Solventless Silicone PSAs: Engineering Stronger, Safer Bonds Across Industries

From labels and tapes to screen protectors and electronic components, pressure-sensitive adhesives (PSAs) are all around us. PSAs are versatile adhesives that bond to surfaces when pressure is applied. With their ability to form strong, durable adhesive bonds, PSAs are an essential material across industries such as packaging, consumer devices, healthcare, and automotive manufacturing. The primary PSA formulations — acrylic, rubber, and silicone — each offer distinct advantages tailored to their intended applications.

Silicone PSAs, in particular, stand out for their flexibility, durability and resistance to extreme temperatures, chemicals, and moisture for a wide range of high-performance applications. With advancements in formulation, including solventless silicone PSAs, these adaptable adhesives are helping manufacturers address complex stability and environmental challenges.

Formulation of Silicone PSAs

The composition of silicone PSAs mirrors other organic-based PSAs, being composed of siloxane polymers and MQ resins, which together define their adhesive properties:

- Siloxane Polymers ("gum"): High molecular weight polydimethylsiloxane (PDMS) brings silicone PSAs excellent stability and flexibility as the longer bond length/angle and bond energy of unique -Si-O- connections.

- Silicate Tackifier ("MQ") resins: These highly condensed and specialized silicon resins help determine tack, adhesion strength, and shear resistance of PSAs. The name "MQ" comes from their structure: three-dimensional Q-unit core (SiO₄/₂) surrounded by M-units (R₃SiO₁/₂).

The Resin-to-Polymer (R/P) ratio is a critical factor in PSA performance optimization. For example, a high MQ resin content increases peel adhesion and strength, while a lower MQ resin content enhances flexibility and tack. Through a carefully balanced formulation, silicone PSAs can be engineered to meet the diverse needs of manufacturers.

Advancements in Silicone PSAs

In their raw state, silicone PSAs are typically thick or solid-like, requiring the use of solvents like toluene or xylene to lower viscosity and make the adhesive easier to work with during manufacturing and coating processes. While most silicone PSAs will exhibit pressure-sensitive behavior immediately after the solvent evaporates, they may require additional curing to reinforce the adhesive network.

- Peroxide-catalyzed curing: Uses varying levels of peroxide to enhance adhesive strength and shear resistance, resulting in a more tightly cured silicone PSA. This process requires specialized ovens, volatile solvents, and harmful by-products.

- Platinum-catalyzed curing: This process was introduced to address the concerns related to peroxide-catalyzed curing. Platinum-catalyzed curing cures silicone PSAs in a single-zone oven at lower temperatures, eliminating harmful by-products and accelerating production speeds.

Platinum-catalyzed curing has driven the development of solventless silicone PSAs, as it eliminates the need for aromatic solvents for any purpose other than viscosity control. With growing concerns over volatile organic compounds (VOCs), solventless silicone PSAs are emerging as a more sustainable, high-performing alternative to traditional solvent-based adhesives.

Solvent-based PSAs typically involve complex supply chain considerations, including storage, processing time, and significant energy use for evaporation, condensation, and transport. They also release VOCs and hazardous air pollutants (HAPs), leading to strict emissions regulations that may complicate manufacturing processes. Solventless PSA technologies, on the other hand, significantly reduce the use of harmful solvents like benzene, toluene, ethylbenzene, and xylene (BTEX), which can be released during the curing process and pose safety risks to both workers and the environment. While earlier solventless silicone PSAs may have faced performance challenges, recent advancements now match or exceed traditional formulations.

Application of Solventless Silicone PSAs

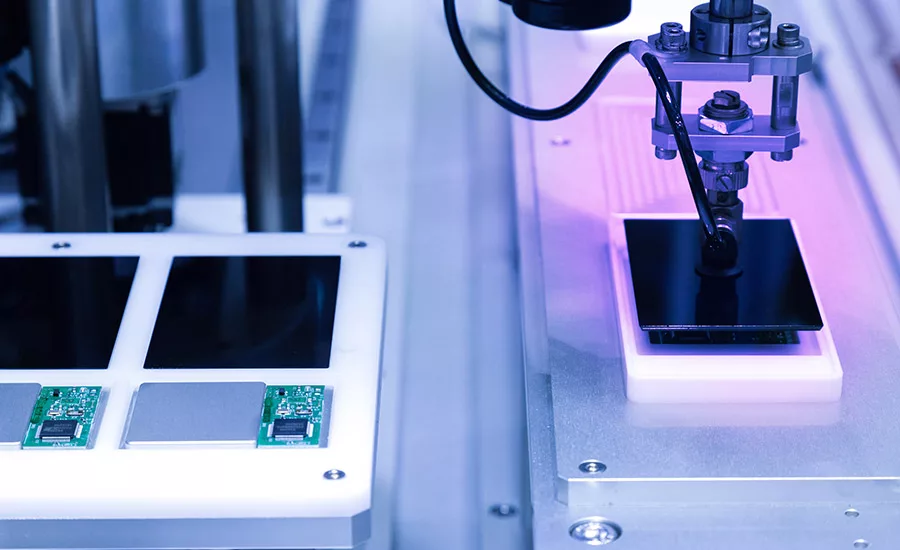

Solventless silicone PSAs are integral to demanding applications where the use of other adhesives may result in performance failure. In consumer electronics, for example, high-adhesion solventless silicone PSAs are commonly used for bonding touchscreen displays, securing battery assemblies, and attaching electronic components. Their versatility allows them to be used in everything from smartphones and tablets to cloud and data centers. Low-adhesion solventless silicone PSAs can also be used in electronics manufacturing in the form of protective films and other temporary bonding solutions that protect screens and displays.

Beyond consumer devices, the medical and healthcare industry relies on solventless silicone PSAs for skin-friendly medical tapes, wound dressings, and wearable biosensors, benefiting from their biocompatibility, breathability, and gentle removal properties. In automotive and aerospace applications, these adhesives play a vital role in securing EV battery components, insulating wire harnesses, and dampening vibrations in high-temperature environments, where conventional adhesives would degrade. Lastly, for industrial and specialty tapes, solventless silicone PSAs allow for high-temperature masking for powder coating and electronic circuit protection, maintaining adhesion even under extreme heat.

Looking Ahead for Solventless Silicone PSAs

As industries continue to demand higher performance, greater sustainability, and improved safety, solventless silicone PSAs are proving to be an essential advancement in adhesive technology. By eliminating harmful solvents and reducing VOC emissions, these next-generation adhesives address critical environmental and regulatory concerns without compromising performance. As research and innovation drive further advancements, solventless silicone PSAs will continue to play a vital role in engineering stronger, safer, and more sustainable adhesive solutions for the future.

Learn more about Dow at www.dow.comLooking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!