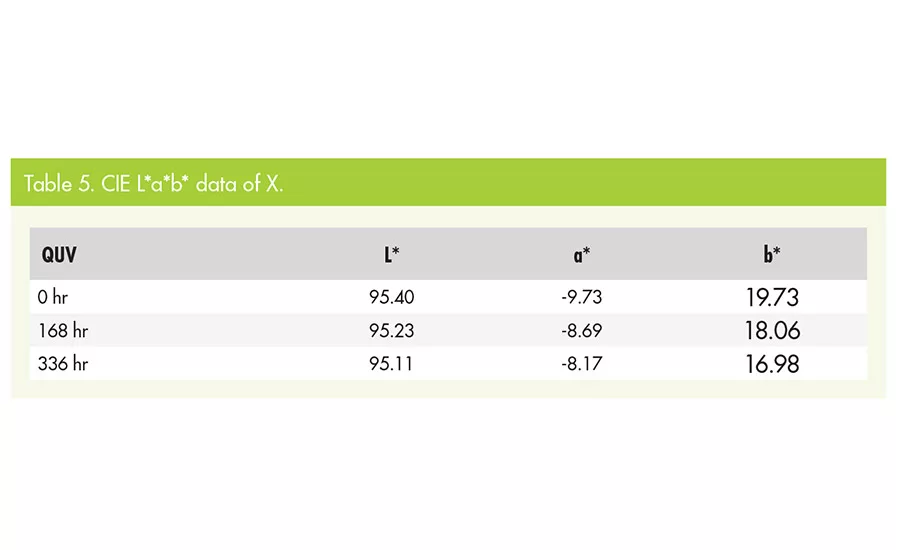

If the b* color is deep yellow, it will affect human sight. BL, a 25 µm optically clear adhesive, showed b* with 9.08 (see Table 4). Relatively, X showed b* with 19.73, getting lower and lower as the QUV accelerated weathering test time went on (see Table 5, p. 16). Therefore, BL weatherability is better than yellow solvent dye, and it does not affect visual changes.

Conclusion

In summary, yellow solvent dye has showed its limitations on many dimensions. Yellow solvent dye is sensitive to UV lights, which shortens its durability, and is not able to increase product concentration to boost blue light cutoff performance in optical applications after certain point. On the other hand, with the usage of 2.5% blue light absorbers, a 25 µm optically clear adhesive manages to block the light transmittance at 410 nm, allowing less than 5% to penetrate. Meanwhile, the transmittance at 500 nm of the sample remains quite high. The blue light absorber is more efficient in preventing blue light damage without compromising the visible light transmittance.

For more information, visit https://everlight-uva.com.

References

- International Organization for Standardization, ISO-13666.

- J. Wu, S. Seregard, B. Spimgberg, M. Oskarsson, E. Chen, “Blue Light Induced Apoptosis in Rat Retina,” Eye, 577-583, vol.13, 1999.

- Kirk Smick, OD, FAAO, “Blue Light Hazard: New Knowledge, New Approaches to Maintaining Ocular Health,” Essilor, 2013.

- Alcon Laboratories Inc., U.S. patent 5470932A, “Polymerizable Yellow Dyes and Their Use in Ophthalmic Lenses,” 1995.

- Feng Chia University, U.S. patent 2017/0227680 A1, “Hydrogel-Based Contact Lens and Methods of Manufacturing Thereof,” 2017.

- Sylvia Hung, Miles Hsieh, M.L. Wang, Y.H. Huang, Johnson Chen, M. H. Yen, “High Performance Blue Light Absorbers for Optical Clear Adhesive,” Industrial Material, 161-164, vol.330, 2014.

- Mitsui Chemicals, JP5620033, “Optical Material, Composition for Use Therein, and Use Thereof,” 2014.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!