Enabling Sustainable Solutions for Packaging Hot Melt Adhesives with Functionalized Polyolefin Elastomers

The use of low-viscosity polyolefin materials in HMA formulations can lead to increased cost savings and lowered carbon footprint.

image courtesy of Dow

Hot-melt adhesives (HMA) are formulated systems with extensive use in packaged goods, particularly in the bonding of cardboard boxes. This type of system requires the application of a formulation that includes polymer, tackifier, and wax in the molten state, which, due to its low viscosity at the application temperature, spreads over the substrate and rapidly solidifies to make the bond. Polymer is critical in providing cohesive strength, thermal stability, and good performance across a wide range of temperatures. Among the polymers used in packaging HMA formulations, low-viscosity polyolefin materials commercialized by Dow as AFFINITY™ GA Polyolefin Elastomers have demonstrated superior adhesion, improved low application temperature, ease of processability, and thermal stability versus EVA based formulations. This performance translates to increased cost savings and also lowered carbon footprint for the HMA user (Figure 1).

The HMA industry has been moving towards solutions that are safer, more efficient, and have a lower carbon footprint. This move results in three prominent changes in the space: substrate changes, regulatory shift towards safer materials, and the need for higher biobased content.

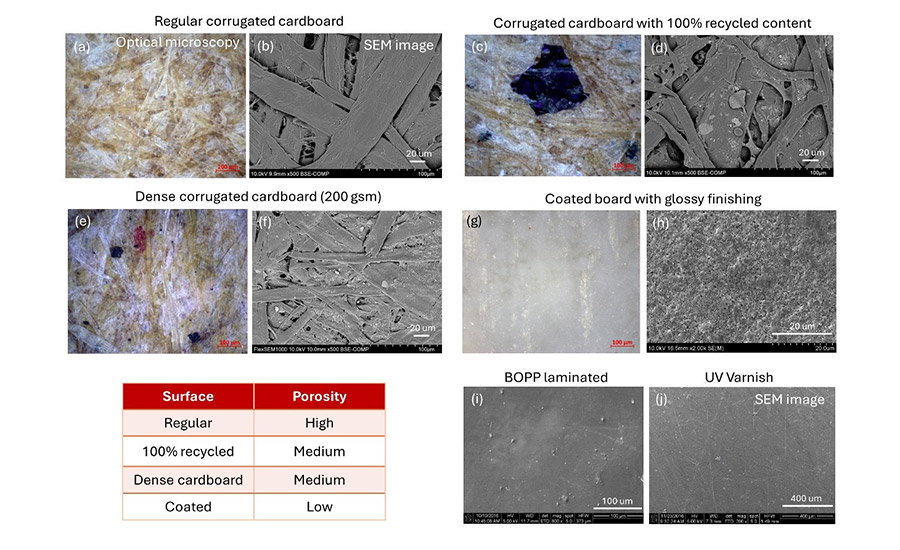

First, the emphasis on sustainability has driven substrates to include higher recycled content and various surface coatings for improvement in quality, functionality, and appeal in packaging. Recycled boards have reduced fiber length and increased contaminants on the surface (Figure 2). The recycled materials may also contain mineral oil aromatics. While this recycled board is suitable for some case and carton applications, the German Ordinance on Consumer Goods establishes limits on the transfer of mineral oil aromatic hydrocarbons (MOAH) from food contact materials (FCMs) made from recycled paper. It specifies that a functional barrier will be required in paper, paperboard, and cardboard for FCMs containing recycled paper, which ensures that no aromatic mineral oil hydrocarbons are transferred from the FCMs to the food. Thus, coatings are common with increased recycled content in addition to applications that require a better visual appeal. Such cardboards are usually coated with bi-axially oriented polypropylene (BOPP), or wax, or glossy oil prints that are difficult to adhere to, due to their polar nature and/or lower porosity (Figure 2).

To address these limitations, Dow launched a low-viscosity maleic anhydride (MAH) functionalized polyolefin, AFFINITY GA 1000R Functionalized Polyolefin Elastomer. The MAH functionalized polyolefin addressed a need in the marketplace and may be considered as having a positive influence on recycling rates in that it enables bonding of cardboard that has an increased level of recycled content. However, as recycled content changed, so to the regulatory environment changes. Residual MAH in products can be subjected to labeling requirements depending on the level in the final product. For example, the 13th ATP of the EU Classification and Labeling Regulation (CLP), which was implemented on May 1, 2020, indicates that if the residual MAH level is greater than 1 ppm the following supplemental labeling phrases apply: [EUH208 - Contains Maleic Anhydride. May produce an allergic reaction].

Also, mineral oil is used in the production of the low-viscosity MAH functionalized polyolefin launched by Dow in 2012. The oil is an ECHA (European Chemicals Agency) approved food-grade mineral oil. Over the years, safety concerns have begun to be raised that consumers could be exposed to mineral oil hydrocarbons in foodstuffs thought to be from mineral oil from printing inks used on graphical/newsprint paper. This created an opportunity to improve the polyolefin elastomers offering.

Responding to industry and consumer demands for safer material, Dow developed the next generation product, AFFINITY GA 1001R POE, enabled by proprietary process improvements. This new Functionalized Polyolefin Elastomer is mineral oil free and has lower MAH residuals. These updates allow the new product to meet the changing safety and regulatory needs of the HMA industry residuals. These updates allow the new product it to meet the changing safety and regulatory needs of the HMA industry (Figure 1).

Due to its unique polymer design, the next-generation product, just like its previous version (Figure 3) offers superior adhesion performance compared to its non-functionalized counterpart on hard-to-bond substrates (Figure 4).

To improve the product carbon footprint, there has been an increase in the demand for biobased raw materials in the HMA formulation. For the polymer component, the biobased AFFINITY RE Polyolefin Elastomers portfolio introduced to the market in 2020 gives formulators polymer options. These polymers are produced using bio-circular feedstocks derived from sources such as used cooking oil. For the tackifier component, biobased natural tackifiers such as rosin and terpene resins have existed for several years. The majority of these tackifiers are polar, which limits their usefulness with the polyolefin polymers, which are inherently nonpolar. In addition to improving adhesion performance, the MAH functionality and low viscosity of AFFINITY™ 1001R enables compatibilization to polar natural tackifiers (Figure 5).

Summary

Dow’s low-viscosity polyolefin materials have unique properties, especially adhesion, due to a combination of low density, low molecular weight/low viscosity and in some grade’s polar functionality. Dow’s MAH functionalized grade adds to the HMA formulators toolbox and enables sustainable solutions based on circularity and low carbon footprint. Using AFFINTYTM GA 1001R-based HMA formulations it is possible to enhance adhesion to carboard with higher density, higher recycle content and shorter fiber lengths, and several other coated substrates. With Dow’s MAH functionalized polyolefin it is possible to formulate HMAs with increased renewable bio-content using polar rosin esters tackifiers. Further, the new version of MAH functionalized polyolefin meets regulatory requirements by being mineral-oil free and having lower residual MAH.

Learn more about Dow at www.dow.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!