IST AMERICA: Nitrogen Inert UV Curing System

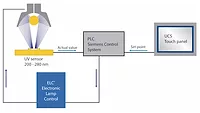

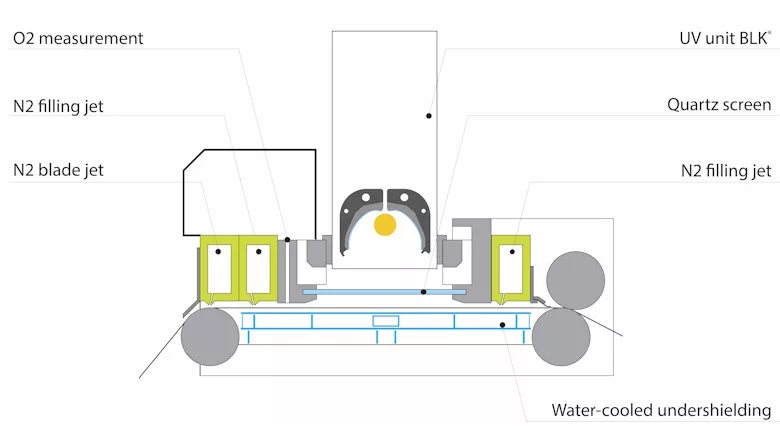

Illustration of IST America’s Nitrogen Inert UV Curing System. Image courtesy of IST.

Silicone coatings require high levels of UVC energy for effective curing. However, oxygen inhibition can hinder this process, often leading to increased ozone generation and energy inefficiencies. IST America’s Nitrogen Inert UV Curing System is designed to address these challenges by reducing the presence of oxygen in the curing environment.

The system includes a nitrogen distribution cabinet, custom-engineered low-oxygen chambers, and a continuous residual oxygen analyzer, all developed in-house and provided as part of the standard configuration. It also features a three-zone nitrogen chamber design that helps maintain consistent oxygen isolation and curing reliability.

Benefits of the system include improved energy efficiency, reduced oxygen-related curing interference, and continuous oxygen monitoring for enhanced quality control.

This solution is for those looking to upgrade an aging system, add a new line, or allow your tape customers to choose the curing system they prefer. IST delivers a fully supported, highly engineered solution.

For more information, visit www.ist-uv.com/en-us.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!