Mixing Technologies for the Production of Low- to High-Viscosity Adhesives

A number of factors, primarily viscosity and shear input, are considered when selecting the correct mixing technology for an adhesive formulation.

Ross Mixers

Adhesives are formulated from different chemistries depending on their end use and desired performance. The type and amount of resin, curing agent, fillers, and additives are selected to optimize bonding to a particular substrate in a particular environment. In a similar way, the mixing technologies utilized in the production of adhesives also vary from one formulation to another. Mixer selection is based on a number of factors but primarily viscosity profile and shear input.

The ideas discussed in this paper are recommendations based on Ross’ collective experience as a provider of specialty mixing equipment to the adhesive industries. Mixer testing and simulation trials are recommended to confirm the suitability of a specific mixing strategy.

Introduction

The preparation of almost all adhesives begins and ends with adequate mixing. From the homogenization of adhesive emulsions, to the dissolution of polymers into solvents, or mastication of rubber and let-down of master batches, the type of mixing equipment and method hugely dictate overall processing efficiency and end-product quality. This paper seeks to provide an overview of effective and updated mixing technologies being implemented across many of today’s competitive adhesives manufacturing plants, as well as new equipment designs increasingly being recognized by the industry as potential solutions to prevailing mixing challenges.

High Shear Mixers

Early equipment used to dissolve polymers into solvent was based on low-speed propeller, turbine, or rake-type agitators in vessels (known as churns). These devices relied heavily on the solvent’s softening action on the polymers and predictably yielded very long cycle times. Mixing in a churn for as long 12-24 hours was typical. The operator would load the vessel with raw materials, turn on the mixer in the morning and shut it off in the evening or the next day. This problem was exacerbated when the resin was supplied in pellet or slab form, making it difficult to dissolve. Even with the introduction of saw-tooth type high-speed dispersers, batch times could take up to several hours just to dissolve the resin.

To hasten the solvation process, a High Shear Mixer is recommended. Composed of a four-blade rotor that turns at high speeds within a stationary stator, this mixing device will mechanically shear large particles and reduce their size. Materials are drawn from below the mix head and expelled at high velocity through the openings of the stator, creating intense hydraulic and mechanical shear. As fast as material is expelled, more is drawn into the rotor/stator generator. Polymer particles are thus broken down into smaller and smaller pieces, which get easier and easier to dissolve. Fillers too such as fumed silica are dispersed faster with a High Shear Mixer compared to lower-energy devices.

Four-blade rotor/stator High Shear Mixer

Four-blade rotor/stator High Shear Mixer

To illustrate, a manufacturer of PVC solvent cements switched to a Ross rotor/stator mixer from its high-speed disperser and reduced cycle time from four hours to just under 45 minutes when PVC pellets are used, and under 30 minutes when the PVC is in powder form.

Another company making insulation adhesives experienced the same >80% reduction in mixing time when it replaced its disperser with a Ross High Shear Mixer. The batch rotor/stator efficiently tears up pieces of neoprene rubber and rapidly dissolves them into a blend of toluene, hexane, and acetone. The use of a closed and jacketed mix vessel prevents the loss of solvents and also allows the operator to closely control batch temperature.

The High Shear Mixer, available in both batch and inline configurations, is not only useful for dissolving solids into liquids, but also for preparing emulsions. A manufacturer of protective films and tapes used for a variety of surfaces including carpets, windows, marble, and steel was looking for a faster way of blending two liquid components of an adhesive emulsion. They were using a propeller type mixer that they had to run for one hour to ensure that the low-viscosity mixture, made of 95% acrylic emulsion and 5% polyisocyanate solution, was homogenous and had a droplet size of <0.30 microns. Laboratory tests revealed that an inline rotor/stator mixer was able to achieve the desired product characteristics in just a single pass. This translated into a dramatic improvement in mixing time using a relatively small inline mixer.

In a good number of cases, due to the drastic reduction in mixing time, shifting from a low-speed, low-shear mixing system to a high-shear rotor/stator device generates significant savings in energy consumption, which results in a full return of investment within a very short period of time.

Solid Induction Systems

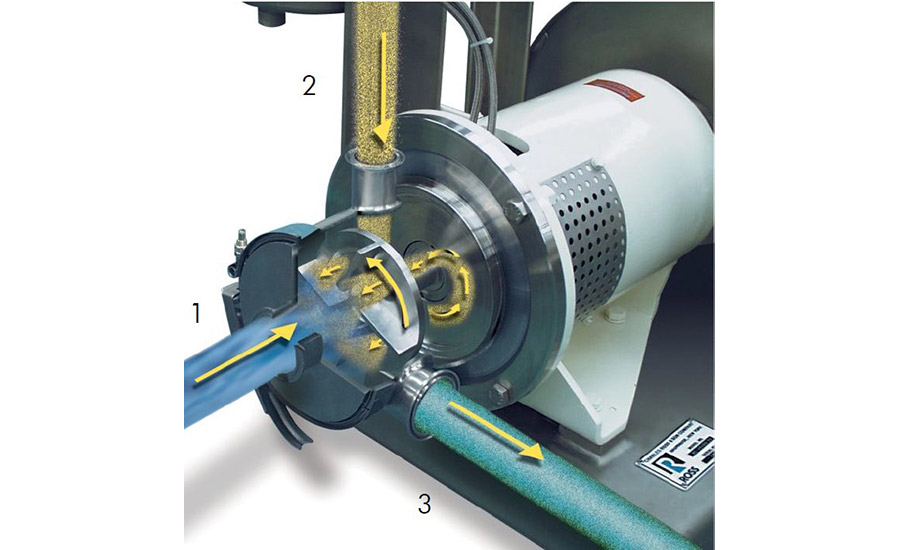

Ross Inline High Shear Mixers with Solids/Liquid Injection Manifold (SLIM) Technology are utilized in continuous or recirculation operations where significant amounts of solids must be added into a low-viscosity liquid. The SLIM consists of a special rotor/stator arrangement designed to create negative pressure behind the rotor, which acts as a motive force for drawing solid ingredients directly into the high shear zone where they are instantaneously mixed with the incoming liquid stream. The resultant mixture is then expelled centrifugally through the openings in the fixed stator before exiting the discharge connection.

The liquid stream (1) enters the mixer and immediately encounters the powder injection (2) at the high shear zone of the rotor/stator assembly. The resulting dispersion (3) is expelled centrifugally through the stator openings at high velocity. After solid components are injected, the mixer may also be used to introduce liquid additions into the mixture.

The liquid stream (1) enters the mixer and immediately encounters the powder injection (2) at the high shear zone of the rotor/stator assembly. The resulting dispersion (3) is expelled centrifugally through the stator openings at high velocity. After solid components are injected, the mixer may also be used to introduce liquid additions into the mixture.

For years, a developer of automotive adhesives and coatings had been using a high-speed dispersion mill to prepare a high-volume adhesive premix. Crumbs of chlorinated rubber, different grades of carbon black, and other fillers were dispersed into a solvent solution. Although adequate in attaining the desired grind prior to the sandmilling step, the dispersion mill was prone to overheating and required a great deal of maintenance. Looking for a better way to prepare its premixes, this company tried a Ross SLIM Mixer at its facility through a trial/rental program. Extensive trials confirmed that the mixer offered a three-fold advantage to the company's dispersion mill: lower processing temperature (85 °F vs. 140 °F), higher solids loading capability (28-33% vs. 8-12%), and faster dust-less powder induction. The 25HP rental unit was consequently converted into a purchase.

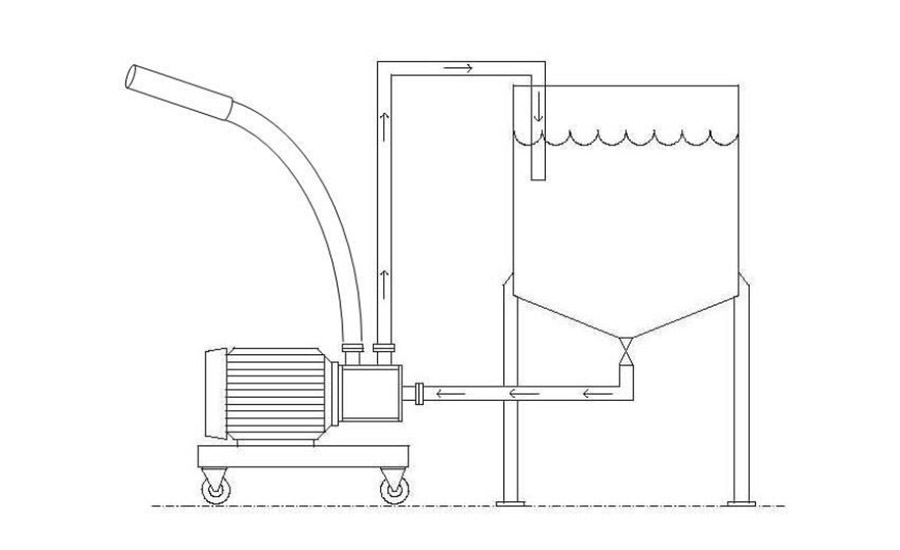

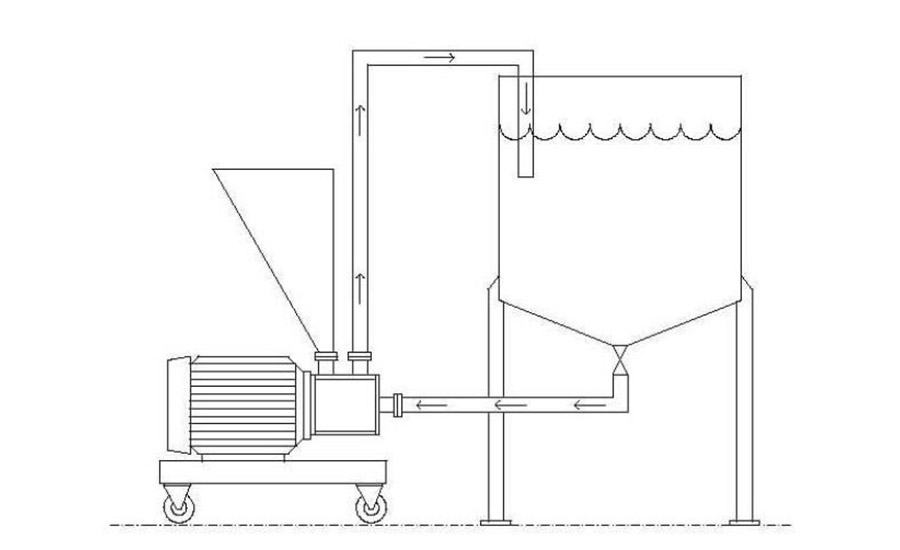

In such a system, powders may be drawn from their original container using a flexible wand connected to the solids inlet port or they may be transferred into a hopper right above the mixing chamber. Still another method of transporting powders to the SLIM is via an automated feeding device such as a bulk bag and feeder combination. Use of the SLIM system greatly reduces dusting in the mixing area.

Flexible hose and wand attachment.

Flexible hose and wand attachment. Hopper attachment.

Hopper attachment.

Application Example:

A producer of pressure-sensitive adhesives was using a steam-jacketed mix tank with a center agitator and counter-rotating sweep blade to disperse rosin ester resin powders into a surfactant-water solution. This process took 5 to 6 hours to complete. Temperature was closely monitored and kept below 113 °F. At higher temperatures, the resin particles would soften and begin to agglomerate into sticky clumps, which affected product quality and made cleaning difficult. When this point was reached, cooling was necessary to reverse the agglomeration.

Evaluation of a 25HP Inline SLIM Mixer with a hopper attachment revealed that resin powders can be inducted under high shear at a rate of around 75lbs/minute. Due to the very short cycle time, the 45% resin mixture is kept well within the limit of 113 °F, and a cooling step is not required.

Other typical solids inducted using this include fumed silica, bentonite clay, calcium carbonate, cellulose gum, CMC, flour, starch, and talc powders.

Ultra-High Shear Mixers

In some instances, even conventional four-bladed rotor/stator mixers are unable to provide the required level of shear for dispersion, emulsification, or particle size reduction. In these cases, manufacturers commonly turn to high-pressure homogenizers or colloid mills to make their adhesive products.

Yet, several issues are typically encountered that make the use of homogenizers and mills less than ideal. These issues include low throughput, labor-intensive and time-consuming clean-up procedures, and high maintenance (i.e. life of seals are relatively short due to the extreme operating conditions). In addition, high-pressure homogenizers have a high initial cost.

A different and welcome approach comes in the form of new generation Ultra-High Shear Mixers, an emerging and very promising technology with applications in various process industries, not just in adhesives production.

Ultra-High Shear Mixers feature unique rotor/stator geometries and tip speeds over 11,000 ft/min. The combination of extremely close tolerances, specially designed channels and grooves in the rotor/stator generator, and high tip speed, produces sub-micron dispersions and emulsions. Just as importantly, this type of mixer disintegrates solid polymers into extremely small particles in just a single pass.

Several new designs of these Ultra-High Shear Mixers represent a quantum leap over the conventional rotor/stator mixer technology. Speed, residence time, and rotor/stator gap setting can be adjustable to prevent over-shearing.

New designs in the Ultra-High Shear Mixers.

New designs in the Ultra-High Shear Mixers.

In the manufacture of adhesive emulsions, Ultra-High Shear Mixers, compared to lower energy devices, produce finer droplet sizes and may allow the use of less surfactant, which in turn can reduce the cost of the end product. One problem associated with wetting agents and defoamers is that they can be adsorbed by the polymer particles, thereby altering the coating performance of the emulsion. This often leads to product rework and/or scrap. Thus, by using less surfactants and defoamers, one can save in raw material costs and also produce more consistent batches.

Multi-Shaft Mixers

Generally, the bulk of the solid portion of an adhesive is the bonding agent and the solvent is only a carrier to provide an easy method of application. Therefore, adhesives with a higher solids percentage usually contain more usable adhesive per gallon. Many adhesive slurries, cements, and pastes are high-solids, viscous formulations that cannot be processed in a disperser or rotor/stator mixer. This is when Multi-Shaft Mixers are employed.

Multi-Shaft Mixers are comprised of two or more independently-driven agitators working in tandem. A low-speed anchor compliments one or two stationary high-shear devices (a high-speed saw-tooth blade and/or rotor/stator assembly). On its own, a disperser blade will produce acceptable flow patterns for products around 50,000 cP maximum; the rotor/stator’s recommended viscosity limit is even lower, around 10,000 cP. Hence, there is a need for a supplementary agitator to improve bulk flow, deliver viscous product to the high-shear devices and constantly remove product from the vessel walls for better heat transfer.

The most common low-speed agitator designs are the two-wing and three-wing anchors. For added efficiency, especially in terms of axial flow, the three-wing anchor can be modified to feature helical flights in between the wings. Multi-Shaft Mixers typically process adhesive formulations with a viscosity of several hundred thousand centipoise.

1000-gallon Triple-Shaft Mixer with dual-post hydraulic lift.

1000-gallon Triple-Shaft Mixer with dual-post hydraulic lift.

Aside from the extended capability of Multi-Shaft Mixers from a viscosity standpoint, another design advantage is that they are closed systems that offer the benefit of mixing under vacuum or pressure.

When processed under vacuum, certain adhesives and composites develop higher densities and possess better tensile properties as a result of improved shearing and contact of the different components. With other adhesive products, vacuum mixing keeps entrapped oxygen to the minimum, which ensures longer shelf-life and improved stability. This is sometimes done in conjunction with nitrogen blanketing. Mixing under vacuum gets rid of unwanted voids that agitation under atmospheric conditions can produce. Pulling vacuum while mixing can also eliminate costly downstream deaeration steps and shaves overall processing time.

It is common for Multi-Shaft Mixers to function as specialized reactors equipped with automated controls and PLC-based recipe systems. For example, in a polymerization reaction, the batch has to be kept constantly homogenous and carefully monitored for temperature, level, pressure, etc.

The properties of the end product are directly influenced not just by the purity of raw materials and reaction chemistry but also by the efficiency of mechanical mixing. Undoubtedly, identical formulations produced in different mixing systems can result in dissimilar stability, adhesion performance, temperature resistance, and other critical properties.

Planetary Mixers

Adhesives processed in extremely viscous states can readily surpass the limits of Multi-Shaft Mixers. For instance, the low-speed anchor in a Multi-Shaft Mixer may reach a point where it can no longer produce adequate flow — it simply carves a path throughout the batch instead of pushing product away from the walls and into the center. Consequently, high-temperature zones right near the disperser and rotor/stator assemblies begin to form. At this point, stationary agitators no longer suffice, and a move to a planetary mixer is required.

The agitators of a planetary mixer rotate and travel throughout the mix vessel, passing every point within the batch, not just along the periphery. Highly viscous materials are literally carried from the vessel wall to the batch interior. In essence, a planetary mixer provides powerful kneading and mixing action regardless of the product’s flow characteristics.

The classic Double Planetary Mixer is a standard machine in the manufacture of adhesives. It can be equipped with traditional rectangular stirrer blades, finger blades or high viscosity (HV) blades. The latter is a patented blade design that generates down-thrust mixing due to its precisely angled helical contour. The sweeping curve of the HV blades firmly pushes material forward and downward, a unique mixing action that solves the “climbing” problem commonly experienced when processing highly-filled adhesives. In addition, the HV blades do not have a lower crossbar so they can be lifted cleanly off a very viscous batch and also pierce right through one just as easily.

Double Planetary Mixer with HV blades (US Patent No. 6,652,137).

Double Planetary Mixer with HV blades (US Patent No. 6,652,137).

The order of raw material addition in a Double Planetary Mixer is a crucial parameter. Its agitation mechanism is relatively low speed but very thorough and does not require a minimum batch level to properly melt solids or wet them out with a small amount of liquid. A typical batching procedure, for the most part, involves mixing and kneading a highly viscous paste or putty-like material until the desired level of dispersion is achieved. A let-down step is then performed towards the end of the mix cycle.

There are adhesive products that require a two-step approach to assure proper dispersion. For instance, after blending all ingredients in a Double Planetary Mixer, the entire batch is transferred to a single-shaft, high-speed disperser to provide the extra shear needed for completion. This cumbersome, two-step process is labor-intensive and time consuming. To improve production efficiency, manufacturers can utilize a hybrid Planetary Disperser that combines the traditional thorough mixing action of a planetary mixer with the added benefit of a high-speed disperser. Both the planetary blade and the high-speed disperser rotate on their own axes while revolving around a central axis. The planetary blade orbits through the mix can in a circular manner, continuously sweeping the vessel walls, as well as the vessel bottom, and carrying material toward the high-speed disperser. The planetary blade also insures that any heat created by the disperser is evenly distributed throughout the mix. Variable speed allows precise control of shear rates to minimize the degradation of any shear-sensitive components.

Like Multi-Shaft Mixers, Double Planetary Mixers and Planetary Dispersers used in the production of adhesives benefit from vacuum processing capabilities for the same reasons: to minimize exposure to oxygen, remove unwanted voids, and improve dispersion. In this aspect, vacuum-rated planetary mixers designed for high-viscosity processing offer advantages over traditionally accepted atmospheric design horizontal sigma blade mixers.

Kneader extruders and double-arm sigma blade mixers are high torque machines that can muscle through hard blocks of rubber. They remain the most powerful tools for manufacturing extremely viscous adhesive formulations. However, there are several considerations that make planetary mixers a better choice for certain applications.

One of those considerations is that a horizontal mixer can be too powerful and degrade shear-sensitive components such as fibers. In addition, this type of mixer relies on the product being highly viscous at all times in order to mix properly — liquid components must be added very slowly, portion by portion, or else they can act like a lubricant and reduce shearing efficiency. A vertical planetary mixer is more flexible in this regard. Other comparisons include:

Easier Cleanup

A planetary mixer has no shaft seals, bearings, packing glands, or stuffing boxes submerged in the product zone. In addition, the agitators are raised and lowered in/out of the mix can by a hydraulic lift. This allows easy access for cleaning between batches.

Interchangeable Blade Designs

Rectangular Blades — Proven choice for many low- to high-viscosity mixing applications. These blades are also used in dry blending, granulation, and vacuum drying processes.

Finger Blades — Often preferred for special applications that require the mixing of delicate fibers and solids. This design may also be fine-tuned for custom axial flow mixing requirements.

HV Blades — Patented Ross design used for ultra-high-viscosity mixing applications up to around 6 million cP.

Less Floor Space Required

Footprint of a vertical Double Planetary Mixer or Planetary Disperser is considerably less than that of a horizontal double-arm/sigma blade mixer of the same working capacity.

Energy Savings

Planetary mixers use less horsepower to operate, and the energy savings can be significant over time.

Semi-Continuous Operation

With the use of multiple interchangeable mix cans, a planetary mixer can produce material in a semi-continuous basis: one vessel may be charged with raw materials while another can is under the mixer, and still another is being discharged and cleaned.

Lower Cost

Depending on specifications, a planetary mixer is generally one-half to one-third the cost of a comparably sized new sigma blade/double-arm mixer.

Value of Testing

A manufacturer of corrosion-resistant, trowellable adhesives had developed a new line of two-component adhesives. At that time, six different mixes were being produced in laboratory scale, and the production plant intended for the new line was just being built. A large order came in, and engineers had to scramble to get the production equipment.

The adhesive products were relatively viscous (700,000 to 1,500,000 cP) and difficult to handle. Attempts to mix it properly in the plant’s existing sigma blade mixer were not successful — the product had too many voids and there was evidence that the reinforcing fibers were being degraded.

A test run in the Ross Test & Development Center confirmed that a Double Planetary Mixer was appropriate for the application. The adhesive company rented a production-scale unit for further evaluation at its plant. Burnout tests and visual examination showed that the planetary mixing action did not degrade the reinforcing fibers in the mixture. The resulting product possessed the required high strength and exhibited maximum tensile properties.

The mixer performed very well and the plant decided to keep it, as well as purchase two extra mix cans to implement semi-continuous production. Once a mix is finished in one vessel, it is taken to the packaging area for emptying while another mix can is positioned under the Double Planetary Mixer. During production, the plant tries to reserve a can for each recipe. As long as the components are not being changed or left in the vessel longer than specifications permit, cleanup can be avoided. The planetary blades are easily cleaned by lifting the mixing head and wiping them with the appropriate solvent.

Conclusion

The success of modern adhesive chemistries can only go so far as our capability to produce them cost-effectively. It is essential for process engineers to be updated on the different mixing technologies that are being improved or made available. Many mixers overlap in use and function such that certain applications can actually be successfully produced in more than one distinct mixer design. For example, many types of epoxy-based adhesives, contact cements, hot melts, and pressure-sensitive adhesives can be made in heavy-duty Multi-Shaft Mixers, Double Planetary Mixers, and Planetary Dispersers. In these cases, economics rules out the more costly initial investments but engineers must also take into account the differences in efficiency, cycle time, cleanability, ease of maintenance, etc.

A visit to a mixer manufacturer’s test center will be very helpful and will make your selection process easier. Be sure to test a variety of equipment and techniques using your own raw materials, simulating conditions as close to your actual process as possible. Quantitative test results provide the best assurance that you have chosen the best mixing system for your particular adhesive product.

Learn more at www.mixers.com.

White paper courtesy of Charles Ross & Son Co.

Article images provided by Charles Ross & Son Co.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!