EVONIK: Heat-Stable Hardener

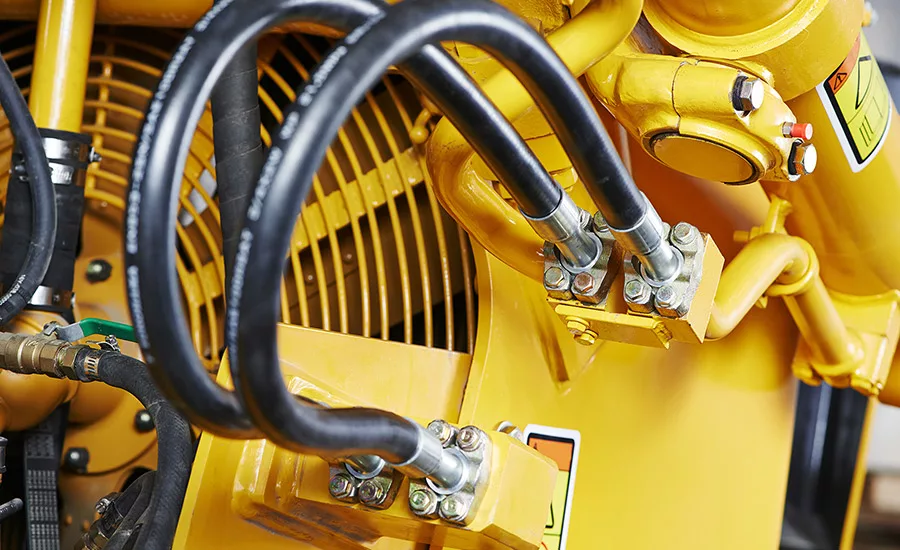

TEGO Cure 100 was specially developed for surfaces that are continuously exposed to high temperatures, such as ovens, pipes, or machines that become hot during operation. (Image courtesy of Evonik.)

The new TEGO® Cure 100 hardener from Evonik reportedly ensures that coatings cure at room temperature, eliminating the need for costly and energy-intensive drying in the oven. At the same time, the surface is heat-stable up to 650°C during application.

TEGO Cure 100 was specially developed for surfaces that are continuously exposed to high temperatures, such as ovens, pipes, or machines that become hot during operation. The hardener is suitable for silicone resins, as well as silicone combination resins, and offers a range of additional advantages. For example, the hardener improves the corrosion protection of the coating, especially when it is under an insulating layer. In addition, the high solids content of more than 99% reduces solvent emissions to a minimum.

“Our new hardener meets the ever-increasing regulatory requirements,” said Maximilian Morin, head of the Industrial & Transportation Coatings market segment. “We are convinced that the new hardener will be a future-proof component in our customers’ formulations.”

The new silicone resin-based hardener is particularly suitable for direct-to-metal coatings, allowing costly multi-layer buildups to be avoided. Due to its high resistance to corrosion, chemicals, and weathering, even single-layer systems offer high surface protection.

Evonik reports that TEGO Cure 100 is easy to handle. Even though it is a highly reactive hardener, it has a wide processing window and is also stable in storage over a very long period.

Additional details are available at www.coating-additives.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!