Process Improvements

Enclosed System for Mixing and Production of Adhesives and Sealants

A new mixing and filling system allows for complete product manufacture, from mixing through to the filling stage, inclusive of the storage and filling of sealant and adhesive products.

When the tank is swung open, the unit is fully accessible.

The mixing blade (left) is retracted into the tank top (right) to enable the product to be pressed out of the mixer. (The video below illustrates this process.)

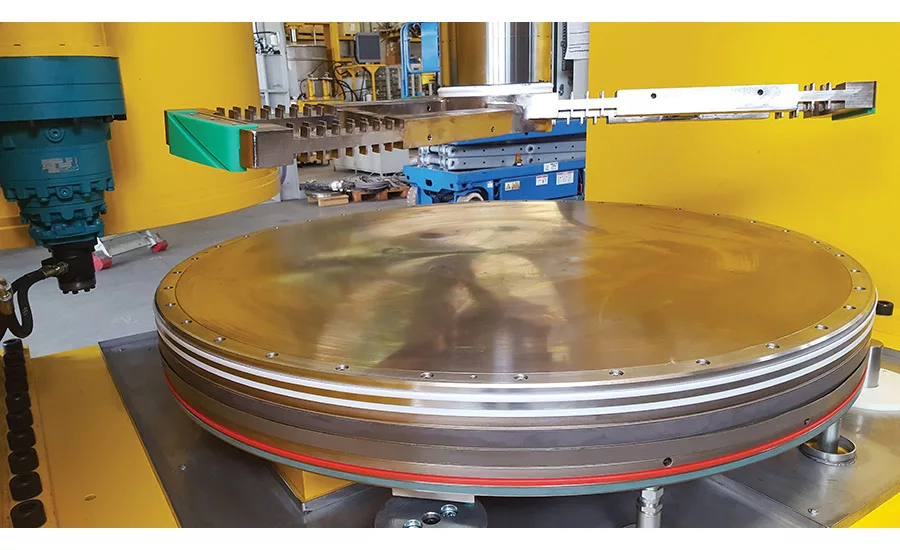

The press plate’s seal/cleaning system enables the seal and mixer vessel walls to be cleaned during the extrusion phase of the manufacturing cycle.

An enclosed and automated sealant/adhesive mixing and filling system has been launched that uses at its core the TPM Press Mixer. Designed and produced by Turello, this enclosed system is geared toward producing consistently high-quality products with short mixing times while reducing the risk of exposing moisture-cure or environmentally sensitive products to the atmosphere during the manufacturing and filling cycle.

The proprietary design allows for complete product manufacture, from mixing through to the filling stage, inclusive of the storage and filling of sealant and adhesive products. Total automation is possible with this process method, as is the reduction of employee exposure to potential environmental hazards.

Principle of Enclosed Process Operation

When used with associated equipment, the TPM Press Mixer forms the key part of a totally enclosed, fully automated sealant/adhesive manufacturing system. Production batches can range from 600-3,500 l. The process may start with the evacuation of all lines and vessels, as well as flushing or purging with inert gas. Process pressure ranges of -1,000 mbar vacuum to 1,000 mbar pressure are possible.

Powder and liquid raw materials may be stored in bulk silos, tanks, or standard delivery containers, and fed on demand to the mixer. The storage or pre-batch tanks allow for compounds to be dispensed by load cells or mass-flow cell metering, and then sent directly to the mixer through a suitable delivery system, depending on the reagents. The entire raw material addition process can be monitored and controlled manually or with an automatic recipe control system.

For certain liquid reagents, it may be necessary to make an intermediate mixing or dispersing step by using Turello pre-mixers before the reagents arrive to the TPM Press Mixer. This provides for the incorporation of powders and a variety of sensitive liquids and reagents.

All of the remaining raw materials in the mixer (both dry and liquid) can be combined using the system’s mixing tool(s). Mixer blade configurations can be single or twin shaft using a separate high-speed disperser mixer option in combination with bar-style mixer incorporation blades. The product viscosity range is 300,000-3,000,000 cP.

Design temperature ranges of 10-95˚C are possible using jacketed heating and cooling systems. Typical batch processing times are 40 min to 2 hrs, but the length of the process can be recipe dependent.

Once the mixing process is finished, the product is pushed out directly from the mixer without opening the mixer chamber and exposing the product to the atmosphere. This is possible because the lower part of the machine includes an extruder cylinder that is attached to a press plate, which also serves as the bottom of the mixer vessel.

At the upper top end of the mixer are the mixing tools, which retract into the mixer cover to form a flat surface when the mixing process is complete. This enables the press plate to make total contact with the top of the mixer cover for complete emptying of the mixer vessel chamber and extrusion of the mixed product.

With compatible or like products, it is not normally necessary to clean the vessel between batch changes with this system. The press plate includes a seal/cleaning system developed by Turello that enables the seal and mixer vessel walls to be cleaned during the extrusion phase of the manufacturing cycle.

When the press plate is activated, the finished product is transferred via a pipeline and stored in a “twin buffer holding tank” system. The buffer tank is a completely enclosed Turello-designed press. This storage buffer/tank/press can also act as the “process pump” to move product to the filling stage. A double-buffer pump can be used for longer transfer distances.

The twin buffer tank system allows for filling/packing from one buffer tank while the mixer is recharging the second buffer. The mixer can fully transfer a full batch into the buffer press in 10 min, creating a virtually continuous and enclosed mixing system. This buffer tank and press design works well when incorporating Turello multi-dosing technology for the automatic, inline introduction of catalysts or pigments, supporting total process and product flexibility.

When combined with the double-buffer tank system, the buffer press generates high extrusion rates for situations where it is necessary to transfer product a long distance between the manufacturing and filling/packing locations. Product is then introduced to the static mixer just prior to automatic filling stations for cartridges, chub sausages, pails, or drums, depending on the production requirements. The press method can provide savings related to capital costs and maintenance when compared to conventional mechanical pumping methods.

Complete Control

Utilizing this design, all of the necessary equipment—from the storage of raw materials to the final filling point—enables companies to have complete control of the entire production process. High overall equipment effectiveness (OEE) levels are attainable, ensuring favorable capital utilization rates and returns on investment (ROIs) that are supportive of investment.

For more information, contact the authors at jcmanter@cimaco-solutions.com (North America) or chriswatkins@cimaco-solutions.com (Europe), or visit www.cimaco-solutions.com or www.turello.net.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!