Enabling Greener Formulating Innovations with Liquid Polybutadiene Technology

Liquid polybutadienes can help improve the environmental performance of a diverse range of chemical formulations.

The chemical industry continues to strive for greener innovation, and liquid polybutadiene technology* can provide innovative solutions for today’s challenges. High-performance liquid polybutadiene chemistry serves a range of sectors, including automotive sealing and sound damping, rubber compounding, and coating additives.

Liquid polybutadienes can help improve the environmental performance of a diverse range of chemical formulations, many of these within transportation markets. Having a positive impact on sustainability and the environment can take many forms, including the reduction of harmful emissions, lower CO2 from manufacturing processes or vehicles in use, less hazardous materials in manufacturing operations, and making products more durable and extending their life.

Sustainable Benefits in Automotive

Liquid polybutadienes have been used for many years as the functional base in automotive body-shop flexible gap fillers, semi-structural adhesives, and acoustic deadeners. In addition to providing formulators with a range of performance characteristics, from flexibility to adhesive strength, the acoustic damping properties of liquid polybutadienes can extend to the paint shop application of liquid-applied spray dampers.

A traditional approach to sound damping in automotive has been to use filled and plasticized bitumen sheets, placed in contact with the bodyshell during final assembly. However, this method is labor intensive and does not readily permit spot application of the damping material where it is really needed on the bodyshell. These sheets also add unnecessary weight to the vehicle and consume additional materials.

In contrast, a spray-applied acoustic damper based on liquid polybutadiene can be spot applied precisely onto the bodyshell in the assembly line and with automated equipment. The liquid damper is cured in the paint shop oven during assembly, so it reduces emissions over the service life by adding less weight than bitumen sheets while also requiring no additional energy demand to cure.

With increasing focus on reducing the use of hazardous materials in both industrial and domestic environments, the non-hazardous nature of liquid polybutadienes is a further potential benefit for formulators. Sulphur vulcanization of automotive body shop materials is a well-established and versatile technology, but the development of alternative cure systems based on peroxide can reduce the number of components in the formulation that attract specific hazard labelling. Liquid polybutadienes can play an important role in such formulations by acting as plasticizers, crosslinking additives, and direct-to-metal adhesion promoters without contributing to emissions or additional chemical hazards.

Conserving materials and saving energy are key goals in sustainable manufacturing, and they are often achieved by designing products with a longer service life. In the automotive industry, improvements in bodyshell corrosion protection have enabled longer corrosion warranties to be provided, helping to extend the life of the vehicle.

While primer coatings applied in the e-coat bath provide effective metal protection, adhesives, sealants, and dampers required as part of body shell construction are applied directly to bare metal, usually before the removal of anti-corrosive oils. Any failure in the bonding of these compounds allows a route for corrosion to access the unprotected metal surface beneath.

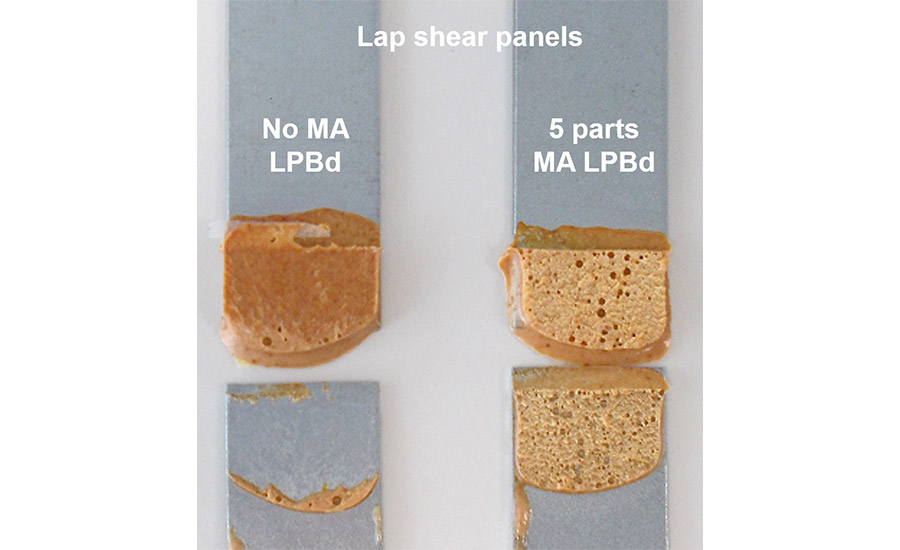

Body shop products based on liquid polybutadienes coupled with maleic anhydride functional polybutadienes play an important part in this protective function. The hydrophobic properties ensure the compound is not washed off prior to the e-coat primer application, and the polar maleic anhydride adhesion promoters ensure good adhesion direct to oiled, bare metal surfaces. This develops a strong, impermeable, and durable bonding of the body shop adhesives and sealants once vulcanized, preventing a route for the onset of corrosion.

Figure 1. Lap shear tests contrast sealant cured with (right) and without (left) maleic anhydride-containing liquid polybutadiene.

Figure 1. Lap shear tests contrast sealant cured with (right) and without (left) maleic anhydride-containing liquid polybutadiene.

Non-Hazardous Modifiers for Rubbers

Beyond direct automotive assembly, liquid polybutadienes play an important part in auxiliary components based on rubber. While largely unseen, these polymers are formulated in a diverse range of rubber components, from engine mounts, cooling hoses, drive belts, and oil seals to the tires’ tread compounds. Many auxiliary chemicals are regularly used in rubber compounds to enhance properties, but many carry hazard classifications and are potentially harmful to health or damaging if released to the environment.

Liquid polybutadiene polymers perform a wide range of functions as rubber modifiers, co-curing during the vulcanization process to increase the compound’s crosslink density. This can improve a range of properties, from better compression set in engine mounts and gaskets to lower Tg to enhance wet grip in winter tire tread. In reinforced belts and hoses, where bonding of the rubber matrix to a textile or metal cord reinforcement is critical for durability, the polar maleic anhydride groups on certain liquid polybutadiene grades provides a significant improvement to the bond strength between rubber and reinforcement.

While these functional properties are obviously of great value to achieve a given specified performance, the use of these liquid polymers also provides sustainability and environmental benefits. During compounding, liquid polybutadienes can help reduce mix viscosity and shorten mix cycle times, providing an energy-saving potential. They can also, in part, replace some of the process oils used in many rubbers. Importantly, thanks to their reactive structures, they are chemically bound into the rubber matrix after cure. While acting as reactive plasticizers during processing and preventing embrittlement over service life, this also means that they cannot leach out into the environment during or even beyond their service life.

For more information, visit www.synthomer.com/lithene.

*The liquid polybutadiene technology discussed in this article is Synthomer’s Lithene™.

Note: Images courtesy of Synthomer.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!