Formulating Energy-Curable Laminating Adhesives

Laminating adhesives offer a host of benefits for flexible packaging applications.

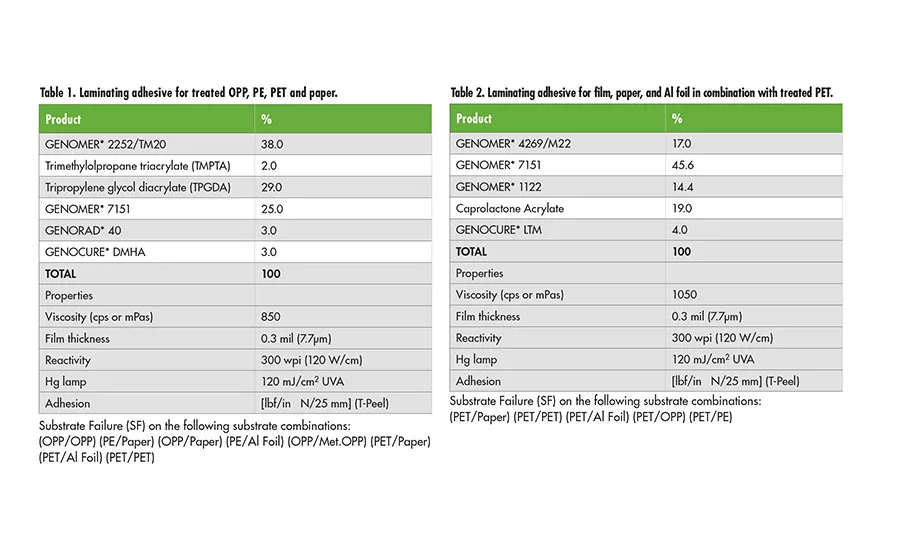

Table 1. Laminating adhesive for treated OPP, PE, PET and paper.

Table 2. Laminating adhesive for film, paper, and Al foil in combination with treated PET.

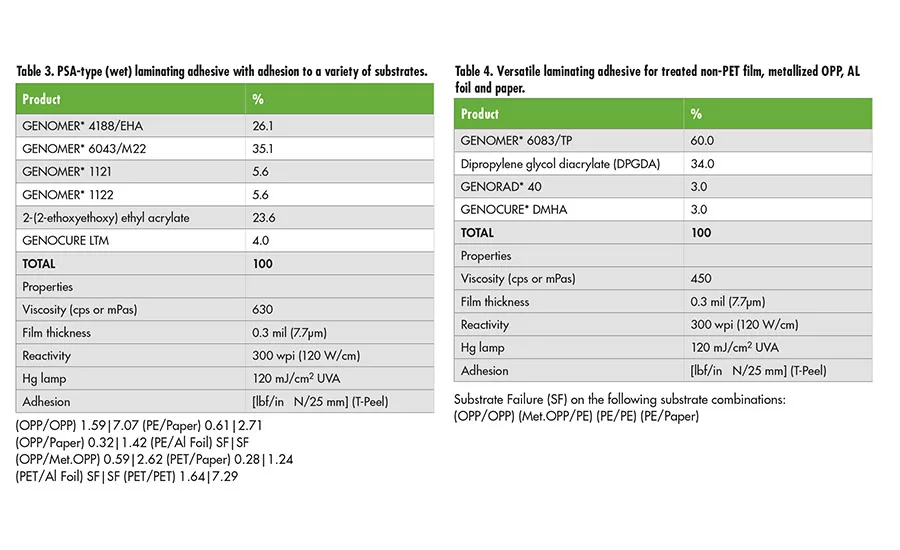

Table 3. PSA-type (wet) laminating adhesive with adhesion to a variety of substrates.

Laminating adhesives (LAs) comprise a relevant and growing segment among energy-curable product markets. Initially regarded as being too expensive and not technically advanced enough for laminating applications, these adhesives have become major players in the converting and packaging industries, particularly in specialty applications.

Laminating adhesives are used in food, medical and industrial packaging. Recently, development work in the realm of food packaging has formed a profitable business base for those willing to implement this technology. The flexible packaging market has seen rapid growth due to the available energy-curable LAs and substrates that can be combined to more effectively package products. New forms of flexible packaging like the stand-up pouch are making products easier to use and more attractive to consumers.

Energy-Curable Benefits

LAs generally bond clear laminate plastic films to other various plastic films, paper or metallic foil substrates. They can be applied by roll coat, flexographic, blanket or screen processes. Depending on the substrate (clear or opaque), curing by UV or electron beam (EB) can offer excellent bond adhesion.

A “dry” type of adhesive offers a non-tacky film that bonds sufficiently to the respective substrates and achieves excellent T-peel properties when cured. However, when adhesion to a particular substrate is difficult or with opaque substrates, EB or pressure-sensitive adhesive (PSA)-type wet laminating adhesives can be necessary.

After curing, a PSA results in a tacky film, which provides a good balance of flexibility, adhesion and cohesion for high peel values. These LAs can be cured prior to lamination.

EB curing uses high-energy electrons to polymerize and crosslink polymeric materials without the use of photoinitiators. This technology reduces curing time and is ideal for opaque substrates due to its penetrating power.

In flexible packaging, UV laminating adhesives have gained popularity in the label industry as an alternative to pressure-sensitive labels. Lamination protects printed graphics against abrasion, chemicals, moisture, scuffing and tearing.

UV/EB laminating adhesives offer the ability to laminate at high speeds and at lower drying and total energy costs. Laminated products can be immediately processed, since there is instant cure and bond development after UV/EB curing. These adhesives are environmentally friendly, easy to handle and provide excellent lamination. In addition, product shipment is possible within hours instead of days compared to traditional water- or solvent-based laminating adhesives.

Starting Point Formulations

The laminating adhesive starting point formulations in Tables 1-4 (pp. 29-30) serve as a basic reference tool for formulators. These formulas can be readily modified to a specific application. This article intends to not only offer the formulator a functional laminating adhesive formulation, but to provide insight into the methods of altering certain properties that will enable a desired endpoint. The relationships between the oligomers, co-resins, and different types of monomers must be well-balanced in order to achieve a functional and optimized laminating adhesive. ASI

For more information, visit www.rahn-group.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!