Radiation-Curable Pressure-Sensitive Adhesives

Radiation-curable pressure-sensitive adhesives provide advantages for multiple applications.

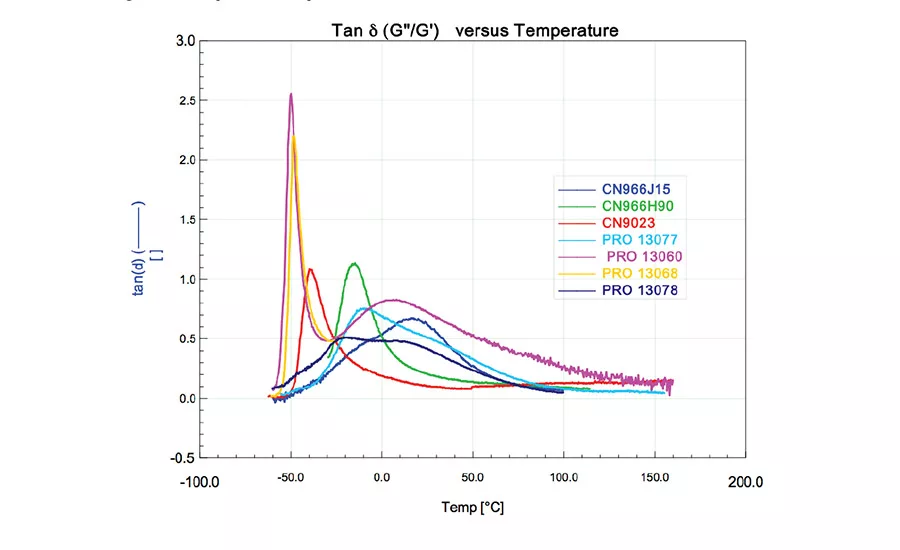

Figure 1. Temperature dependence of storage modulus (G’) of oligomers.

Figure 2. Temperature dependence of tan (d).

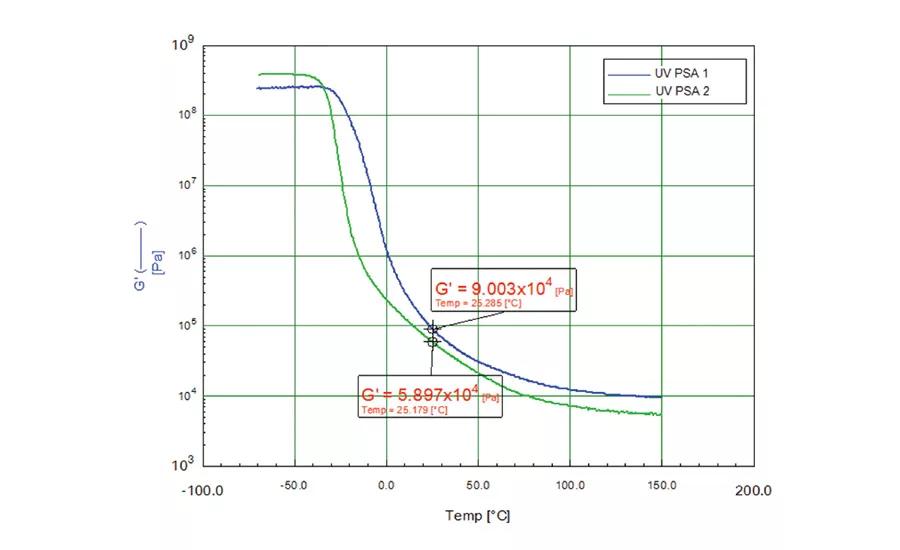

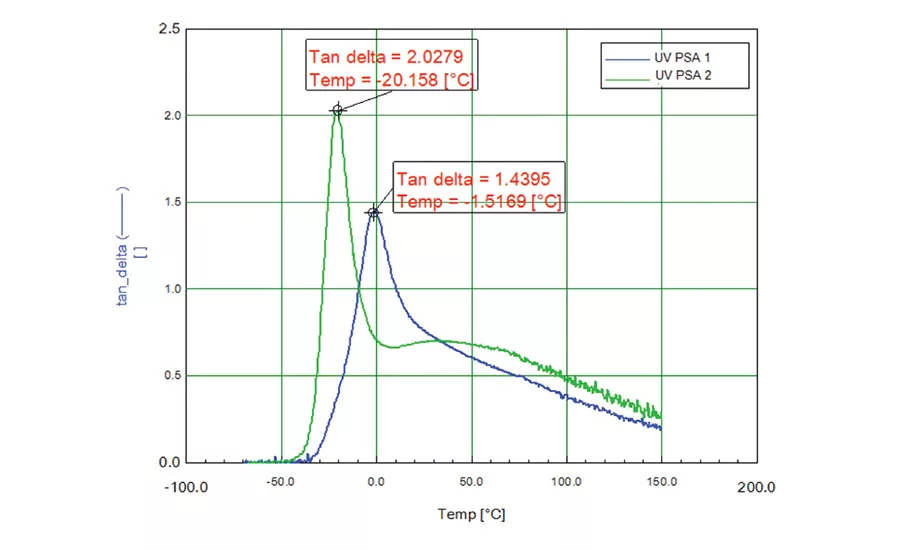

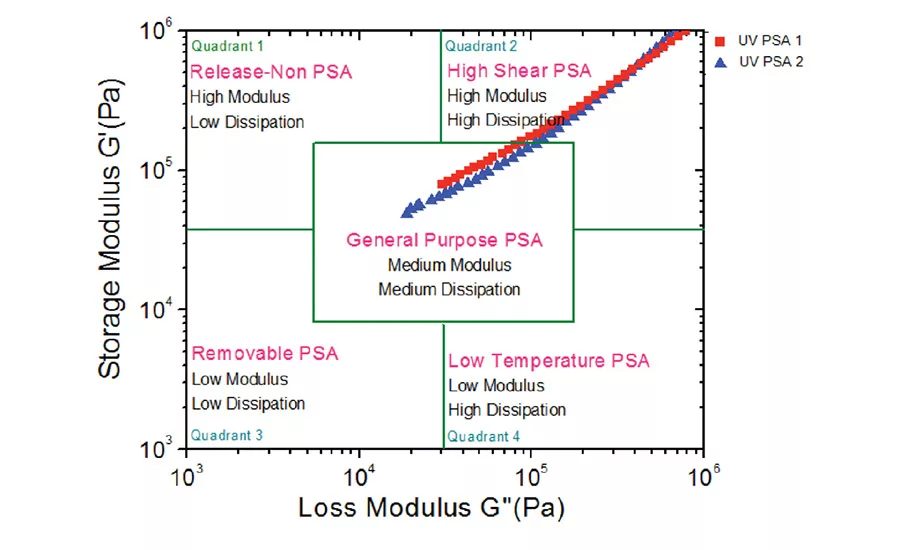

Figure 3a. Temperature dependence of storage modulus (G’) of UV PSA 1 and UV PSA 2.

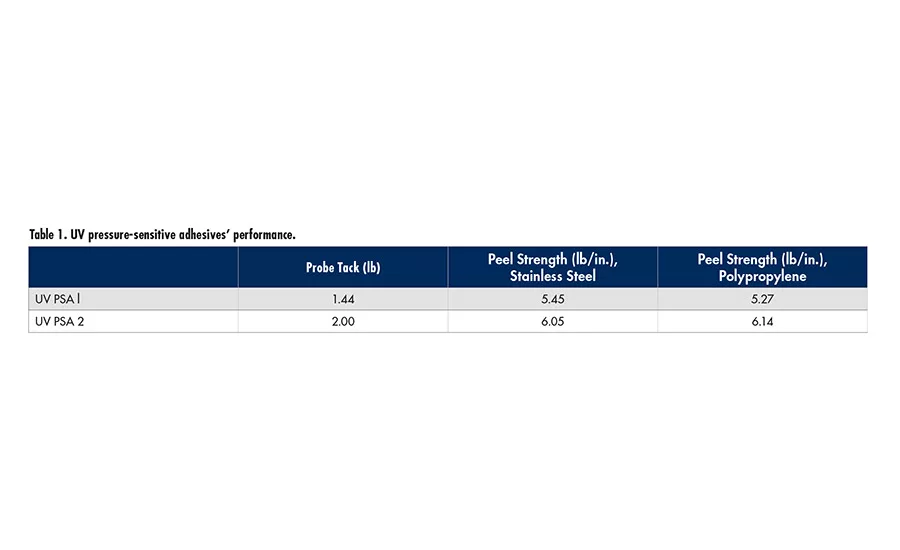

Table 1. UV pressure-sensitive adhesives’ performance.

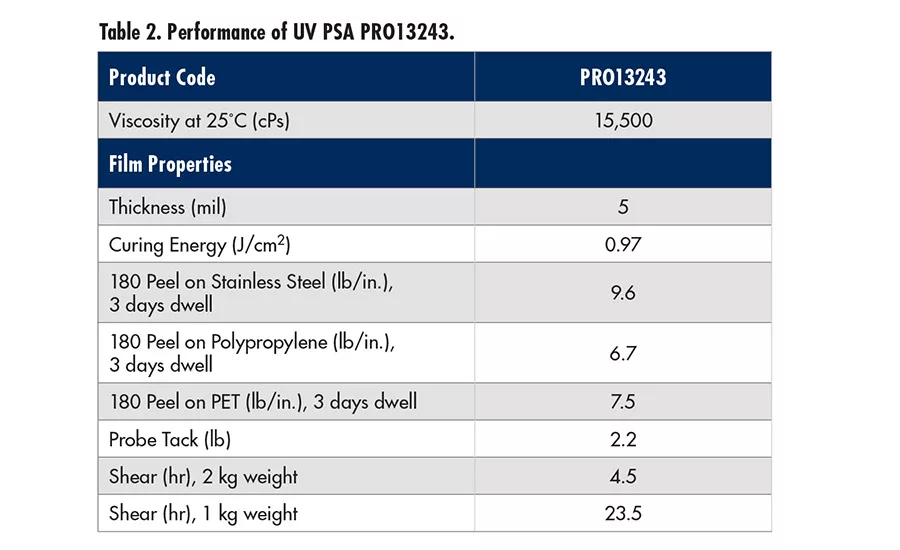

Table 2. Performance of UV PSA PRO13243.

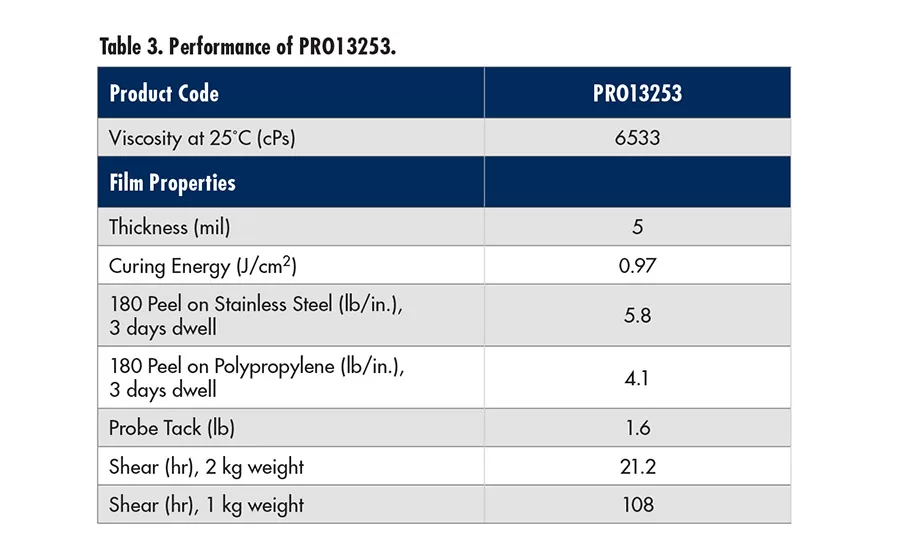

Table 3. Performance of PRO13253.

Regulations on volatile organic compound (VOC) emission have caused solventborne pressure-sensitive adhesives (PSAs) to be gradually replaced by hot-melt or waterborne PSAs. However, for industrial specialty tape applications, solventborne technology still dominates. This is mainly because hot-melt and waterborne PSAs cannot deliver high enough performance, including high peel strength, high tack, and high shear. With the more stringent regulations on VOCs, there is an urgent market need for a new technology to replace solventborne systems for such specialty applications.

Over the last two years, a series of innovative formulated products have been designed and developed to provide a solution to this market need. For example, a 100% solids radiation-curable syrup system can deliver the high performance that industrial specialty tape requires. The key benefits of this technology include, but are not limited to:

• 100% solids without VOCs

• High productivity

• No heat required during converting process

• High performance on both high- and low-surface-energy substrates

Experimental

Radiation-curable syrup PSAs were developed based on specially designed oligomers and by comprehensive formulations. The viscosities of formulated adhesives are in the range of 5,000 to 20,000 cps.

Sample Preparation

The PSAs were drawn down onto the surface of 2-mil untreated PET film. The adhesives were cured under a 400 W/in.

mercury vapor lamp at about 1 J/cm2 curing energy. Afterward, the samples were laminated onto a release paper and 1-in. strips were cut for testing.

180° Peel Strength

The samples were prepared by applying 1-in. PSA strips to stainless steel or polypropylene panels using a 4.5-lb automatic roller. The laminated samples were dwelled at 72°F and 50% humidity for three days before testing. The peel strength was measured at a 180° angle at a speed of 12 in./min following the ASTM D903-98 standard.

Probe Tack

The probe tack was measured following ASTM D2979-95 using a Probe Tack Tester PT-500 from ChemInstruments.

Shear Resistance

Shear resistance was tested following ASTM 4498-95. One square inch of adhesive samples was applied to the stainless steel panels and dwelled for one hour before testing. Weight of either 1g or

2 kg was used, and the time was recorded.

Rheology Property

Dynamic mechanical analysis experiments were done on TA Instruments’ RDA111 rheometer at a frequency of 1 Hz and a heating rate of 3°C/min. All samples were tested using a 8-mm parallel plate, applying a static compressive force, and in shear mode in the linear viscoelastic region. The peak tan d temperature and storage modulus G’ at 20°C are reported. Frequency sweep were done at 30°C in RDA 111, using 8-mm parallel plates from 0.01 rad/s to 100 rad/s.

Results and Discussion

The rheology of several commercial oligomers was studied. It was found that the storage modulus at room temperature and tan d of these oligomers are relatively high for PSA application. This requires significant formulation work to achieve the high performance. Several new oligomers were designed and synthesized to lower the storage modulus at room temperature and tan d. PRO13077 lowered the storage modulus close to 105 Pa at plateau and stabled up to 150°C, which can be easily formulated to PSA. The storage modulus of PRO13080 is lower than 104 Pa, which indicates this oligomer can form a soft but elastic film having cohesive strength up to 150°C. The oligomer itself can function as a PSA. As a comparison, the storage modulus of PRO13068 3 does not show a rubbery plateau region on temperature sweep, indicating that this oligomer cannot be cured to an elastic film. After curing, it will function more like a viscoelastic polymer. The storage modulus of PRO13078 is similar to CN966H90.

Comprehensive formulations were designed and tested based on PRO13077 and PRO13080. A series of new high-performance UV-curable PSA products were developed. These 100% solids, UV-curable syrup products have viscosity from 2,000 to 20,000 cps at room temperature, which enables the converting process without or with minimum heat. Due to the correlation of viscoelastic properties of PSAs with industry-standard performance,1 the viscoelastic properties of cured PSAs were used as screening tools for this high-performance PSA development. Typical viscoelastic properties are presented in Figure 3 (p. 18).

The examples of UV PSA 1 and UV PSA 2 are given. Based on Dahlquist contact criterion,2 tack did not occur when storage modulus was greater than 105 Pa (this theory was evidenced by the data).

The UV PSAs offering excellent tack properties at room temperature do have a storage modulus lower than 105 Pa. Table 1 presents the PSA performance of two examples, and Figure 3 presents their rheology properties. UV PSA 2 has lower storage modulus and lower Tg compared to UV PSA 1. These properties enable better wetting of the substrates, showing higher tack and peel adhesions. The viscoelastic windows of these two UV PSAs show that both of them are in quadrant two and the central area corresponding to comparatively high/medium modulus (G’) and high/medium dissipation (G”) within the application rates (i.e., between 10-2 and 102 sec-1). In general, this implies higher shear performance.

With further tuning of oligomer design and formulation, the best UV PSA product protocol can achieve high peel and high tack adhesion properties on both hydrophilic substrates (such as stainless steel) and hydrophobic substrates (such as polypropylene) at room temperature. PRO13243 shows excellent adhesion on stainless steel, polypropylene and untreated film PET. It also shows reasonable shear resistance. This product is suitable for a variety of different industry applications, such as permanent tape or transfer films. PRO13253 shows higher shear resistance, improving the shear resistance four times longer at the expense of peel strength. Overall, it presents balanced peel and tack adhesion and shear resistance. It is suitable for a variety of industry and commercial tape applications. Preliminary studies also indicate these two products have good heat resistance. The PSA performance can be maintained after exposure to 150°C for 3 hrs.

Conclusion

Solventborne PSAs continue to be challenged by low VOC regulations. The specialty solventborne systems are difficult to be replaced by hot-melt or waterborne PSA systems due to their high performance requirements. Radiation-curable technology demonstrates an advantage in offering such high performance. Through the special design of functional oligomers and formulation tailoring, UV-curable syrup PSAs can offer the high peel and tack adhesion to both high- and low-surface-energy substrates and high cohesion at room temperature. The adhesives can be easily coated at room temperature or slightly warm temperature as needed to cure up to 5 mil thickness. ASI

For more information, visit www.sartomer.com.

Acknowledgment

The author would like to thank Jinping Wu for her contribution.

References

1. “Viscoelastic Properties of Pressure Sensitive Adhesives,” Journal of Adhesion, 60:1-4, 233-248.

2. C.A. Dahlquist, Proc. Nottingham Conference on Adhesion, Part III, Ch. 5, p. 134.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!