Advancing Adhesives

Testing the Endurance of Adhesives

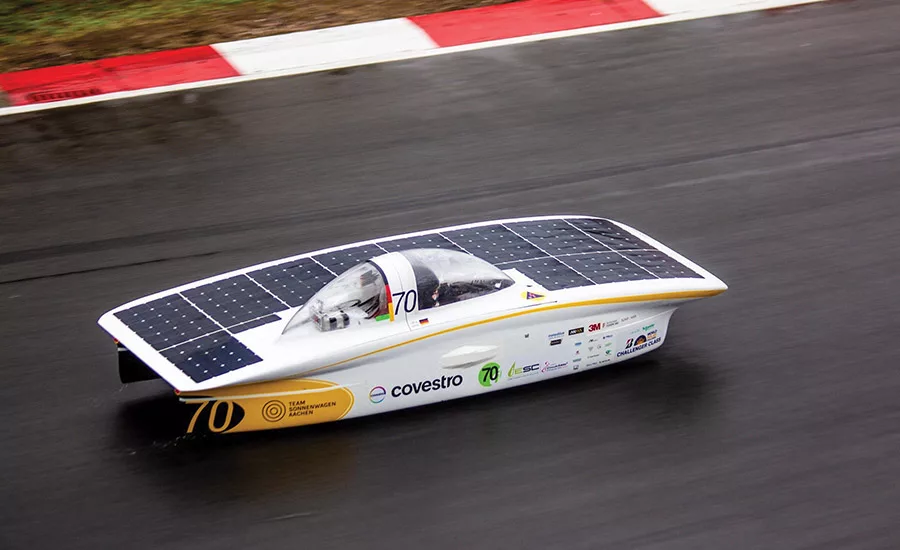

Adhesive bonds will be tested at the Bridgestone World Solar Challenge 2019.

The student team from Aachen uses plastics, composites and metals for the construction of the fast and lightweight Sonnenwagen.

Various two-component adhesives from Sika Automotive will be used in the new Sonnenwagen.

A team of students from RWTH Aachen University and FH Aachen plan to enter their self-constructed, solar-powered electric car in perhaps the world’s toughest solar car race: the Bridgestone World Solar Challenge 2019, which takes place October 13-20 in Adelaide, Australia. After the successful premiere at the previous year’s race, Team Sonnenwagen will attempt for the second time to be the fastest to complete the 3,000-km route without a single drop of fuel.

Covestro will support the project with different materials and technical service, and as the team’s main sponsor. The partners aim to demonstrate that concepts for the future of mobility are already possible today, considering aspects such as lightweight construction, electromobility and photovoltaics.

Adhesive Bonding Solution

The team that wants to be the first to cross the finish line in Adelaide will need a vehicle that is fast and therefore lightweight. Different materials are used to build such a vehicle, including high-quality plastics as well as composite materials and metals. The best method for permanently fastening different substrates together is adhesive bonding; it is also a key technology in the automotive industry.

Joining the parts of a solar car by hand, however, has its own challenges. This includes both preparing the surfaces and improving the adhesive strength of different substrate surfaces. The primary concern, however, is the lasting quality of the bond when the adhesive is dry. The Sonnenwagen will be subjected to extreme conditions on its journey through the Australian Outback: high temperatures, extreme aridity, and constant and sometimes heavy vibrations will put the adhesive to the test.

Tough Adhesives

For its new solar car, the Sonnenwagen Team relies on two-component polyurethane adhesives from Sika Automotive, which are based on the polyurethane raw materials of the Desmodur® and Desmophen® product lines from Covestro. The products from the SikaForce® product line feature excellent mechanical stability and flexibility. They are ideal for bonding complex parts, such as carbon-fiber-reinforced plastics, and are tailor-made for such ultra-lightweight, high-strength designs.

“Thanks to this adhesive, we were able to build this year’s Sonnenwagen in the shape we wanted,” says Severin Kobus, co-chairman of the Sonnenwagen Aachen team. “We used different adhesives—from flexible to highly elastic—in order to meet the requirements in terms of the design, components and substrates.”

“Polyurethane adhesives are a perfect fit for the innovative concepts of future mobility,” says Pascal Obringer, global head of product management at Sika Automotive. “The Sonnenwagen project is an ideal example of the role our adhesives can play in the future.”

Tough Race

The Bridgestone World Solar Challenge is considered the toughest solar race in the world and takes place in Australia every two years. Teams from around the world compete with self-constructed vehicles to be the fastest to overcome the more than 3,000-km route from Darwin to Adelaide powered only by solar energy.

For more information, visit www.covestro.com. Sika Automotive can be found online at www.sikaautomotive.com, and Team Sonnenwagen at www.sonnenwagen.org.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!