Breakthrough Developments in Very Thin Foams for Cushion-Mount Tapes

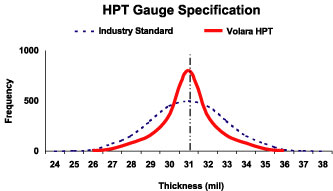

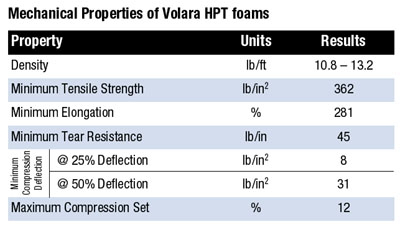

Voltek, Division of Sekisui America Corp., recently introduced a closed-cell, irradiated, crosslinked polyolefin foam, which is available in a thickness range of 0.012" to 0.075" and a density range of 8 to 20 lb/ft3. Volara HPT 0.012" is the thinnest crosslinked foam manufactured in North America. Volara HPT foams also offer the tightest gauge and density control in the industry along with superior mechanical properties. (See graph and table below.)

Unique Multistep Process

Voltek's multistep process is unique in that it first extrudes thin sheet. Next, the sheet is crosslinked via electron-beam irradiation. Finally, it foams vertically in an oven. (Expansion is between three and seven times in volume.) The development of Volara HPT required significant changes and improvements in all three manufacturing steps at an investment of 2.5 million dollars.The improvement of the automatic blending systems for the mixing of raw materials was the first step. This improved both the control of density from +/-20% to +/-10% as well as blend consistencies.

Next, the addition of a new wide-die and a Beta-gauge, closed-loop control system maintains thickness of the sheet in both the machine and cross-machine directions. Bernie Martin, process development manager, utilized his 31 years of foam-processing experience coupled with the experience of the die manufacturer in developing a unique, high-performance die designed specifically for the production of thin sheet within 0.00020" tolerances. Martin says, "The improvement realized in gauge tolerances was so significant that we have begun adding new dies with closed-loop control to all of our existing equipment."

Tension control and width capabilities of the ovens were the two major areas that needed improvements for the foaming of Volara HPT. First, the tension control was a unique problem because two different materials (solid thin sheet and foam) are unwound and wound during the foaming process. The solution was for Voltek to design and implement a system that utilizes sophisticated winding capabilities. Second, with wide thin-extruded sheet, the production of Volara HPT at widths of up to 62" was possible, and the ovens needed to be modified to accommodate foams at these widths.

By increasing the oven-width capabilities, a second benefit was realized. Voltek is now capable of producing 4 lb/ft3 and 6 lb/ft3 foams at widths greater than 80" wide. The wide width allows customers with secondary processing equipment to utilize their machinery to the fullest capabilities.

Other Benefits Realized

Because of the improvements made in extrusion, irradiation and foaming, other benefits have been realized. First, Volara HPT offers density and thickness tolerances that are the tightest in the industry. For example, Volara HPT 0.020" has a density range of +10% with a cross-machine gauge variation that is typically 0.0020" or less. Second, Volara HPT can be manufactured at lengths of 4,500 ft with 0 to 3 splices per roll. This allows customers to run their processes with fewer interruptions in production.Voltek is continuing to improve not only the Volara HPT grades but also all other grades of foam. The company is currently in the process of adding state-of-the-art in-line gauge measurement devices to its foaming process. The ultimate goal is the ability to add a closed-loop control system to the foaming process.

With the introduction of Volara HPT, Voltek has raised the bar on quality and consistency of crosslinked polyolefin foams. Future achievements expected from Volara HPT and Voltek are: density specifications of less than 10%, overall gauge specifications of 0.0010", rolls of foam that are one-mile long, elimination of the effect of gauge banding and foam at a thickness of 0.008".

The Volara HPT and other advances have all been driven by the market's need for thin, soft and flexible foam with superior properties and tolerances. It is expected that the Volara HPT grades will be extensively used for cushion-mount tapes in the flexo-printing industry, low-profile mounting applications, transdermal drug delivery and gasketing. In many cases, Volara HPT is seen as an attractive alternative to higher-cost acrylic and urethane foams.

Additional information on Volara HPT is available from Voltek, Division of Sekisui America Corp., 100 Shepard St., Lawrence, MA 01843; phone 978-685-2557; fax 978-685-9861; or visit the Web site www.voltek.com. Or Circle No. 259.

Links

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!