Renewable, Cashew Nutshell Liquid-Based Polyols: Their Benefits in CASE and Polyurethane Foams

Evaluating the performance and key characteristics of CNSL-based polyols in the formulation of various PU systems, including protective coatings, adhesives, and foams.

Image courtesy of quangpraha / iStock / Getty Images Plus via Getty Images.

Polyurethanes (PU) have been extensively used in a broad range of industrial applications, such as foams, textiles, composites, adhesives, sealants, and coatings. For example, the polyurethane demand worldwide in 2017 was about 16.9 million tons, and it is forecasted to grow close to 22.5 million tons by 20241. In the CASE applications, polyurethane chemistry has become more and more attractive because of its valued properties of superb durability and toughness, excellent abrasion resistance, adhesion strength on various substrates, as well as desired aesthetic finishes2. Most of the polyols currently used in polyurethane applications such as foams, coatings, adhesives, and elastomers, derive from petroleum-based feedstock, but the growing interest in materials from renewable sources has led to the development of several bio-based polyols3. There are no significant examples at industrial scale of bio-based polyols with an aromatic backbone, as the majority of bio-based materials currently available are soybean-, palm-, or castor oil-based, which can offer hydrophobicity and good flexibility but lack chemical and thermal performances. The structures and properties of polyols or isocyanates as raw materials can significantly affect the physical, mechanical, and chemical properties of the final polyurethane systems. Therefore, the proper design and modification to the raw materials, especially polyols, is an effective way to enhance the performances of polyurethane systems to meet requirements for various applications.

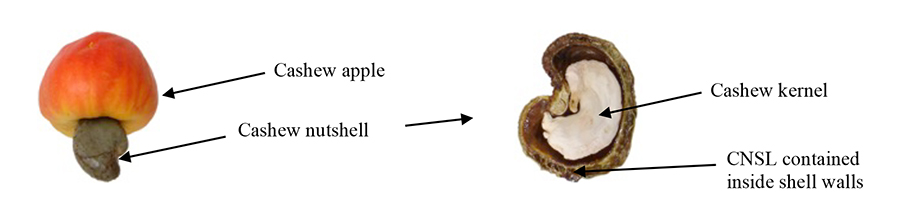

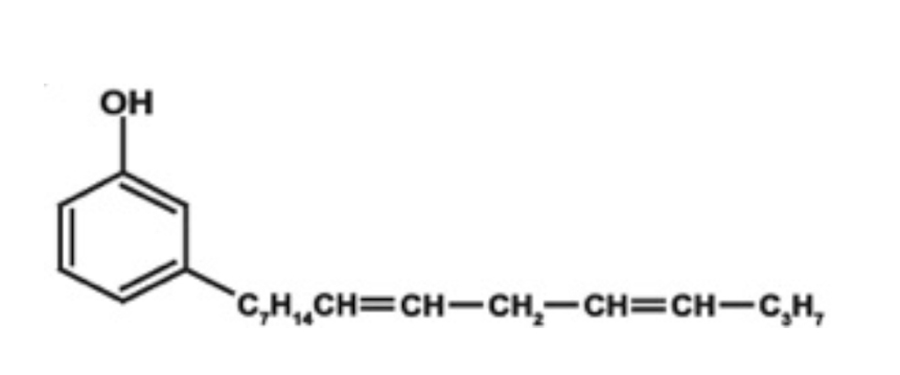

Cashew Nutshell Liquid (CNSL) is a sustainable and non-food-chain biomaterial that is contained in the honeycomb structure of the cashew nutshell4,5. Shown in Figure 1, cardanol is the main component derived from CNSL via decarboxylation and distillation. Cardanol (average structure illustrated in Figure 2) is a penta-decadienyl phenol with a long aliphatic side chain that consists of a mixture of one, two, and three double bonds in a linear chain. Such unique and versatile structure enables this natural oil to become a very important chemical building block for numerous bio-based products including polyols.

*Click the image for greater detail

Figure 1: Cashew Apple and Nutshell.

Cardolite has developed a series of solvent-free and low-viscosity bio-based polyols, which are successfully used in various applications such as PU foams6 and adhesives7. Those new bio-based polyols are mainly based on CNSL technology, except for a few polyols. The CNSL-based polyols exhibited distinctive properties inherited from the cardanol structure such as good chemical resistance and fire resistance8 due to the aromatic ring, and excellent hydrophobicity7,8 due to the presence of the long aliphatic side chain. To achieve color stability and maintain good mechanical properties, non-CNSL renewable polyols were also developed.

*Click the image for greater detail

Figure 2: Cardanol’s average structure.

This paper will discuss performances of each polyol and its key characteristics that help to achieve un-met needs in protective coatings, adhesives, and PU foams. For coatings, performances of PU protective coatings and pipeline coatings including adhesion to metal substrates, abrasion resistance, corrosion protection as well as cathodic disbonding resistance will be presented. In terms of the benefits of Cardolite polyols for adhesives and sealants, excellent bond strength on various substrates, i.e., metals, plastics, composite, and good hydrolytic stability are key discussion points. Concerning foam applications, the paper will focus on rigid foams and share reactivity, thermal, and fire performances of polyols in PU foams.

Materials and Experiments

Table 1 presents the typical physical properties and bio-content of Cardolite bio-based polyols. These polyols are selected based on their quality control properties and unique values to selected PU applications. For coatings, NX-9001, LITE 9001, NX-9008, and NX-9014 were evaluated in two PU coating formulations. In the adhesives study, NX-9005, NX-9008, and NX-9018 were evaluated for their contributions to improve unmet properties in PU systems. NX-9001, NX-9008, and NX-9018 were also used in rigid foam formulations to understand their performances and demonstrate their versatility as raw materials in cellular polyurethanes. At the same time, NX-9101 was tested as self-catalytic polyol, benchmarking versus petro-based Mannich.

Viscosity, hydroxyl value, acid value, and water content measurements on the different polyols were performed according to ASTM D4878, ASTM D4274, ASTM D4662, and ASTM D4672, respectively.

GPC analysis for cardanol-based polyols molecular weight characterization and functionality determination was performed on the same HITACHI HPLC-GPC systems, isocratic mode (0.5 ml/min flow rate; wavelength set to 280 nm). Three columns connected in series (Tosoh TSKgel Super H1000, Tosoh TSKgel Super H2000, Tosoh TSKgel Super H3000, 3 μm, 6x150 mm; mobile phase: tetrahydrofuran) or a single column (Tosoh TSKgel G3000, 5 μm, 7.8x330 mm; tetrahydrofuran, buffered with 0.25% TFA and 0.25% TEA) thermostated at 40 °C were used. 11 narrow MW polystyrene standards have been used for the calibration curve.

.jpg)

*Click the image for greater detail

Table 1: Typical properties of Cardolite polyols and selected reference.

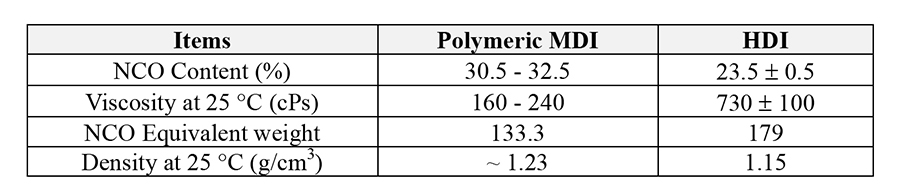

Commercially available polyols, surfactants, catalysts, and blowing agents were used in the foaming trials. Two types of isocyanates (Table 2) were used as crosslinkers: MDI-based polyisocyanate, referred to as polymeric MDI (pMDI), and hexamethylene-1,6-diisocyanate, referred to as HDI.

*Click the image for greater detail

Table 2: Typical properties of isocyanates used in the present study.

Test specimens and results are obtained based on the following ASTM methods: Lap shear strength (ASTM D1002) on sandblasted steel, tensile strength/elongation (ASTM D638), Mandrel bend (ASTM D522), direct and reverse impact (ASTM D2794), crosshatch adhesion (ASTM D3359), chemical resistance (ASTM D6943), and shore D/A hardness (ASTM D2240). Cathodic disbonding (CD) was carried out according to ISO 15711-method A. Gel time was measured in 50 grams amounts at 25 °C by using a gel time meter. Linear dry time tests were conducted using an 8-mil wet film thickness drawn down bar according to ASTM D5895-03. Moisture sensitivity of polyols was determined by measuring the amount of CO2 generated after pouring pre-mixed polyurethane into water and keeping resulting blends at room temperature for 24 h (it is in fact known that isocyanates react with water to generate CO2 gas, and therefore, the greater the hydrophobicity the lower the CO2 evolution).

Foam specimens were stored at room temperature for 48 h prior to testing. Density and reactivity, compression strength, water absorption, were measured accordingly to ASTM D7487, ASTM D1621, and ASTM D2842, respectively. Fire tests were determined accordingly to vertical UL-94.

Results and Discussion

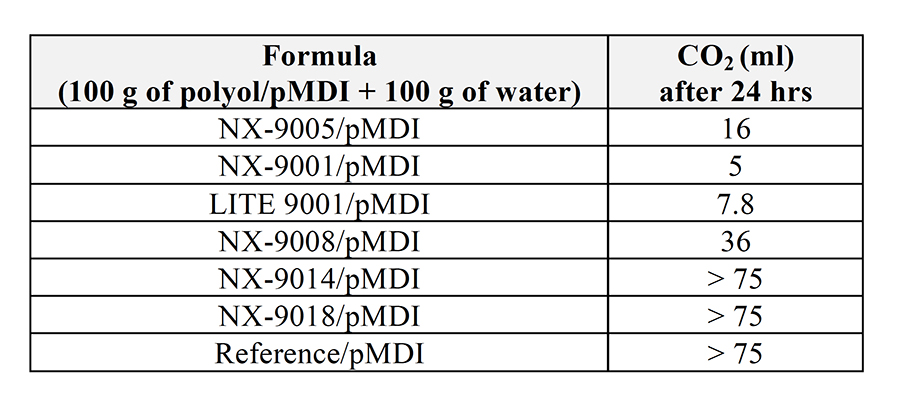

Polyurethanes use isocyanates that are moisture sensitive, and the absorbed moisture can induce an unwanted side reaction like generation of CO2 bubbles. Polyols with excellent hydrophobicity will reduce moisture sensitivity during the blending process of isocyanates and polyols, which leads to lower CO2 evolution and ultimately extends the service life of the adhesive by preventing failure from hydrolysis. The polyols that are intended to be used in coatings and adhesives have been tested in 2K polyurethane systems using a standard-grade polymeric MDI and compared to a reference castor oil-based polyol characterized by comparable OH value, measuring carbon dioxide evolved after blending 100g of polyurethane premix and 100g of water. As evident from the data reported in Table 3, the amount of CO2 formed in the NX-9001 and LITE 9001 systems is much lower than in the standard hydrophobic castor oil reference system, indicating superior hydrophobicity of NX-9001 and LITE 9001 followed by NX-9005 and NX-9008.

*Click the image for greater detail

Table 3: Moisture sensitivity study by CO2 evolution test.

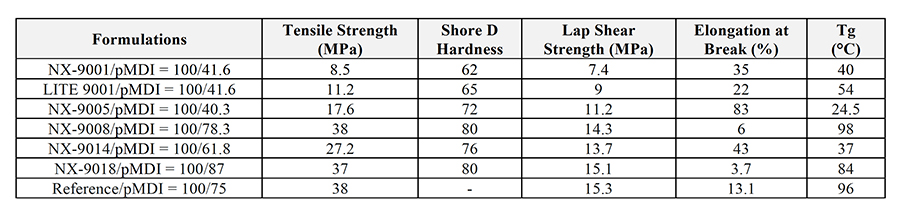

Basic mechanical properties and Tg data are displayed in Table 4. Cure conditions are varied to achieve full cure of the systems. NX-9001, LITE 9001, NX-9005, and NX-9008 are cured for 7 days at room temperature while NX-9014, NX-9018, and the reference were prepared at 70 °C/4 hrs + 120 °C/2.5 hrs. NX-9005 has the most well-balanced strength and flexibility, while NX-9008 and NX-9018 can offer very high tensile strength and bond strength along with high Tg, with similar properties of an epoxy system. NX-9014 will be featured for its good color stability in PU systems as well as its balanced tensile strength and elongation.

*Click the image for greater detail

Table 4: Mechanical properties of polyols with pMDI (Index 100).

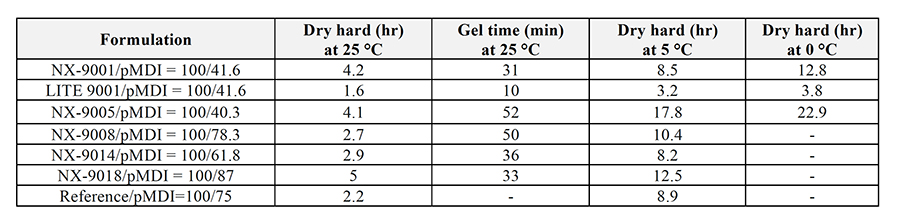

Gel time and linear dry times at various temperatures (25 °C, 5 °C, 0 °C) are shown in Table 5. LITE 9001 is the fastest polyol to cure while the rest of the polyols can also achieve reasonable cure speeds at 25 °C and 5 °C with good pot life.

*Click the image for greater detail

Table 5: Cure speed (dry times, gel times).

1. Study of PU Coatings

1a. Performance study in low-V.O.C 2K PU protective coatings

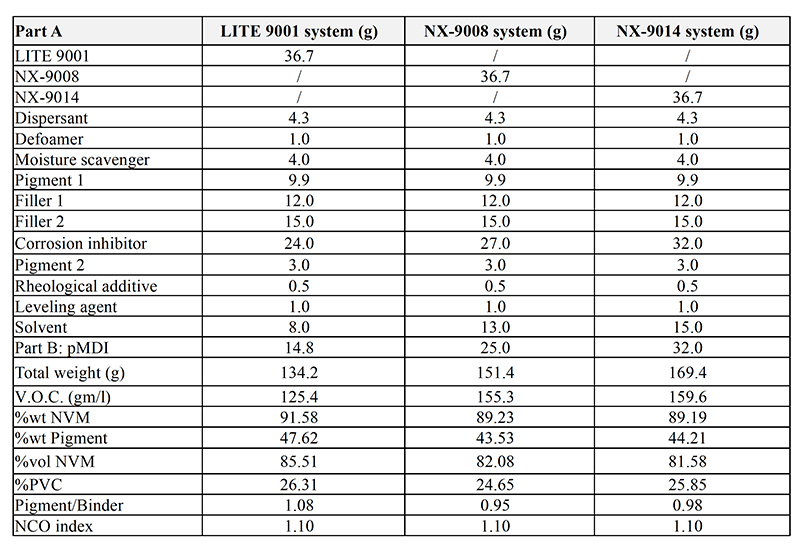

Three 2K low-VOC. PU protective coating systems (Table 6) were formulated for air spray application based on LITE 9001, NX-9008, and NX-9014. When combined with polymeric MDI at a 110 NCO index, these three formulations can reach 90% solids by weight with final calculated VOC values of 125.4 g/L, 155.3 g/L, and 159.6 g/L for LITE 9001, NX-9008, and NX-9014 systems, respectively. The three formulations contained about 37-43% inhibitor pigments in total pigment weight and used no catalysts to speed up cure properties.

*Click the image for greater detail

Table 6: 2K PU protective formulations.

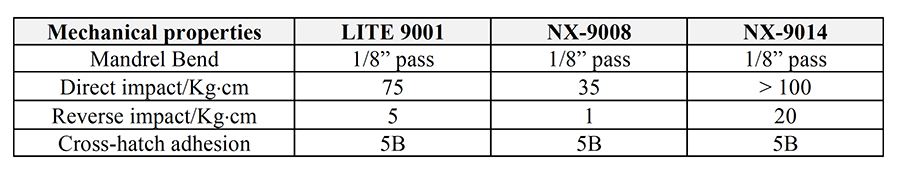

All test panels were prepared over cold-roll steel substrate by drawing down films of 6 mils wet film thickness; after panels cured at RT for 7 days, Mandrel Bend, impact resistance, and cross-hatch adhesion tests were conducted.

*Click the image for greater detail

Table 7: Flexibility and adhesion properties of three PU protective coatings.

Results demonstrate that all three PU coatings exhibited very good Mandrel Bend performance, with the NX-9014 system showing much higher impact resistance than the other systems due to its branched aliphatic structure. Moreover, it can be observed that the NX-9008 system was less flexible in comparison to LITE 9001 and NX-9014, which might relate to its high crosslinking density. Furthermore, one of the big challenges for PU systems is good adhesion to metal substrates. Crosshatch adhesion test results shown in Table 7 suggest that these three new bio-based polyols could provide excellent adhesion to cold-roll steel that could help achieve excellent anti-corrosion performance.

Traditional protective coatings usually consist of an epoxy primer and a PU topcoat to provide the best synergistic performances. For example, the epoxy primer offers excellent adhesion to the metal substrate as well as good barrier property while the PU topcoat delivers toughness and excellent weatherability. However, when a PU coating system is used as a direct-to-metal (DTM) system without an epoxy primer, the long-term corrosion protection becomes a challenge.

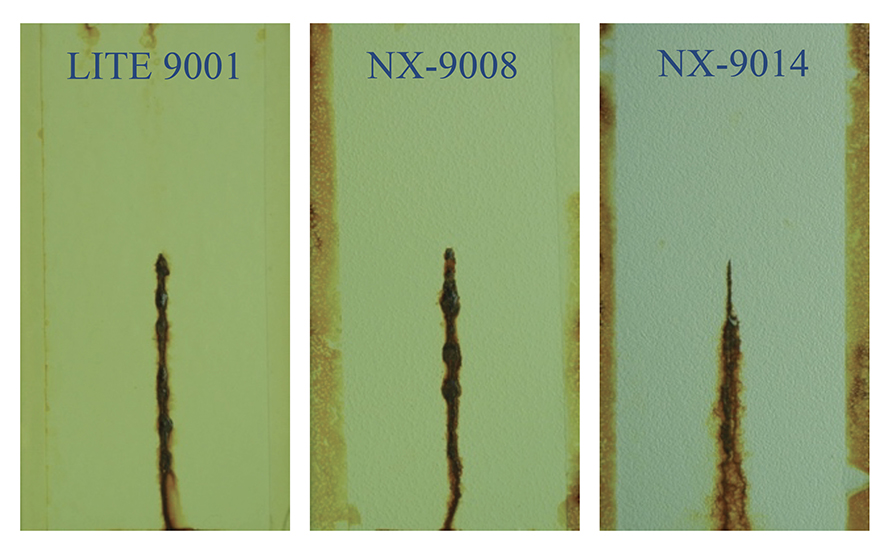

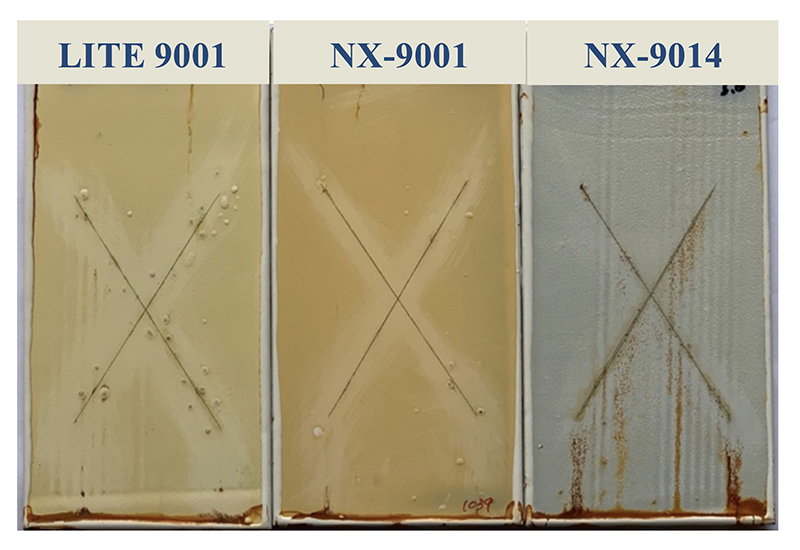

In this study, the anti-corrosion performance of LITE 9001, NX-9008, and NX-9014 systems was evaluated by salt spray exposure in a Q-FOG tester chamber (Model SSP600) according to ASTM B117. These three PU coating systems were air sprayed over cold-roll steel substrates (QD-36) to a final dry film thickness of around 90 microns after a 7-day RT cure. After 800 hours of exposure, different performance aspects, such as rust, blisters on field, and creep along the scribe line were checked. The photo images of testing panels after salt spray exposure are shown in Figure 3. It can be seen that there were no blisters or rust on panel fields; the maximum creep width was 1.5 mm, 2 mm, and 2 mm for the LITE 9001, NX-9008, and NX-9014 systems, respectively. The salt spray test results suggest that the LITE 9001, NX-9008, and NX-9014 systems could provide very good barrier protection without any blister and delamination issues; the low creep width indicated that the three PU systems could offer good adhesion to metal substrates. Moreover, these results confirm the hydrophobicity derived from CNSL could benefit LITE 9001 and NX-9008 coating systems. The NX-9014 system could also achieve good anti-corrosion performance through its branched structure combined with a little higher inhibitor pigment loading.

*Click the image for greater detail

Figure 3: Testing panel image after 800 hours salt spray exposure.

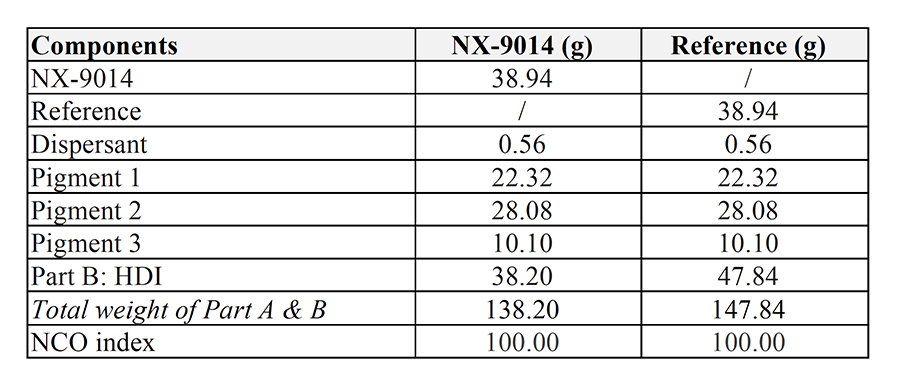

It is usually expected and desirable that PU systems provide excellent UV and weathering stability. As with many natural products, CNSL-based polyols LITE 9001 and NX-9008 tend to not show very good UV resistance. However, NX-9014 was designed for good UV stability while balancing bio-content. In this study, the color stability of NX-9014 was compared to a reference polyol in the formulation in Table 8 using aliphatic HDI. The reference selected as benchmark is considered one of the best polyether/polyester polyols in terms of UV stability.

*Click the image for greater detail

Table 8: Color stability formula.

Based on the test results shown in Figure 4, it is evident that the NX-9014 system exhibited very good UV resistance, similar to the reference system. The excellent color stability of the NX-9014 system suggests it could be a very good PU topcoat system in addition to a good DTM protective coating.

*Click the image for greater detail

Figure 4: Color stability of three PU systems after QUV A exposure.

1b. Performance study in SF 2K PU pipeline coating systems

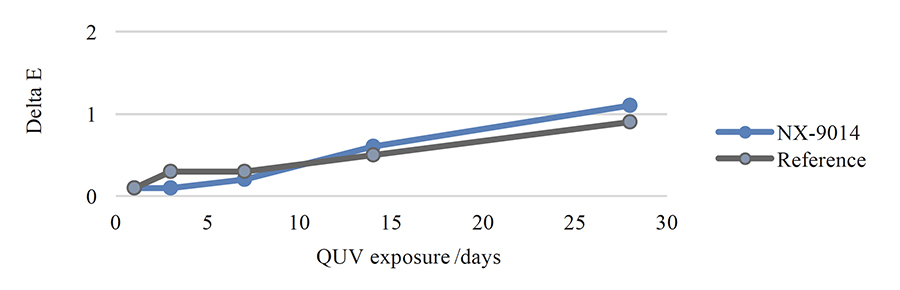

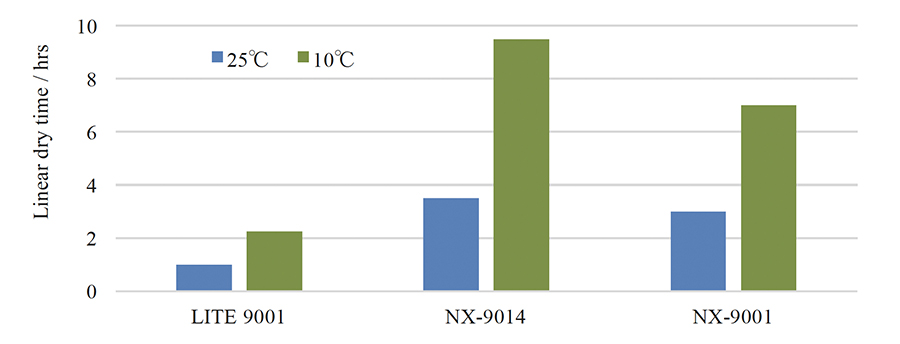

In recent years, the use of polyurethane systems as protective coatings for pipeline applications has increased due to their excellent mechanical performance and good weathering resistance. In this study, LITE 9001, NX-9014, and NX-9001 were formulated as solvent-free 2K PU pipeline coating systems (Table 9), using polymeric MDI (Index 110) and without the addition of any catalyst.

*Click the image for greater detail

Table 9: 2K SF PU pipeline coating formulations.

These formulations did not use solvents; the final VOC for the LITE 9001, NX-9014, and NX-9001 systems were 8.69 g/L, 7.42 g/L, and 8.46 g/L, respectively, which mainly came from the volatile components in additives. In addition, the three PU pipeline coatings did not contain any corrosion inhibitor pigments; and they had final PVC around 10-11%, which suggested that the barrier protections mainly relied on the PU binder systems.

*Click the image for greater detail

Figure 5: Cure properties of three PU pipeline coating systems at two different cure conditions.

Pipeline coatings are usually applied and cured on-site, therefore, fast cure speed especially at low temperatures is requested to widen the application window to year-round. The linear dry time data shown in Figure 5 suggests that the LITE 9001, NX-9014, and NX-9001 systems could provide good cure properties. For example, the LITE 9001 system showed dry hard times of 1 hour and 2.25 hours at 25 °C and 10 °C cure conditions, respectively, while the NX-9014 and NX-9001 systems were not as fast as the LITE 9001 system, but still achieved dry hard times of less than 3.5 hours and 10 hours at 25 °C and 10 °C cure conditions, respectively. Since no solvents and catalysts were used in these three pipeline coatings, it can be concluded that the high reactivity of CNSL-based polyols was a major contributor to the fast cure properties of the final PU systems.

*Click the image for greater detail

Table 10: Flexibility and adhesion property of three PU protective coatings.

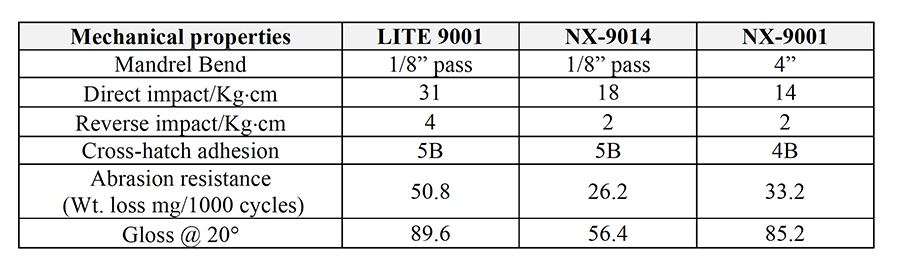

In this study, the mechanical properties of three SF PU pipeline coatings were tested over cold roll steel substrate with a wet film thickness of 6 mils. After a 7-day cure at RT, Mandrel Bend, impact resistance, abrasion resistance, and crosshatch adhesion tests were conducted. According to the results reported in Table 10, it can be observed that the LITE 9001 and NX-9014 systems exhibited good Mandrel bend performance, while the NX-9001 system was less flexible. The three SF PU pipeline coating systems showed excellent adhesion to cold-roll steel substrate and achieved very good abrasion resistance properties as indicated by their weight losses after 1000 cycles of 50.8 mg, 26.2 mg, and 33.2 mg for LITE 9001, NX-9014, and NX-9001, respectively. It is also noticeable that the coating films based on LITE 9001 and NX-9001 displayed higher gloss than that of the NX-9014-based coating, which might be due to the lower moisture sensitivity of CNSL-based polyols during the cure process.

*Click the image for greater detail

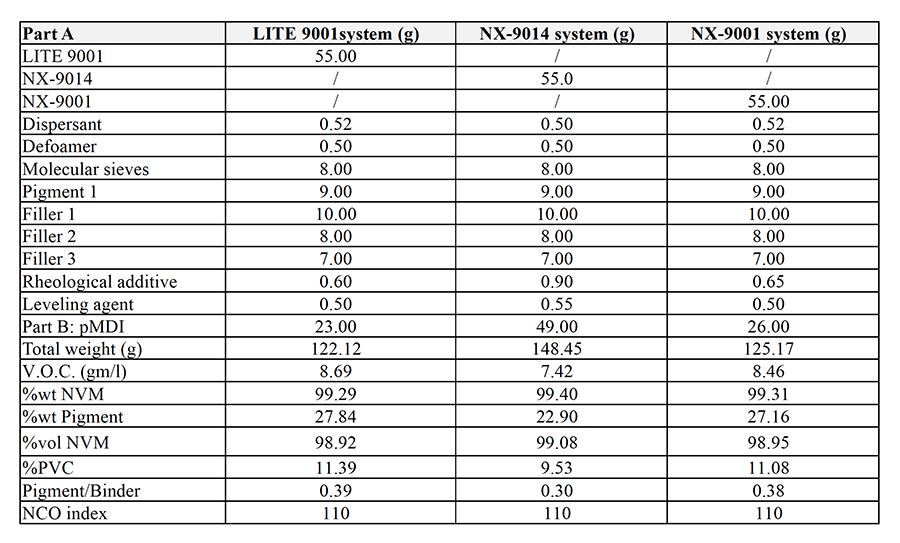

Figure 6: Panel images of SF PU pipeline coating systems based on LITE 9001, NX-9001 and NX-9014, respectively, after 1039 hours of salt spray exposure (SA2.5 sand blasted steel substrate, RT cure, DFT » 5 mils).

As an additional part of the same study, the anti-corrosion performance of each of the SF PU pipeline coatings was evaluated. The three PU pipeline paint systems were applied over sandblasted steel (SA2.5) via No. 60 RDS lab rod, with a final dry film thickness of about 5 mils after 7 days RT cure. Figure 6 displays the test panel images after 1039 hours of salt spray exposure. Most surface rust stains were removed via slight sanding with 800 grit sandpaper to reveal the details of blisters and creeps. It can be seen that there was almost no creep developed along the scribe line on any of the three PU systems. The LITE 9001 system had more blisters than the NX-9014 and NX-9001 ones, but mainly congregated along the scribe line. The NX-9014 system had almost no blisters, while the NX-9001 system showed some blisters. As noted earlier, no corrosion inhibitor pigments were added in the formulations, thus the corrosion protection of these coatings came from the barrier properties provided by the polyol-isocyanate network. Moreover, test results suggested that both NX-9014 and NX-9001 systems offered better barrier protection than the LITE 9001 system.

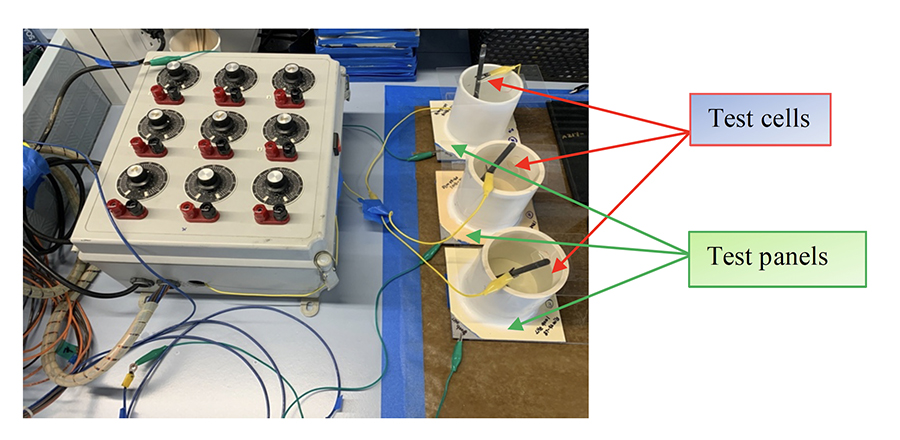

For underground pipelines and tanks or buried metal constructions, the major part of the corrosion protection comes from cathodic protection in which the metal substrate becomes the cathode via two methods: one is to connect external anodes to metal substrates; another is to impress necessary currents through external anodes by using a DC power source. In general, the method of applying impressed current systems is more commonly used to protect underground pipelines and tanks due to its better suitability for large size structures and its lower susceptibility to ground environments. Since it is difficult to prevent pipelines from experiencing excessive current at times, coating systems for buried metal constructions should withstand cathodic disbondment besides providing excellent barrier protection to limit the penetrations of moisture, ions, and oxygen to the metal surface.

*Click the image for greater detail

Figure 7: Setup of cathodic dis-bonding test.

Cathodic disbonding (CD) testing for three SF PU pipeline coatings were carried out according to ISO 15711- method A. The test panels were prepared by brushing the PU paints over sand blasted steel panels to obtain thick coating films. The NX-9014 and NX-9001 systems had dry film thickness of 66 mils and 62 mils, respectively; the LITE 9001 system had a higher film thickness of 87 mils due to its fast viscosity build-up. After 10 days cured at RT, each test panel was drilled to get a Ø 5 mm artificial hole in the center of the panel and glued to an Ø 8 cm plastic tube as the test tank, which was filled with fresh artificial seawater solution. The CD test setup used in this study is shown in Figure 7: graphite electrode was used as anode, copper/copper sulfate electrode was used as reference electrode, and a galvanostat was used to control the test potential.

Figure 8 displayed the panel images of the three SF PU pipeline coating systems after 42 days cathodic disbonding test at RT. It can be seen that the maximum disbonding distances from the artificial holes were 3 mm, 3 mm, and 8 mm for the LITE 9001, NX-9014, and NX-9001 systems, respectively. Furthermore, there were no blisters or rust observed on these three tested PU coatings. The test results suggested that the SF PU coatings based on LITE 9001 and NX-9014 could provide excellent cathodic disbondment resistance. Though not as good as the other systems, the NX-9001 system still showed good cathodic disbondment resistance and could potentially show improved performance in more flexible formulations that compensate for the lower flexibility of NX-9001.

*Click the image for greater detail

Figure 8: Panel images of SF PU pipeline coating systems based on LITE 9001, NX-9001 and NX-9014, respectively, after 42 days RT cathodic disbonding test (SA2.5 sand blasted steel substrate, 10 days RT cure, DFT » 60-80 mils).

2. Study of PU Adhesives

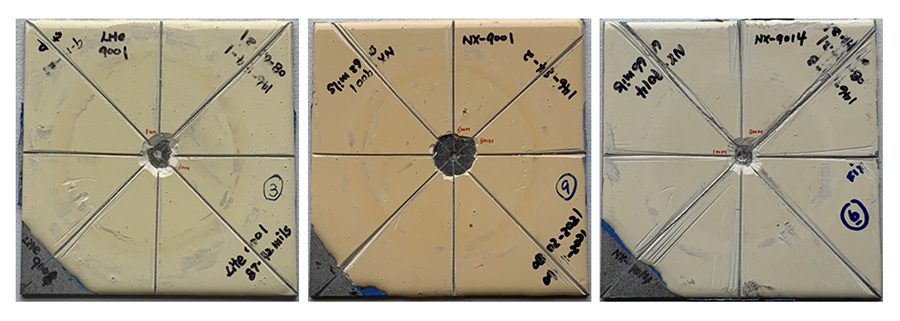

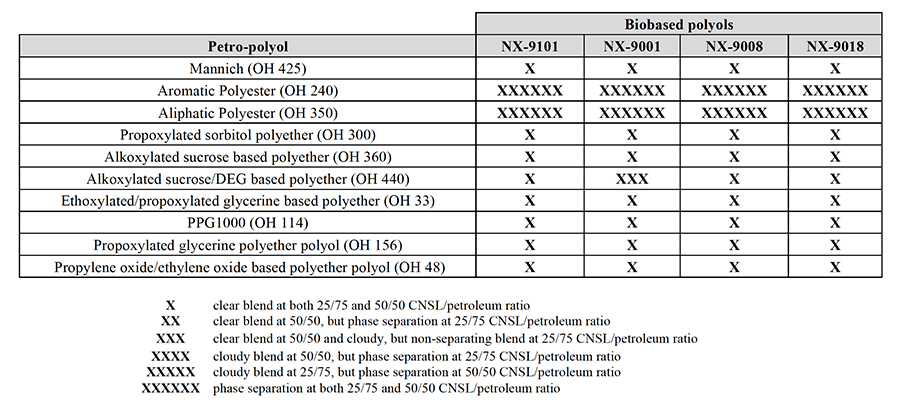

Table 4 shared the cohesive strength, flexibility, and Tg of PU systems based on Cardolite’s polyols. It is known that good bond strengths can be achieved when the resin systems offer high strength, reasonable flexibility, and good wetting of the substrates. Substrates that are inherently flexible like plastics tend to have good adhesion strength with systems that have good flexibility and good wetting on low-surface-energy substrates, typical characteristics of plastics. Therefore, using PU adhesives especially with NX-9005 is a suitable option for plastics bonding. For metals and composite substrates (carbon fiber reinforced epoxy prepreg), polyols with high tensile strength i.e., NX-9008 and NX-9018, have exhibited higher lap shear (Table 11). All the polyols were tested under the same conditions and cured for 40 °C/16 hr. Metal substrates were sand blasted and alcohol wiped, while plastics and composite substrates were sand paper abraded and alcohol wiped prior to the application of the adhesive.

*Click the image for greater detail

Table 11: Lap shear strength on metals, plastics and composite substrates.

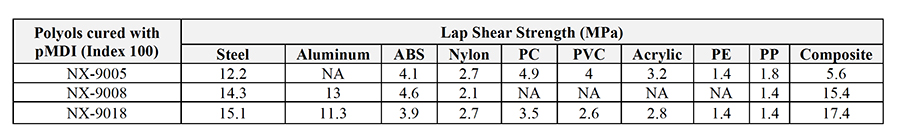

Hydrolysis of polyurethane adhesives upon exposure to water can result in reduction on adhesive strength and loss of durability. In addition to previous comments (Table 3) on polyols’ moisture sensitivity and effect of hydrophobicity, Table 12 shows a change of lap shear strength upon exposure to 80 °C water for 7 days. As expected, polyols with low moisture sensitivity like NX-9001 and NX-9005 have demonstrated the lowest loss of adhesion, due to their excellent hydrophobicity.

*Click the image for greater detail

Table 12: Hydrolytic stability using change of lap shear after 80 °C/7 dd water immersion.

3. Study of PU Foams

In order to evaluate their versatility and assess their potential applicability in different type of polyurethane systems, some of the grades previously described (NX-9001, NX-9008, and NX-9018) have been tested in rigid polyurethane foams characterized by different reactivity: continuous panels and spray systems. At the same time, NX-9101, a low-viscosity cardanol-based Mannich polyol has been selected as a suitable candidate to be included in the spray foam study, benchmarking versus a petro-based Mannich polyol characterized by comparable hydroxyl value.

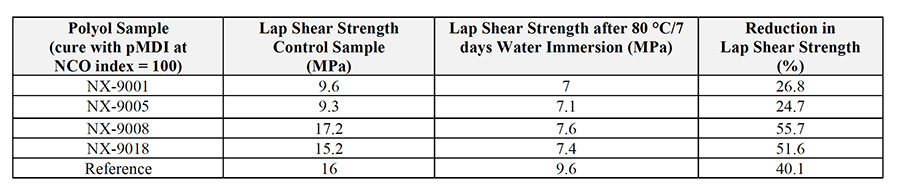

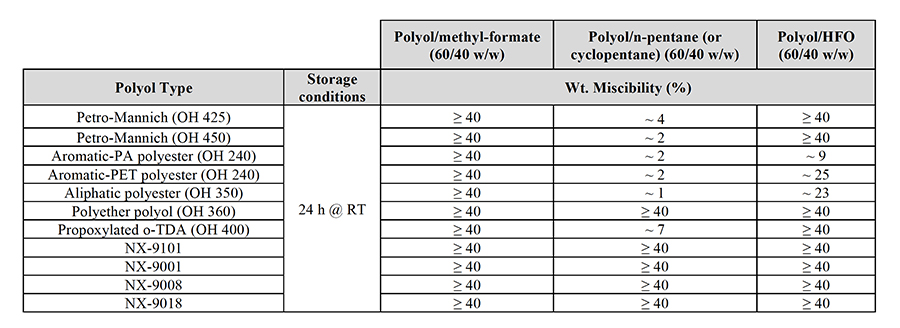

As a very first step of the study, the compatibility of the selected candidates and standard petro-based polyols have been verified (Table 13). Several blends (based on combinations of CNSL polyols, petro-based Mannich polyols, aliphatic and aromatic polyester polyols, and polyether polyols) have been prepared and monitored for their stability.

*Click the image for greater detail

Table 13: CNSL-polyols and petro-polyols compatibility.

CNSL-based polyols, even if characterized by a high hydrocarbon content, contain enough polar groups (amino, hydroxyl, esters) to guarantee an excellent compatibility with polyether polyols and petro-based Mannichs. On the contrary, as in the case of other NOPs based polyols9, CNSL-polyols show limited miscibility with polyester polyols (both aliphatic and aromatic). However, this limitation can be easily overcome by properly tuning the composition of the B-part of the PU formula, as for example, using a polyether polyol as a co-polyol, balancing the CNSL-polyol/polyester polyol ratio, or using non-ionic surfactants, emulsifiers or blowing agents with a solvent effect (e.g. methyl formate).

*Click the image for greater detail

Table 14: Biobased polyols and petro-based polyols miscibility with standard blowing agents.

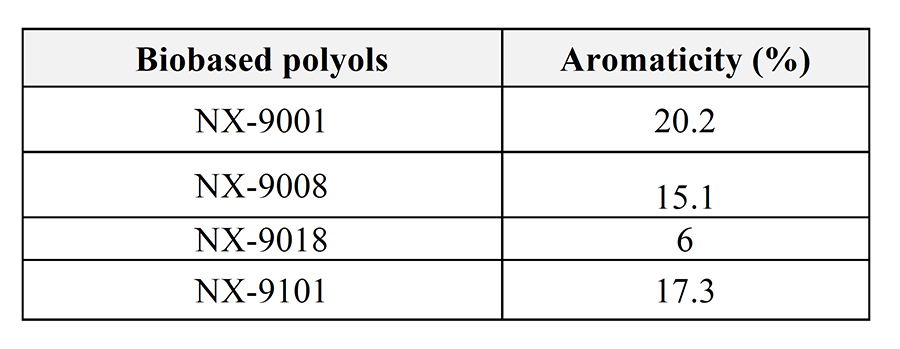

A different aspect that has also been verified is the compatibility of CNSL polyols with standard blowing agents for spray and PIR polyurethane foams (e.g. n-pentane, methyl-formate, HFC, and HFO), as it is a key aspect to guarantee final foam properties and B-part stability. This miscibility study has been accomplished by blending polyols (both CNSL- and petro-based) and blowing agents (60/40 w/w) in tightly closed graduated containers, and recording the appearance of the mixtures after 24 hours at room temperature. In case of phase separation, the miscibility has been determined by measuring the height of the blowing agent phase: since the density is known, the amount (in grams) of the blowing agent dissolved into the polyol-phase can be easily recovered (Table 14). NX-9101, NX-9011, NX-9008, and NX-9018 show excellent miscibility with methyl-formate, n-pentane (same results are obtained with cyclopentane), and HFO (Opteon 1100), better than petro-derived Mannich polyols and polyester polyols (both aromatic and aliphatic ones).

Considering cardanol-based polyols’ chemical structure and the contribution of polyols’ aromaticity to PU foams fire performances, the aromatic content of Cardolite bio-based polyols has been calculated (Table 15), with results being close to aromatic polyester polyols (20-22%) and petro-based Mannich polyols (approx. 17.5-19%)10.

*Click the image for greater detail

Table 15: Biobased polyols’ aromaticity.

In particular, among the polyols selected for rigid polyurethane foams testing, NX-9001 shows the highest aromatic content, due to its peculiar chemical backbone (alkoxylated cardanol novolac), followed by NX-9101 and NX-9008, with NX-9018 being characterized by a limited amount of aromatic rings in its chemical backbone.

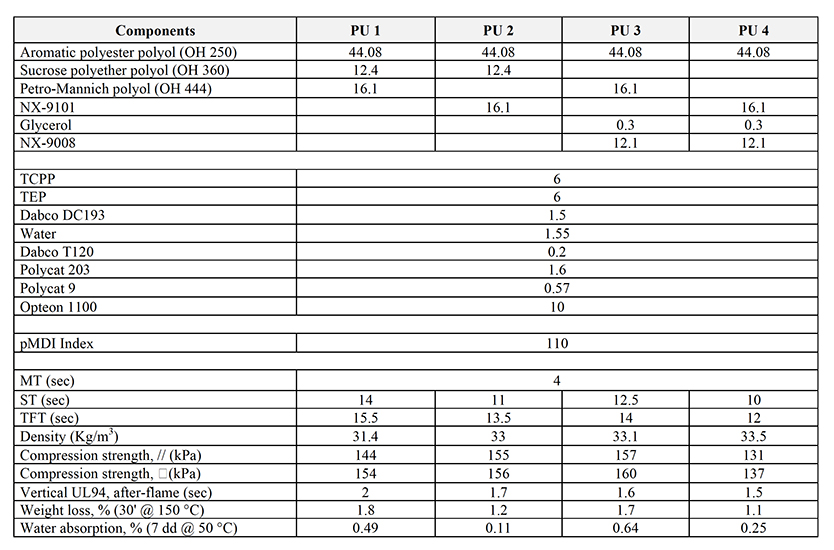

In a first round of trials (Table 16), cardanol-polyols have been used in a reference spray-foam closed-cell formula, benchmarking versus petro-based polyols characterized by comparable hydroxyl values. In particular, NX-9101 has been evaluated as potential replacement for a petro-Mannich polyol (formula PU 2), while NX-9008 as a possible alternative for a sucrose-based polyether polyol (formulas PU 3 and PU 4), still having the reference petro-Mannich polyol (formula PU 3) or NX-9101 (formula PU 4) as catalytic polyol. Since the hydroxyl value of NX-9008 is a bit lower than that of the reference sucrose-polyether polyol, a small amount of glycerol has been used to balance overall equivalent ratios.

In general, cardanol-polyol-based systems show faster reactivity than the fully petro-based reference, with a small increase in final density. All the formulations show average good compression strength values (in both directions); the only exception if formula PU 4, whose compression set is lower than the rest of the systems, most probably due to the higher overall cardanol presence, since the C15 side chain might have a plasticizing effect.

At the same time, thermal stability (measured as weight loss on a thermogravimetric scale set at 150 °C for 30 minutes) of partially modified cardanol formulas show a small improvement over the reference PU 1. A similar trend has been observed for weight variation after immersion in distilled water at 50 °C for 7 days, with PU 2, PU 3, and PU 4 showing low values in average, that are quite close or slightly better than the petro-benchmark. When characterized for their fire performances on a small scale (vertical UL-94), all the cardanol-based formulas (PU 2, PU 3, and PU 4) exhibit lower after-flame values than the fully petro-based reference.

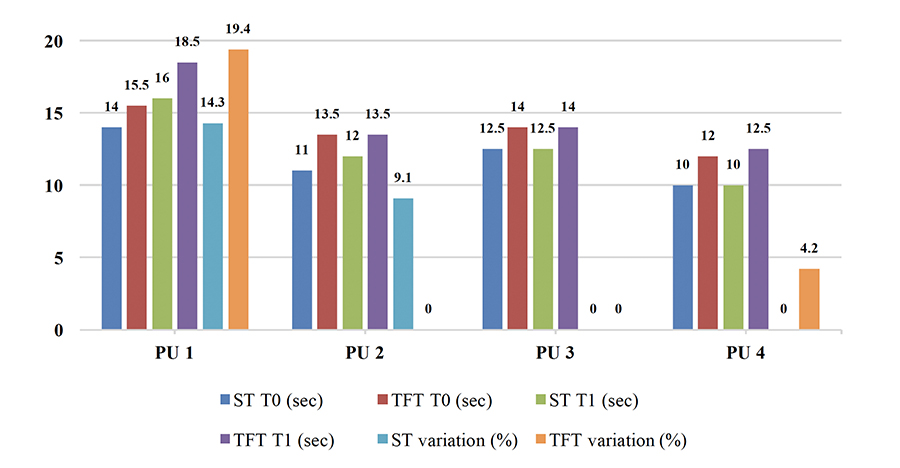

As an additional part of the study, the same formulations as in Table 16 have been tested for their stability over time. In this case, all the Parts B (polyol blends, additives, catalysts, silicone, and HFO blowing agent) have been stored at 50 °C for 7 days in tightly closed containers. Their reactivity has then been measured again using the same conditions as the fresh formulations (same pMDI, same index).

*Click the image for greater detail

Table 16: Fully-petro and partially-cardanol based formulations for spray foams.

As evident from the comparative data reported in Figure 9, CNSL-based formulations exhibit better stability after storage at 50 °C than the fully petro-based reference, with percentage variation values for both string time and tack-free time either very low or close to zero.

*Click the image for greater detail

Figure 9: reactivity variation of formulas PU 1, PU 2, PU 3 and PU 4 after accelerated ageing.

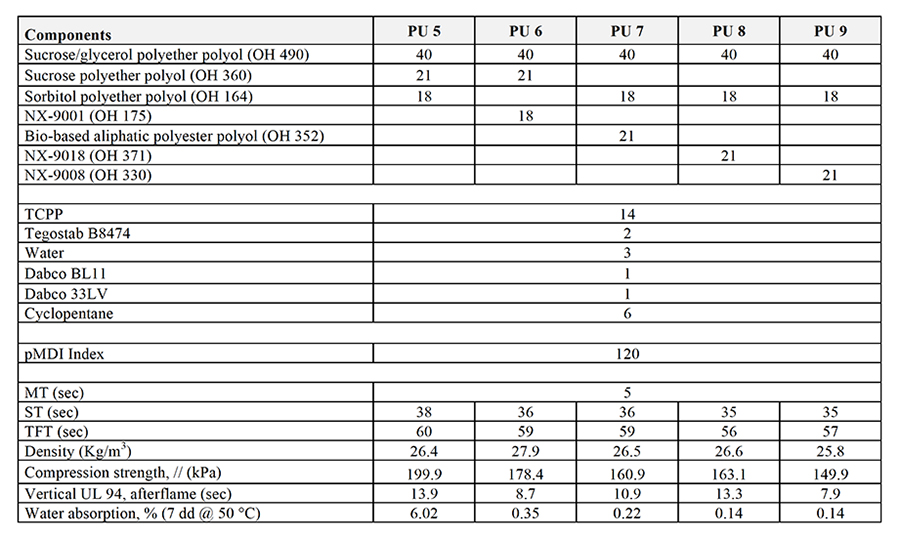

In order to confirm the versatility of the polyols described earlier for their performances in 2K PU coatings and adhesives, NX-9001, NX-9008, and NX-9018 have been tested in a different system for rigid polyurethane foams, characterized by medium reactivity (Table 17).

*Click the image for greater detail

Table 17: Fully-petro and partially-cardanol based formulations with medium reactivity (e.g. continuous panels).

In this case, formulations PU 5, PU 6, PU 7, PU 8, and PU 9 are all based on the same sucrose/glycerol polyether polyol (OH 490 mg KOH/g), with cardanol-polyols being used as full replacements for polyether polyols characterized by comparable hydroxyl value. In particular, NX-9001 (formula PU 6) has replaced a sorbitol-based polyether polyol (PU 5), while NX-9008 and NX-9018 have been used as potential alternatives to a sucrose-based polyether polyol having a 360 mg KOH/g hydroxyl value. A bio-derived polyester polyol with a similar hydroxyl value (PU 7) has been selected as a commercial bio-based benchmark.

All formulations show quite comparable or slightly faster reactivity than reference PU 5, with no significant difference in density. The lower compression strength values are most probably due to the more flexible structures of the alternatives polyols used in formulations PU 6-PU 9. However, the introduction of NX-9001, NX-9008, and NX-9018 significantly reduced the water absorption, not only with respect to reference PU 5, but also to the hydrophobic bio-based polyester benchmark (PU 7). At the same time, the presence of some aromaticity in polyols derived from the cardanol (NX-9001 and NX-9008), as expected, helped to reduce the after-flame values during vertical UL94 test.

Conclusion

Cardanol represents an ideal raw material for applications requiring environmental sustainability and easy processability. Its unique chemical backbone allows the development of polyols that can be successfully used in different polyurethane applications, ranging from coatings to adhesives to rigid foams. These polyols provide very good reactivity, hydrophobicity, chemical and corrosion resistance, adhesion, and mechanical and fire resistance properties. Excellent performances, wide formulation latitude, and low environmental impact are all aspects that qualify CNSL-polyols as valid alternatives to petroleum-based polyols.

Future work will be dedicated to the development of novel structures with increased UV resistance, high bio-content and further improved performances in different types of polyurethane systems (CASE, rigid and flexible PU foams).

Learn more at www.cardolite.com.

“Renewable, Cashew Nutshell Liquid-based Polyols: Their Benefits in CASE and Polyurethane Foams,” 2022 Polyurethanes Technical Conference 05-07 October 2022, National Harbor, MD, USA, Published with permission of CPI, Center for the Polyurethanes Industry, Washington, DC.

References

- https://www.statista.com/statistics/747004/polyurethane-demand-worldwide/(accessed 01-24-2022)

- https://ebrary.net/14418/environment/coatings (accessed 01-27-2022)

- a) Liu, Z.; Kraus, G. Green Materials from Plant Oils, Royal Society of Chemistry, 2014; b) Gandhi, T. S.; Patel, M. R.; Dholakiya, B. Z. Research on Chemical Intermediates 40, 3, 1223, 2014; c) Li, J.; Zhang, Y.; Li, W.; Wang, B.; Diena, P. WO2015077944; d) Balgude, D. B.; Sabnis, A. S.; Ghosh, S. K. Designed Monomers and Polymers 20, 1, 177-189, 2016

- Lomonaco, D.; Mele, G. and Mazzetto, S.E. Cashew Nutshell Liquid (CNSL): From an Agro-industrial Waste to a Sustainable Alternative to Petrochemical Resources, Springer International Publishing AG 2017, P. Anilkumar (ed.), Cashew Nut Shell Liquid

- Gedam, P.; Sampathkumaran, P. Cashew Nut Shell Liquid: extraction, chemistry and applications Prog Org Coat Vol. 14, Issue 2, 1986; pp115–157

- Natesh, A.; Campaner, P. Novel cardanol based polyols and their use in rigid polyurethane foams PU Magazine Vol.14, NO. 3, 2017; pp130-136

- Kim, Y.; Natesh, A.; Campaner, P. Outstanding performances of Cashew Nutshell Liquid based diols in polyurethane CASE and Foam technology. CPI Polyurethanes Technical Conference 2021, Proceedings of 2021 CPI Conference, Denver, USA, October 5-7, 2021

- Kim, Y.; Zhao, J.; Campaner, P. Cardanols as a versatile tool for 1K and 2K polyurethane systems: Non-toxic isocyanate blocking agent and minimization of moisture sensitivity. CPI Polyurethanes Technical Conference 2017, Proceedings of 2017 CPI Conference, New Orleans, USA, October 2-4, 2017

- Nodelman, N.; Hall, L.; Parker, W.; Shackelford, N.; Qian, J. Polyurethanes 2011 Technical Conference, 2011

- Ionescu, M. Chemistry and Technology of Polyols for Polyurethanes, Smithers Rapra Publishing, 2005

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!