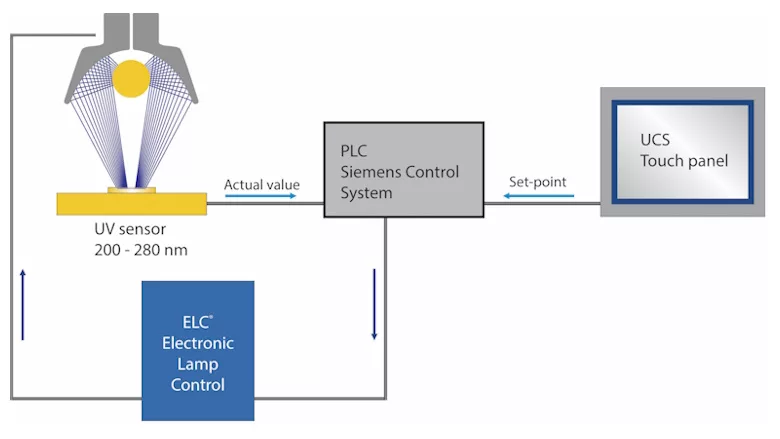

IST AMERICA: Control System

Image courtesy of IST America.

Adhesive manufacturers often require precise control over peel, tack, and shear, which are qualities that can be affected by UV lamp performance. While some systems offer basic monitoring, IST America has developed a Closed Loop Control system that provides fully automated, real-time UV lamp adjustment during adhesive curing.

The technology is integrated into IST’s Smart Control software platform and uses optional S5 sensors to measure UVC output directly at the lamp. This allows for continuous adjustment of curing intensity based on production speed, lamp aging, and other variables. The system maintains consistent curing conditions without the need for manual operator input.

Closed Loop Control is designed to help reduce material waste, improve consistency across production runs, and support optimal surface and through-cure balance. The feature supports both UVC (for surface cure) and UVA (for deeper cure) and is suited for manufacturers requiring high-performance adhesive results with repeatable process control.

IST’s Closed Loop Control is ideal for manufacturers balancing high-performance adhesive demands with a need for efficiency and repeatability, and it’s exclusive to IST America.

For more information, visit www.ist-uv.com/en-us.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.webp?height=200&t=1667684281&width=200)