Industry Leaders Partner to Reduce Emissions in Adhesive Products

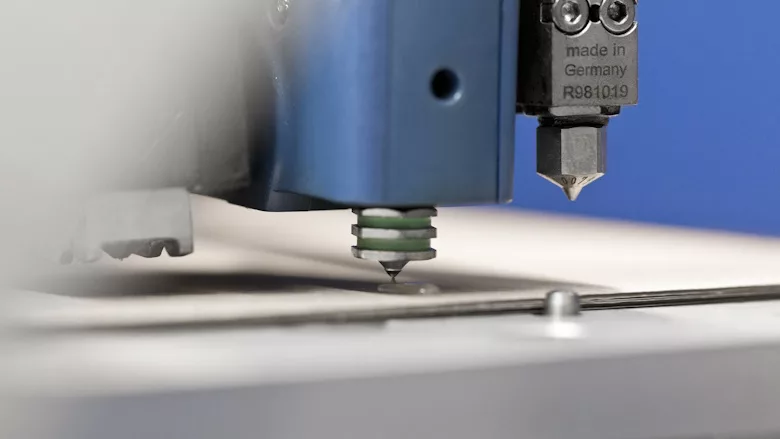

Image courtesy of Henkel.

Henkel Adhesive Technologies, Kraton Corp., and Dow Inc. have achieved a reduction in product carbon footprint for two of Henkel's North American flagship products for end-of-line packaging. The products are TECHNOMELT® SUPRA 100 and TECHNOMELT® SUPRA 106M.

The TECHNOMELT SUPRA 100 LE and TECHNOMELT SUPRA 106M LE formulas are designed with biobased alternatives that reduce the adhesives' cradle-to-gate carbon footprint by 25%1 compared to the legacy products. This reduced footprint is enabled by a proprietary formulation of Kraton's SYLVALITE™ 2200 biobased tackifiers developed with REvolution™ rosin ester technology and Dow's AFFINITY™ GA polyolefin elastomers. The lower emission formulations maintain equivalent performance and food-safe properties customers expect from the legacy designs.

"At Kraton, we understand the importance of sustainability in today's adhesive and packaging markets," said Minco van Breevoort, Kraton Pine Chemicals president. "Supplying Henkel with our REvolution technology and biobased tackifiers reflects our long-standing dedication to innovating solutions that satisfy customer needs and reduce environmental impact. We take pride in driving the transition towards sustainable adhesive and packaging solutions."

Sustainable products often carry a premium price due to higher manufacturing costs and increased regulatory pressure for Scope 1, 2 and 3 greenhouse gas emissions reporting. By investing in lower carbon emission formulations, Henkel, Kraton and Dow are meeting consumer demand for sustainable packaging and making these solutions more attainable for consumer goods manufacturers. As a result of the combined investment, TECHNOMELT SUPRA 100 LE and TECHNOMELT SUPRA 106M LE will be available to existing customers at no additional cost2.

"Henkel has been leading the efforts on sustainable solutions which promote emission reduction, circularity and safety. Sustainability is not just our responsibility to future generations but integral to our long-term success as a company," explained Ulla Hüppe, head of sustainability for Adhesive Technologies at Henkel. "By working with Kraton and Dow, we are able to offer lower emission solutions and establish new industry precedence."

"We believe in the power of collaboration with like-minded companies who share Dow's values and ambition. With Henkel and Kraton, we're not just forging collaborations, we're creating a sustainable ecosystem. We're proud to be setting a precedent of working together with other industry leaders to drive change and bring value to customers," said Haley Lowry, global director sustainability, Dow.

Kraton's REvolution is an innovative technology platform designed to deliver enhanced color performance and oxidative stability in biobased tackifiers such as Kraton's SYLVALITE 2200. The technology provides a sustainable alternative to fossil-based products, enabling formulators to achieve a high biobased content and a low carbon footprint. Dow's AFFINITY GA offers advanced performance for extreme temperatures in packaging. The TECHNOMELT product portfolio includes other biobased formulations, as well as innovative low-temperature, hot-melt adhesive formulations.

Learn more about Henkel www.henkel.com. Additional information about Kraton Corp. is available at www.kraton.com. To learn more about Dow, visit www.dow.com.

1. Carbon footprint calculation estimated cradle-to-gate from Henkel's internal LCA assessment, excluding emissions in the use phase and end of life. Due to accounting for biogenic CO2 uptake and other net biogenic emissions in constituents of Henkel’s adhesive, shown CO2 impact can be used only on product level, not on corporate level. Further details are required to derive resp. claims for customer-specific reporting.

2. Cost fluctuations may arise as an effect of prevailing market conditions and the interplay of supply and demand factors to which may change the price.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!