Advancing Adhesives

Legislation on GLYMO Will Shape Packaging in 2020

Epoxy silanes like GLYMO and GLYEO are adhesion promoters used in food packaging, but safety issues have prompted the development of new alternatives.

Consumers expect the food industry to provide safe products that comply with the latest regulations. FEICA, the Association of the European Adhesive and Sealant Industry, recommends avoiding the use of epoxy silanes in food contact applications, and the European Union is expected to set new limits during the course of this year. These limits will require complex testing methods that lead to challenges for converters and packaging manufacturers.

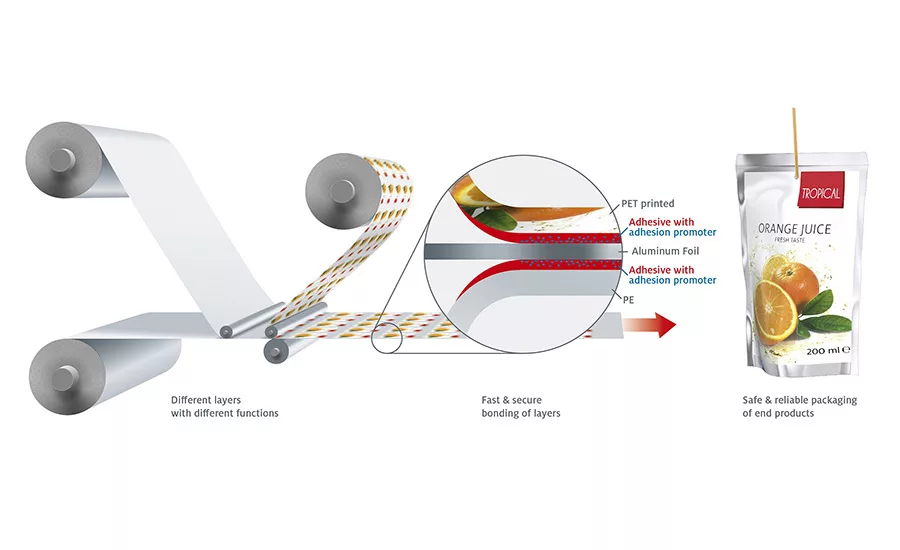

Epoxy silanes, like [3-(2,3-epoxypropoxy)propyl]trimethoxysilane (GLYMO) and [3-(2,3-epoxypropoxy)propyl]triethoxysilane (GLYEO), are adhesion promoters used in food packaging for applications such as laminated pouches that must be resistant to sterilization and hot filling. In some cases, they are also used for microwaveable packaging. These adhesion promoters have several favorable attributes, which is why they can be found in a variety of applications. They increase the adhesion between aluminum and polyolefin films and maintain the bond strength even at elevated temperatures.

Due to the fact that GLYMO is used in a variety of food contact applications, the European Food Safety Authority (EFSA) had a closer look at existing toxicological data. In 2017, EFSA concluded that GLYMO must be considered to have a genotoxic potential.

“Therefore, the European Union is now working on a legislative framework for 2020 to regulate the use of epoxy silanes according to their genotoxic potential,” said Monika Toenniessen, Ph.D., Henkel’s head of Food Safety Compliance-Global Food Safety, Product Safety and Regulatory Affairs. “The deadline is envisaged for September 2020. This will raise demand for suitable alternatives.”

Changes Required for the Whole Industry

In the near future, the application of GLYMO as an adhesion promoter will still be permitted as long as it can be demonstrated that it does not endanger human health. Products containing epoxy silane are not permitted to be used for fatty filling goods, and epoxy silanes must not be detectable in aqueous filling goods.

“The critical part, however, will be that converters and packaging manufacturers need to provide proof for the absence of GLYMO and structurally similar chemicals such as GLYEO,” said André Weiss, Ph.D., manager of Instrumental Analytics, Project Management Food Safety for Henkel. “This implies two factors: having the right adhesive and the right testing method to prove it.”

Providing Suitable Alternatives

Henkel reports that it anticipated this development and worked to develop epoxy silane-free adhesives. These systems, which are specifically designed for high-temperature food contact and medical retort applications, are modular in their design. The adhesive base, Loctite Liofol LA 2798, can be combined with a variety of hardeners, making it versatile and reducing complexity for converters. Henkel currently offers four hardeners, each with different features to cover a range of applications.

For dried animal food or hot filling goods, Henkel provides two aromatic hardeners for boiling and pasteurization. These medium-high performance systems can be cured at room temperature and are designed for high temperature resistance and high heat-sealing strength. For high performance, Henkel offers an aliphatic hardener for general retort. It cures at room temperature and is recommended for 45-min sterilization processes at 134°C, making it an adhesive option for applications involving products such as baby foods.

Another option has been developed for the packaging and sterilizing of liquid, particularly aggressive filling goods such as fatty foods and oily fatty contents such as cat food. This system is designed for processing temperatures of 134°C for 45 min, and its modularity enables customers to reduce complexity while providing flexibility.

Henkel reports that the adhesion properties and performance of these GLYMO- and GLYEO-free adhesive systems have been confirmed during industrial use. The products offer an effective opportunity to be on the safe side of the epoxy silane discussion early on.

For more information, visit www.henkel-adhesives.com/uk/en/glymo-free.

Editor's note: Listen to our podcast with Alexander Bockisch, Henkel's global head of market strategy, Lamination & Coatings, who discusses GLYMO, GLYEO, and various issues surrounding these materials.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!