Tape Talk

Developments in Plasma and Flame Surface Treaters for Improving Adhesion

Ongoing advancements with plasma and flame surface treaters are expanding the systems’ use in a growing number of industries.

Fig. 1. Blown-arc™ discharge.

Fig. 2. Blown-ion™ plasma discharge.

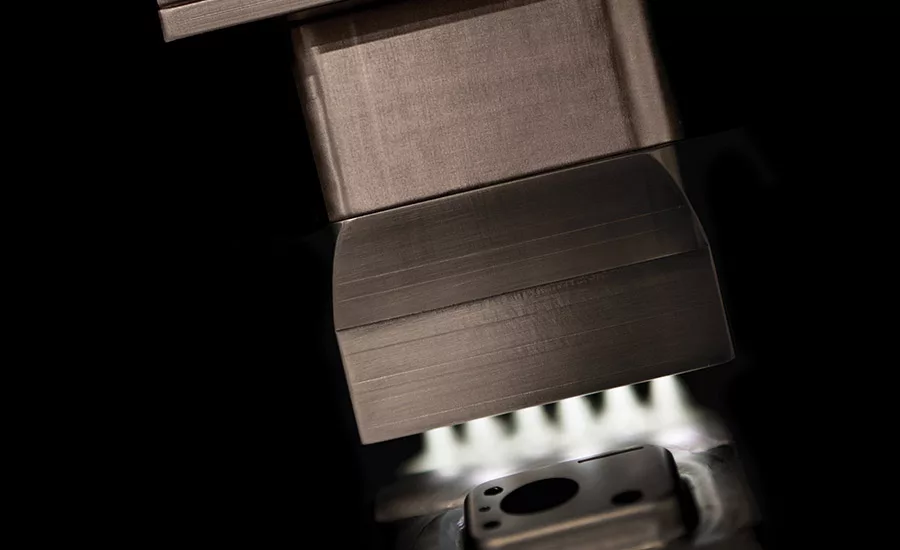

Fig. 4. Flame treater for automotive applications.

Fig. 5. Blown-ion plasma treater.

Fig. 6. Flame treater.

Industrial assembly and decorating operations are increasing their use of atmospheric plasma and flame surface treaters to improve adhesive bonding. These safe and green technologies activate surfaces to enable stronger bonds with plastics, composites, wood, glass and metal surfaces. In some cases, they enable adhesion and increased productivity. In others, they eliminate hazardous surface preparation materials and reduce the costs of adhesives. Their ability to be integrated as an automated solution provides manufacturers with a reliable and consistent process. Ongoing advancements with plasma and flame surface treaters are expanding the use of these systems in more and more industries.

Why Surface Preparation is Needed

Think of a freshly waxed car. What becomes of the rain that falls on its surface? It beads up into droplets, rather than wetting out on the surface. This is how non-porous and hydrophobic surfaces with inherently low surface energy interact with liquids. The cohesive forces of liquid are stronger than the adhesive forces between the liquid and the surface.

Further complicating the adhesion equation can be additional surface contamination and additives that bloom to the surface to interfere with bonding. Surfaces that lack proper bonding sites due to low levels of charged ions on the surface require some form of preparation to enable adhesion.

Traditional methods of surface preparation include liquid primers, mechanical roughening and vacuum plasmas. Each method may be effective with specific application requirements. However, liquid primers can be expensive, messy, and environmentally hazardous, and may not be conducive to an in-line process. Mechanical preparations are often not delicate enough for sensitive surfaces and can generate surface debris. In addition, unless fully automated, these processes can be subject to human error. Vacuum plasma treatment, on the other hand, can be very effective, but also expensive and limited to batch, offline processing.

In-line atmospheric plasma and flame treaters offer an automated solution as they can be mounted over conveyors, with indexing systems, or integrated with robotics for precision applications.

How Plasma and Flame Treating Works

Atmospheric plasma and flame treaters clean, micro-etch and functionalize surfaces to promote adhesion, improve quality, and increase productivity. Plasma and flame species react with the surface by vaporizing low-molecular-weight contaminants. The process removes organic and many inorganic impurities and contaminants, exposing a clean surface for improved adhesion.

Surface treaters also micro-etch polymer surfaces—as charged ions, neutral atoms, and radicals—in both the plasma forming gas and the reactive process gas―bombard the surface. Increasing surface area creates more bonding sites, which promotes adhesion success.

Plasma and flame activation, or functionalization, is the concurrent process of using radicals to break up surface polymer bands to create crosslinking of surface molecules. This process increases polar groups, which directly contributes to the surface’s adhesion properties.

Flame Surface Treaters

Due to its longevity, flame treating is the most common technology. However, today’s flame treaters are equipped with safety features and combustion control technology that far surpasses their predecessors. Flame treaters offer powerful treatment that is efficient, safe and repeatable.

A plasma field is formed when flammable gas and air are combined and combusted to form an intense blue flame. Brief exposure to the energized particles within the flame affects the distribution and density of electrons on the substrate’s surface and polarizes surface molecules through oxidation.

Flame plasma treatment also deposits other functional chemical groups that further promote wetting and adhesion. Flame plasma treatment generates more heat than other treatment methods, but creates greater surface energies with a longer shelf life relative to corona.

Both conductive and nonconductive materials can be treated with flame at extremely high speeds. Treatment width can vary from as small as 2 in. to several feet. The effective treatment area of the flame is very deep, which allows treatment of objects with significant contours.

Blown-Arc Discharge Plasma Treaters

The most basic atmospheric plasma is referred to as a blown-arc discharge (sometimes also known as corona treatment). Blown-arc air plasma is formed by blowing atmospheric air past two high-voltage power electrodes. A typical blown-arc treatment head can treat areas between 2 and 3.5 in. wide.

This technology is generally capable of achieving treatment results at only low and moderate processing speeds of less than 50 ft/min. It also has limitations in that it cannot treat conductive materials. This is an important consideration, not just for the material being treated, but also for any carriers that may be involved in handling the surfaces being treated.

Blown-Ion Discharge Plasma Treaters

Blown-ion air plasma systems are capable of treating both conductive and nonconductive surfaces. With this technology, pressurized air is blown past a single electrode, which (unlike blown-arc technology) discharges inside the treater head. The electrode creates positively charged ions in the surrounding air particles. The air pressure forces the air particles to accelerate out of the tip of the head as a high-velocity stream of charged ions is directed toward the substrate surface. Through direct contact, these particles positively charge the object’s surface, increasing its surface energy and making it more receptive to inks and coatings.

Traditional blown-ion systems were limited in treatment width of 3/8-5/8-in. wide in a single pass. For wider areas or extended treatment paths, automation or robotics can be used. Some manufacturers have developed rotating blown-ion discharge heads to cover larger areas. These rotating head systems can be effective under certain applications conditions; however, there can be inconsistencies in treatment levels and effective processing speeds are of a moderate to low level.

A new development in blown-ion plasma technology was introduced at the NPE Show that expands the ability for blown-ion plasma treating for wider widths and higher line speeds. The new design is capable of treating up to 2 in. wide in a single pass and offers more treatment power than its predecessors.

Adhesive Bonding Applications

Applications for improving adhesive bonding can be found in numerous industries. In the automotive industry, plasma and flame systems are commonly used to improve adhesion of automotive head lamp assemblies and structural adhesives used in body parts such as spoilers. Other decorative and manufacturing automotive applications include dashboards, bumpers, decaling, painting, and the production of many components such as gaskets, filters, seals, and mirrors.

Industries that rely on composites are also investigating the benefits of plasma treating. In the aerospace industry, for example, structural bonds are mission critical and plasma presents an opportunity to automate current processes and improve efficiencies and reliability.

Furniture and window and door manufacturers are also finding success with flame and plasma surface treating. These technologies are enabling adhesion on window and door frame assemblies and decorative wraps on furniture.

In the folding carton industry, plasma is used to improve the adhesion of polypropylene laminated glue flaps of a paperboard folding carton. In many of these applications, hot-melt adhesives are replaced with cold-set adhesives.

In addition to adhesives, plasma and flame treating are also effective at promoting adhesion of sealants and inks. Many electrical potting applications benefit from in-line treating as well.

Testing Surface Treatment

The best way to determine if plasma or flame will work for a specific application is to put it to the test. Many surface treating manufacturers offer free laboratory testing and trials in live production environments.

When selecting the best technology for an application, it is important to take into consideration how the equipment will be integrated into the production line. Will parts be presented to the treatment head? Do the parts need to be moved in order to expose all the surfaces that need treatment? Will the surface treatment head be in a fixed position or integrated with automation to achieve the desired results?

Plasma and flame technology are continuing to develop and are being used in more and more industries and applications. Consult with a plasma and flame surface treater manufacturer for expert advice on the best solution for your operation.

For more information, visit www.enerconind.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!