SCHEUGENPFLUG: Dispensing Inspection System

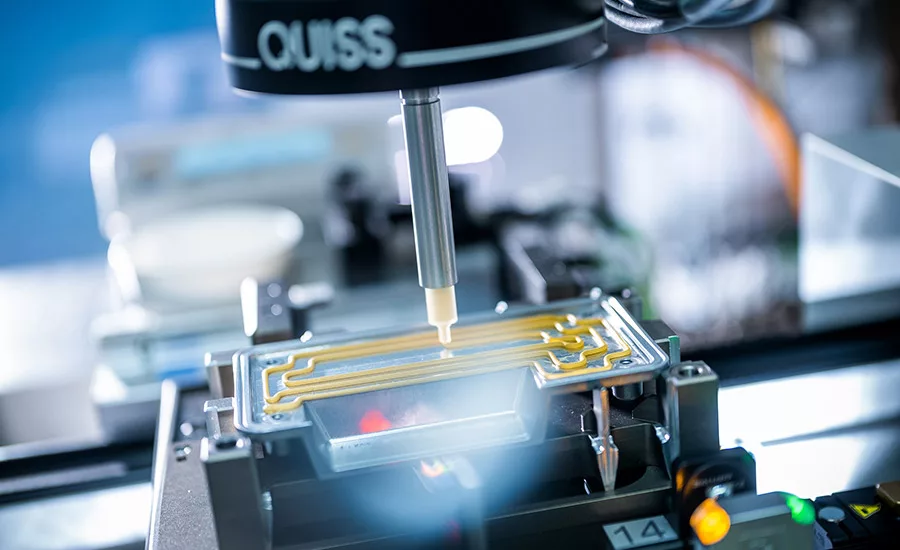

With inspection integrated in the dispensing cell, applying adhesives and sealants goes hand in hand with quality assurance. (Image courtesy of Scheugenpflug GmbH.)

Scheugenpflug recently announced that it has added an inspection system to its portfolio, making quality monitoring an integral part of the dispensing cell to save time and space. By integrating RTVision systems, Scheugenpflug has expanded its portfolio for automated production lines handling adhesive and sealant dispensing tasks.

To ensure optimum proven and traceable product quality, vision systems are used to check the width, position, and uninterrupted application of the adhesive or sealant during application. Since the quality of application is known as soon as the adhesive or sealant has been applied, there is no need for a separate cell; this saves on cycle time and resources. Operators benefit from significant cost and time savings, as well as from documentation and traceability even years after each individual component has been delivered.

Scheugenpflug reports that it is adhering to its philosophy of offering everything from a single source and equipping its system solutions with 2D and 3D inline inspection systems from Quiss. These image processing systems allow the production plants to “see.” They visually check and monitor the application of adhesives and sealants. The sensors are mounted directly on the application head above the nozzle.

The RTVision version with 2D sensors uses an LED light source as the incident light to detect the width and continuity of the application by contrasting the adhesive bead with the background. RTVision 3D uses six lasers as the light sources to evaluate the third dimension (height), as well.

Users reportedly benefit from the user-friendly software because the parameters are easy to set and the software indicates a clear OK/NOK. Detailed visualization means that the status is instantly visible, and any discrepancies can be immediately and easily assigned. Teach-in functionalities support the plant personnel and shorten the commissioning time, while robust, industry-proven algorithms ensure smooth 24/7 operation.

For more information, visit www.scheugenpflug-dispensing.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!