Case Study

Improving Operations with ERP

The introduction of an enterprise resource planning system has streamlined operations for a manufacturer of automatic web splicing equipment.

Why would a relatively small business choose to make the significant investment needed to implement an enterprise resource planning (ERP) system? There are many answers to that question, including streamlining engineering processes, improved inventory management, better costing knowledge, and more efficient financial reporting. This information is often extremely difficult to extract from legacy manual systems that rarely talk to each other.

Selecting the right ERP system is just the first step. Management commitment is needed for the software, training and implementation time required. The following shows how implementing an ERP system allowed Butler Automatic to reduce its lead times for building machines, as well as improve its financial reporting.

Selecting a System

Butler Automatic is a global manufacturer of automatic web splicing equipment for food, pharmaceutical, printing and consumer packaged goods markets. By 2013, it had become apparent that it was not possible to get adequate reporting on sales and cost information from Butler’s legacy business system without a lot of time-consuming, manual data manipulation.

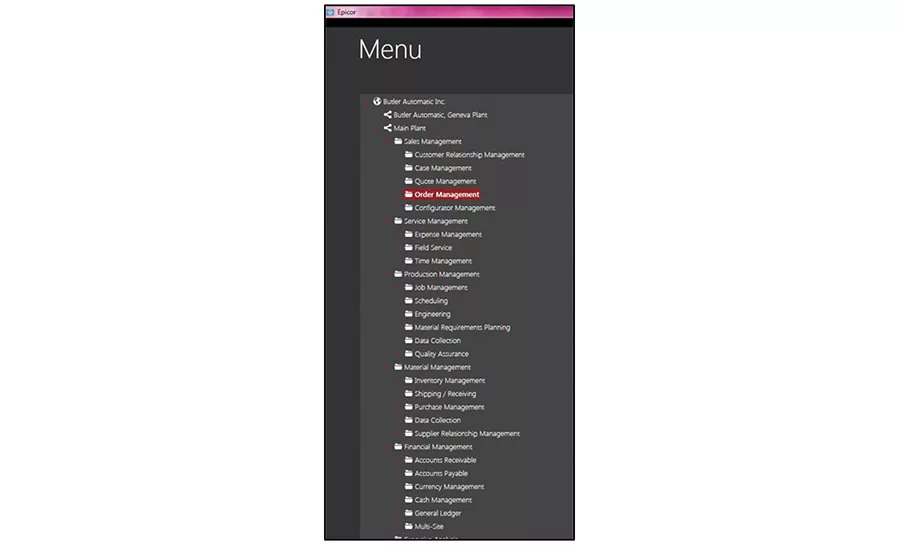

After working with a consultant to determine ERP system requirements that would help with the goal of improving machine order-to-ship time, as well as controlling inventory, Butler interviewed several potential software suppliers and put a contract out to bid. The system had to be a full “quote-to-cash” system, including quoting, order entry, buying, production, service, and parts sales. A range of accounting functions was also needed, including an ability to export directly to financial statements. After analyzing the bids, Butler eventually selected Epicor ERP, which contains specific modules focused on reducing costs, streamlining processes, and improving customer responsiveness across the enterprise.

Efficient Implementation

Butler contracted with ComTec Solutions to assist with implementation in 2014; the system went live in 2015. Efficiency was the implementation mantra. The management team wanted to be able to use the software tools to track data, but without having to hire a team whose sole job was collecting and entering data.

Implementation did not come cheaply. The cost of the hardware, training and software amounted to more than $300,000. In addition, five staff members from different departments within the company spent an hour each day outside of their regular jobs for 10 months learning the software and preparing for implementation.

“We ran through the process every day to review how it would work,” said Mary K. Weiser, Butler’s director of finance and administration. “We tweaked it and made adjustments to make it work well in our environment.” The project implementation team also spent hours preparing old data to import it into the new system, overcoming challenges related to inventory setup and a general lack of familiarity with the data fields.

“We made a decision early on to begin by going live with functions we could already do with the legacy system,” she said. “We wanted to get the new system right and get familiar with it and then add new functions after the entire staff was comfortable. Management’s commitment to make the system work by devoting the necessary time to tailor the system for our needs was the key to success.”

She said that the first few weeks were bumpy, but since then staff have for the most part settled in and become comfortable with what the system has to offer. They have met their goals, achieving significant improvements in their machine order-to-ship times. Weiser explains that three years ago, Butler’s lead times were 8-12 weeks. Today, the company is able to ship a machine

4-6 weeks after receiving the order.

“We have reduced our engineering time by about a week, and we have seen tremendous improvement in our materials/inventory controls, so that we either have what we need to build the machine or can acquire it quickly,” she said.

Another efficiency gain comes from the system’s ability to better accommodate different currencies. Butler has an office in Geneva, Switzerland, that services European customers. The office works in euros and Swiss francs. In the past, Butler needed to run the European business on one system, while the U.S. business was run on another, which did not support multiple currencies. This created a lot of work when shipping machines to European customers. Butler could not transfer parts from the U.S. to Geneva, so inventories were higher. Financially, they had to consolidate at the end of each period. Epicor takes exchange rates into consideration for various currencies and reports everything in U.S. dollars.

Another benefit is the availability of real-time financial information. The Butler accounting team can now issue preliminary financial statements by noon on the first day of the month, whereas it used to take 4-5 days to prepare statements.

Epicor comes with many standard reports, including a sales gross margin report, which can be run by customer, part, or product group; and a production detail report, which provides information on material, labor, and overhead costs for each job. Additional features allow the accounting team to export data into Excel and then use all of Excel’s features to compile information. Finally, Epicor enables the team to design reports customized to Butler’s business.

Future Modules

Butler is considering several other modules, including a manufacturing execution system (MES) that acts as a control system for managing and monitoring work-in-process on a factory floor. The MES automatically collects information from production machinery to provide an accurate picture of what’s going on in the plant and where improvements can be made. From scrap and downtime analysis to automatic part qualification and rejection, Butler hopes to use the MES data to get the whole story of production in the manufacturing environment.

Implementing ERP

Implementing an ERP system is a major undertaking for a small business. It takes a full commitment by the management team, because people are generally reluctant to change. Encouragement and perseverance are needed to see the implementation through to completion. The right ERP system brings efficiency benefits and provides real-time information that enables manufacturers to make the best decisions. It also helped Butler keep up with the latest management techniques to meet customer demands for fast turnaround times. ASI

For more information, visit www.butlerautomatic.com. Comtec Solutions can be found online at and Epicor is at www.epicor.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!