Bio-Based Materials for Adhesives and Sealants: The Sustainability Revolution is Here

Fostering the bio-economy requires new technology that pushes the boundaries of bio-based performance.

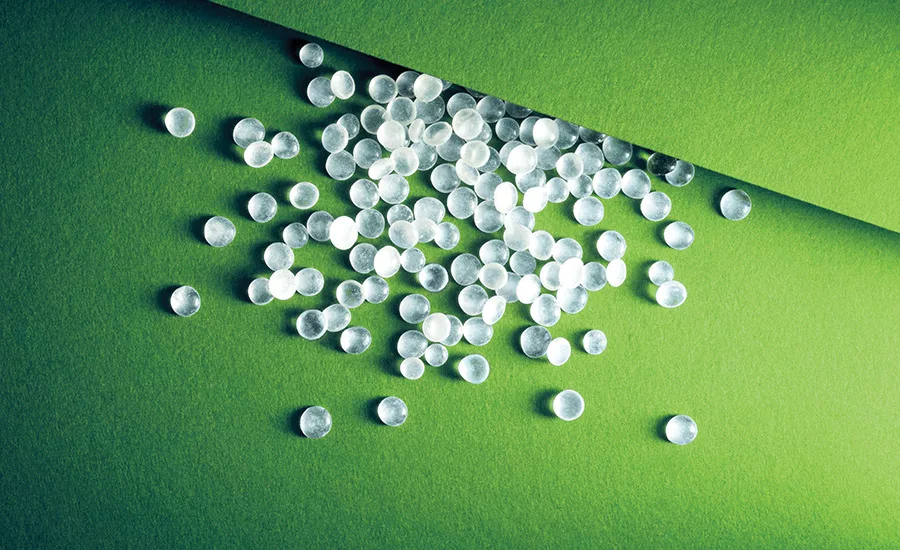

New rosin ester technology enabled by a novel catalyst class allows for the production of near water-white rosin esters.

By 2050, the United Nations expects the global population to reach approximately 9.5 billion people. The expectations are that millions of people will be lifted out of poverty, increasing living standards and driving demand for chemical products. However, this growth also forces governments and businesses to address the population’s need for food, housing, infrastructure, and mobility in a resource-constrained world. This means chemical manufacturers must offer safer, more sustainable products with less environmental impact while delivering equivalent or greater performance compared to fossil fuel-based products.

The amplified demand for sustainability creates opportunities for the adhesives industry to deliver on products of the future. This includes renewable, responsibly sourced materials that further enable the bio-economy and address global challenges like climate change. Pine chemicals, for example, are sustainable from a material perspective while also being responsibly sourced and processed throughout the entire value chain.

Chemical companies offer tackifiers sourced from pine trees, which are often grown in responsibly managed forests and are harvested for the timber and paper industry. Through a chain of custody, the paper industry controls the pine trees’ origin. When converting pine trees into paper or cardboard, the sap (called crude tall oil, or CTO) must be removed to allow conversion into paper pulp.

From the pulp mill, the CTO is transported to a bio-refinery, where it starts the process of being produced into different bio-based products. Instead of wasting this side stream, suppliers convert CTO into value-add materials that can be used in many applications.

Unlike other renewable-based products such as soy or palm, pine tree forests do not compete with land needed for food production, nor do they need new agricultural land. This leads to a significantly lower carbon footprint for many of the resulting bio-based products.

Once it goes into the bio-refinery, CTO is refined and upgraded into different fractions, such as tall oil fatty acid, tall oil rosin, distilled tall oil, and pitch. From there, these fractions can be upgraded into a wide range of bio-based chemicals that make up the building blocks in various applications, such as rosin esters for hot-melt adhesives or pressure-sensitive adhesives.

Raising the Performance Standard for Bio-Based Materials

For years, the chemical industry has offered the adhesive industry tackifiers made from fossil fuels and bio-based sources, such as rosin esters. Rosin esters have been increasing in popularity because their polarity and polymer compatibility allow for excellent specific adhesion to a wide range of substrates.

In principle, rosin esters are more complex than their hydrocarbon counterparts since they have a higher degree of functionality. This can make the purification steps more complex, with different integrated processing required to optimize product yield, quality, and consistency.

Since rosin esters are a natural-based product, there are some challenges in stabilizing the material. The market demand for lighter and more stable materials is increasing as a result of the general perception that lighter color reflects better product quality. Traditionally, these characteristics are more easily achieved using hydrocarbon-based products.

While various technologies enable rosin ester production with high oxidative stability, there are still shortcomings regarding resin color. Some iterations have been made over the years, but the basic chemistry has not changed significantly. Meanwhile, there is a need for rosin ester chemistry to enable the cost-effective production of products with improved color and oxidative stability. One of the most recent discoveries is rosin ester technology* that is enabled by a novel catalyst class, allowing for the production of near water-white rosin esters.

This technology allows the production of rosin ester with up to 1.8 G reduction in neat color combined with oxidative stability. Both of these benefits are critical parameters that are required in various industries, such as adhesives and road marking. The ability to meet these performance requirements will drive further demand for sustainable solutions.

Initial lifecycle assessments indicate that—from cradle to gate—the new rosin esters made from this technology produce less than half the carbon dioxide emissions of the hydrocarbon alternative. This substantial reduction in carbon footprint appeals to manufacturers looking to reduce environmental impact.

Elevating Performance

With an increasing demand for sustainability throughout the value chain and advanced technology allowing for greater advantages in bio-based materials, the need for sustainable solutions is only growing. Pressure from governments, customers, and consumers is requiring adhesive producers to continue elevating performance while reducing environmental impact. Companies that take the necessary steps early on and make the transition to bio-based materials will be well-positioned to meet the market demand—now and in the future.

For more information, contact the author at peter.migchels@kraton.com or visit www.kraton.com.

Listen to our conversation with the author on the Bonding with ASI podcast!

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!