Keeping It Together

As components shrink, so do the devices themselves. Electronics manufacturers find themselves left with dwindling amounts of space to include fasteners. Even tape and adhesive bonding has to be accomplished using dramatically less surface area to hold components and casings in place.

Traditional assembly technologies are being pushed to their limits. Ultrasonic welding does not work well with dissimilar materials and can leave cosmetic defects on thin plastic parts. Instant adhesives, such as cyanoacrylates, can attack and cause crazing in many new, low-cost plastic materials. Pressure-sensitive tapes and adhesives are limited in strength when used in narrow bond areas that are less than two millimeters in width. When manufacturers do choose to use adhesives or tapes, advanced application technologies are needed to make it possible to use them efficiently and effectively.

Manufacturers are constantly scrambling to find "small" ways to solve big challenges like this. Some companies are working together to bring total solution packages to their shared customers. 3M and Liquid Control Corp. have connected to introduce a complete adhesive application system designed to replace ultrasonic welding for precision bonding in the manufacture of electronic devices.

"The electronics industry is changing rapidly and we, as manufacturers and suppliers, have to keep pace in finding solutions as challenges arise," said Jamie McCormick, Business Development manager with 3M Electronics Markets Materials Division. "One of those challenges is the need for thinner bond lines in bonding plastic materials."

3M is well known as an innovator in adhesive and tape technology that solves customer problems like those faced by the electronics industry. Liquid Control is a leading provider of mixing and dispensing equipment in the rapidly growing electronics industry.

"3M and Liquid Control often work with the same companies to develop solutions that combat the same issues," said Brad Smith, Product manager with Liquid Control. "Together, if we can offer our customers a turnkey operation that lowers their overall assembly cost and improves efficiency, then we're acting as a true partner and helping to advance their business."

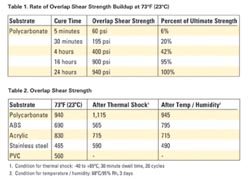

Bonding Adhesive 2665 is a one-part, hot-melt, moisture-curing adhesive. The adhesive is applied at 230

Table 2 illustrates the overlap shear strength of various substrate materials tested at room temperature ambient conditions after thermal shock and temperature/humidity tests.

Assembly Solutions Improve Product and Productivity

Cartridges of Bonding Adhesive 2665 fit in automated production lines with a variety of dispensing equipment. Liquid Control Corp. has developed the 1053 MicroMelt Precision Dispensing Valve, which can be combined with motion platforms, such as the company's C-500 or C-450, to provide precise, automated dispensing. The 1053 valve precisely and automatically dispenses in volumes from 0.002 cc to 3.6 cc. The motion platform uses Microsoft® Windows®-based programming for custom plotting XYZ application of adhesive. The robust and precise actuators ensure uniform bead and dot size and continuous dispensing paths in 2- and 3-D motion. Variable and independent acceleration and deceleration provide for optimum dispensing and assembly speed. Beads and dots of varying sizes and continuous dispensing paths are automatically applied.Conclusion

As the electronics industry continues to change, remaining competitive means keeping in the forefront of materials and manufacturing technology. Expensive upgrades in equipment and assembly techniques can be costly concerns for manufacturers and assembly plants. Materials and equipment suppliers working together to provide solutions to those concerns can provide advantages to everyone involved. According to McCormick, even in an industry that is all about circuits and materials, relationships continue to be key to progress.For more information about 3M, phone (800) 567-1639 ext. 8184 or visit http://www.3M.com/electronicmaterials .

For more information about Liquid Control Corp., visit http://www.liquidcontrol.com .

3M is a trademark of 3M. Other trademarks may be the property of their respective owners.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!