Pure Monomer Resins - Fine Tuning Adhesives Formulations for Demanding Applications

A familiar example can be found at the deli counter of any supermarket. Ready-to-eat meats frequently come in resealable packaging that includes a combination of rigid and flexible plastics. This application requires an adhesive that can seal and re-stick to multiple types of plastic, even when exposed to meat juices. The adhesive must also be low color to meet consumer preference and comply with FDA regulations for direct contact with food. An application such as this requires a complex adhesive formulation.

Pure monomer resins (PMRs) are an ideal solution for such challenging applications. They can provide formulators with the tools needed to fine-tune adhesives formulations to meet specific application requirements without affecting other key performance properties.

Why Pure Monomer Resins?

PMRs occupy a unique space in the range of tackifying resins available to adhesives formulators. Made from purified aromatic starting materials, PMRs offer the best of both worlds: the compatibility and versatility of aromatic resins along with the clarity and stability of a hydrogenated aliphatic resin. This means that PMRs are compatible with various base polymers and provide low color, good thermal stability, and excellent resistance to weathering. In addition, their verifiable composition allows them to be compliant with FDA direct food contact regulations.

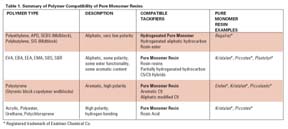

PMRs offer compatibility with a range of base polymers, such as polyethylene, ethylene vinyl acetate (EVA) copolymers, amorphous polyolefin (APO), styrene-ethylene-butylene-styrene (SEBS), styrene-isoprene-styrene (SIS), styrene-butadiene-styrene (SBS), styrene-butadiene rubber (SBR) and polychloroprene-based adhesives, as well as acrylics, some polyesters, and aromatic isocyanate-based urethanes (see Table 1). This allows broad flexibility in material selection when formulating adhesives for more demanding applications.

Low Color

PMRs have very low color, which helps to formulate a clear adhesive. This is a key property in any adhesives formulation used in food packaging, microwavable packaging and nonwoven applications where yellow- or brown-colored adhesive is visually unappealing to the consumer. PMRs also have good thermal stability, allowing the adhesive to be held at application temperature longer without excessive color or viscosity change.

Temperature Resistance

PMRs can also be used to improve the ability of an adhesive to maintain its cohesion at higher temperatures. All hot-melt adhesives have a characteristic temperature at which they soften to the point of failure when under stress. This is determined experimentally as the shear adhesion failure temperature (SAFT). Increased temperature resistance allows the formulation of adhesives with higher SAFT points without sacrificing tack and adhesion properties.

While there are many adhesives applications that do not require their use, PMRs are the optimum solution when compatibility, low-color, temperature resistance and application viscosity control are critical.

Pure Monomer Resin Applications

When all the families of PMRs are considered, they cover a range of properties. However, to select a specific PMR for a given application, it is important to understand what specific adhesive performance properties are required.For example, the converting equipment used to apply adhesives often requires a narrow window of viscosity or application temperature to precisely control either the pattern or weight of the adhesive, or to avoid distortion of the substrate. To control costs and reduce the risk of product failure, it is crucial to select the right PMR to fine-tune the viscosity for a specific piece of equipment or to achieve better control of the overall manufacturing process and adhesive application.

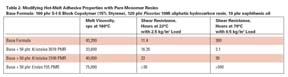

Adding a PMR with a high glass-transition temperature (Tg) - greater than 95°C - will increase temperature resistance, ambient temperature shear and melt viscosity (see Table 2). This enhances the ability of an adhesive to perform at higher temperatures, but it also increases the viscosity and application temperature. Meanwhile, adding a PMR with a lower Tg - 50-95°C -will decrease melt viscosity, SAFT and application temperature, but it will increase ambient temperature cohesion (see Table 2). This would be appropriate for applications where hitting a narrow application viscosity window is crucial without sacrificing room-temperature cohesion. Finally, adding a PMR with a Tg of less than 50°C will sharply decrease melt viscosity and reduce the required application temperature with some decrease in ambient temperature cohesion.

For adhesives applications that are used in food packaging, it is also important to make sure the PMR being considered is FDA compliant. PMRs have a range of FDA clearances, including some for applications in direct contact with food.

Conclusion

To meet the requirements of demanding adhesives applications such as automotive tape, various food packaging and nonwoven assembly, formulators need to fine-tune hot-melt adhesives - creating precision adhesives - without decreasing overall adhesive performance and effectiveness. In many cases, FDA compliance is also a requirement. PMRs are an ideal additive for formulators looking to achieve the right level of adhesion and cohesion, temperature stability and viscosity while maintaining clarity and performance.

With a clear understanding of application requirements, formulators can use PMRs to control specific performance properties, allowing them to formulate adhesives to meet the needs of these challenging applications.

For more information, contact Eastman Chemical Co., phone (423) 229-2000 or visit www.tackifier.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!