Pressure-Sensitive Glazing Tapes for Window Fabrication

Residential and commercial window manufacturers depend on pressure-sensitive tapes to provide immediate handleability and increased throughput during fabrication.

Pressure-sensitive glazing tapes form a bond and seal between an insulated glass unit (IGU) and a framing system, window sash, or door. The term “glazing tape” is used throughout the residential and commercial fenestration industries but can mean different types of products to different end users.

Structural Glazing Tapes

Structural glazing tape is made from a 90-mil, high-strength, monolithic, foamed acrylic adhesive system. Designed to replace structural silicone sealants, it is used in curtain wall, window wall, ribbon window, storefronts, and entrance door systems.

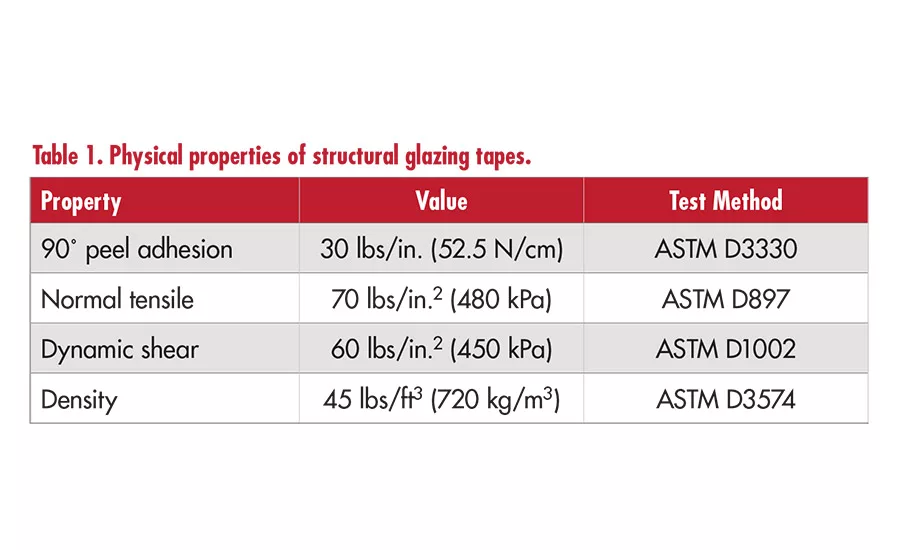

The acrylic foam is viscoelastic and provides excellent elongation properties, allowing it to resist sudden and varying wind loads (see Table 1). End users of structural glazing tape benefit from immediate handling strength (glazed units can be handled immediately), no mixing or curing or liquid adhesives, reduced labor costs, clean appearance from the interior side of the glass, and consistent thickness and width.

Structural Spacer Tapes

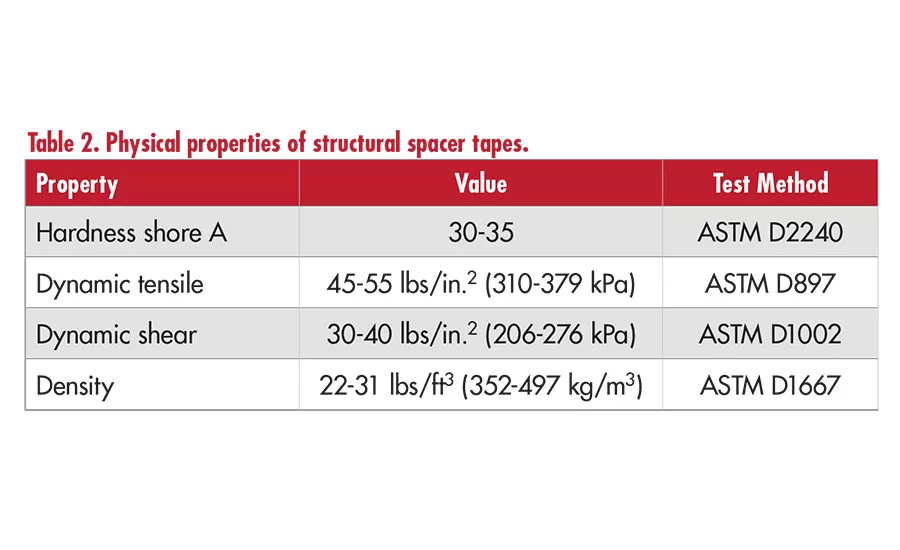

Structural silicone glazing (SSG) relies on a structural silicone sealant working in tandem with tape. This glazing methodology has been in use for window wall and curtain wall systems since 1979. The spacer tape provides a consistent gap between the IGU and the framing system so the correct amount of structural sealant can be gunned into the channel to meet the design guidelines for the IGU weight, wind loads, and thermal expansion.

The structural spacer tape is made from a semi-rigid, open cell, polyurethane foam core coated with an acrylic adhesive system on one or two sides. The open cell structure allows air and moisture to reach the sealant so optimum cure and maximum bond strength can be achieved. Key benefits of these systems include:

- Semi-rigid foam spacer maintains the gap between the glass and frame

- Spacer tape is compatible with structural silicone adhesives

- Adhesive on two sides allows for positioning and securing of the panels; this stabilizes the glass during the curing cycle and prevents silicone from overflowing into the vision area

- If no adhesive on the glass side is desired, adhesive can be applied on one side to replace silicone-compatible rubber profiles; a coating on the non-adhesive side facilitates easy glass positioning

- Vapor permeable due to open cell foam core to allow rapid silicone cure

Residential Window Glazing Tapes

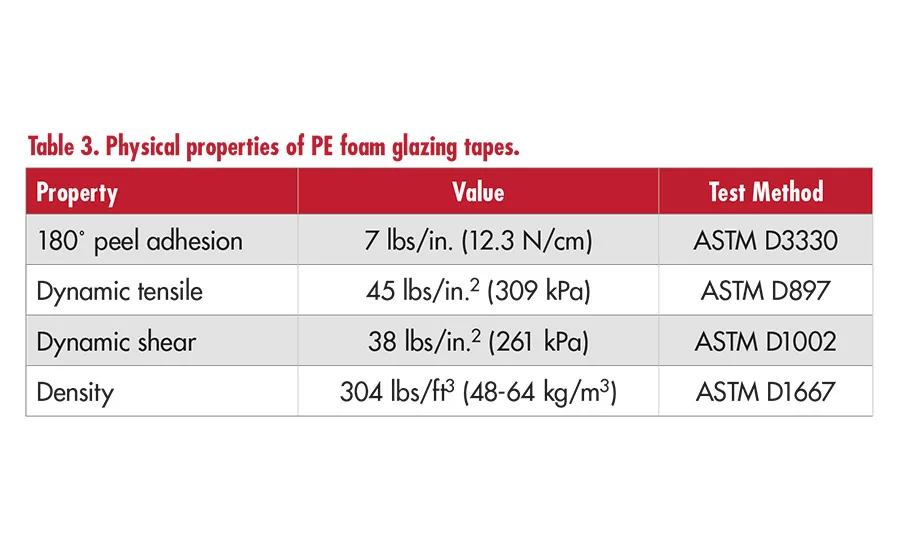

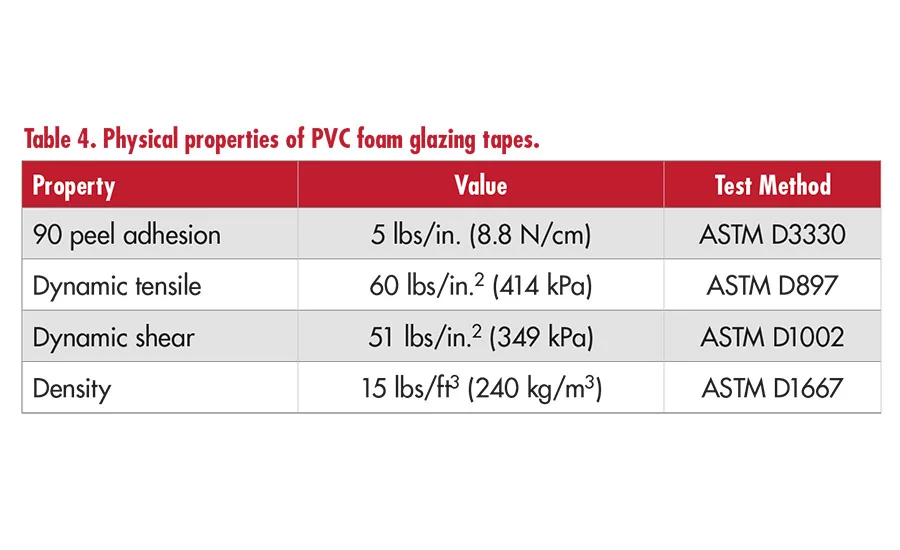

Manufacturers of residential and light commercial windows utilize glazing tapes made from a polyethylene (PE) or polyvinyl chloride (PVC) core that has been coated with an acrylic adhesive system. These lower density materials are easier to compress to form a seal between the sash and the IGU. A decorative glazing bead is typically pushed into the sash that puts the tape under compression. These tapes are more economical than the commercial glazing tape products and are well-suited to the lighter IGUs common to residential windows.

The adhesive systems on these tapes are designed to adhere to framing systems made from PVC, painted metal, and fiberglass. The foam core will seal against air, water, and contaminants if they are compressed 30% of their original thickness. Additional benefits include a double-sided tape that allows for fast and easy assembly, uniform sight lines, no cold flow or oozing of sealant into the sight line, and excellent resistance to weathering and UV exposure.

Dependable Solutions

Residential and commercial window manufacturers depend on pressure-sensitive tapes to provide immediate handleability and increased throughput during fabrication. Tape’s ability to bond and seal in one step by itself or to work synergistically with a sealant enables the manufacturer to produce a high-quality window that has improved appearance and aesthetics and meets the environmental demands of the building envelope.

For additional information, visit https://tombrowninc.com.

Watch our interview with the author in this ASI Insider!

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!