Home » Keywords: » elastomers

Items Tagged with 'elastomers'

ARTICLES

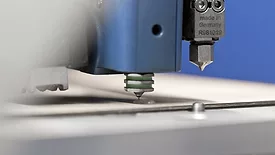

Enabling Sustainable Solutions for Packaging Hot Melt Adhesives with Functionalized Polyolefin Elastomers

The use of low-viscosity polyolefin materials in HMA formulations can lead to increased cost savings and lowered carbon footprint.

September 22, 2024

New Acrylic Block Elastomer for Adhesive Applications

Developed using proprietary living anionic polymerization technology, a new acrylic thermoplastic elastomer is suitable as an adhesive for masking tape, packaging, surface protection film, double-sided tape, and as an anti-slip film.

October 25, 2023

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing