Advancing Adhesives

Elastic Strand Bonding without the Use of End-Block Resins

Styrene-isoprene-styrene polymers can be used to eliminate the need for end-block resins in elastic laminate bonding applications.

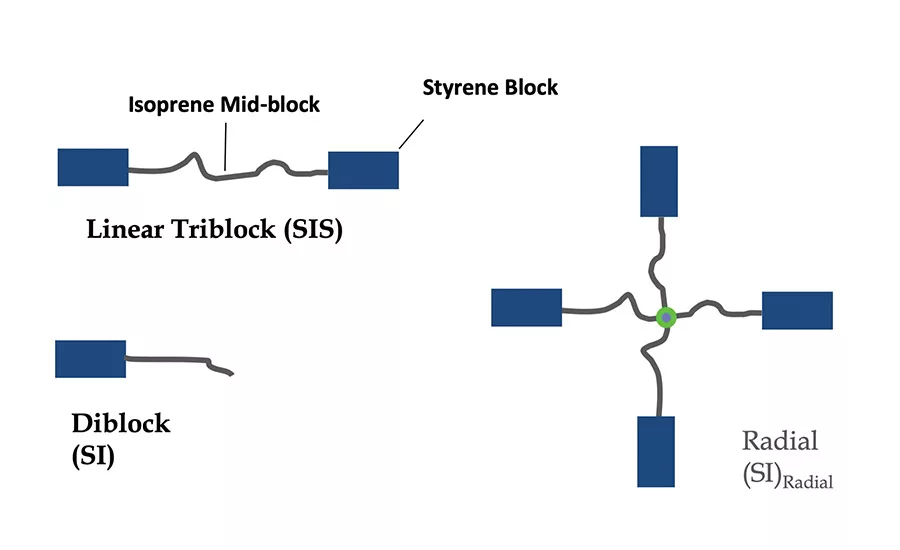

Figure 1. Styrenic block copolymer structures.

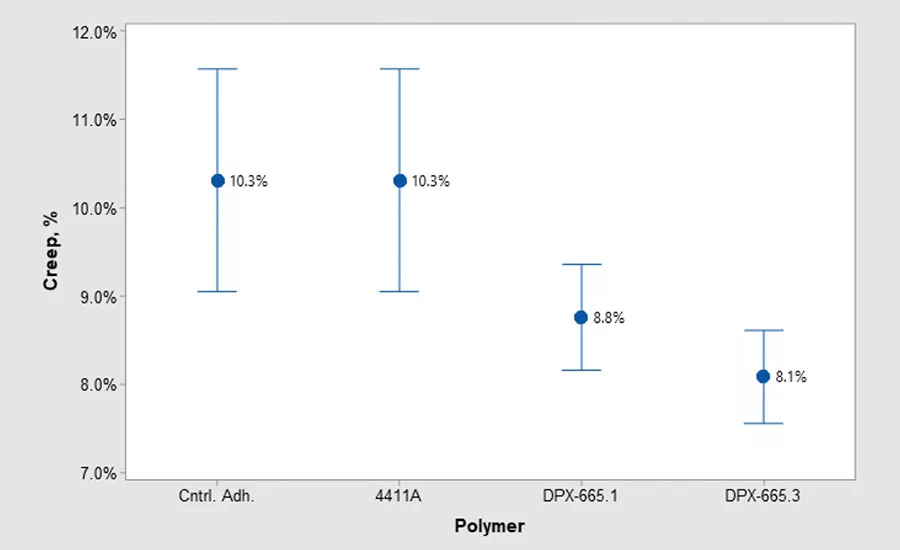

Figure 2. Initial creep (%).

Figure 3. Aged creep results (%).

It is common in the hygiene industry to make elastic laminates by bonding elastic strands using an adhesive. The laminate comprises a layer of non-woven, elastic strands, and a polypropylene back sheet. These three components are held together using an adhesive. Many kinds of adhesives are viable, but hot-melt adhesives are typically used and those based on styrenic block copolymers are favored. Of the types of block copolymers available, styrene-isoprene-styrene (SIS) block copolymers are preferred.

An elastic strand bonding adhesive is typically formulated with several co-ingredients. Along with the polymer, it’s common to add a resin, an oil, an antioxidant, and optionally a wax. Moreover, the resin portion of the formula may consist of two different types of resin. One resin typically is soluble in mid-block, and the second resin is typically soluble in the end block. The mid-block resin provides tack and adhesion, while the end-block resin raises the modulus of the adhesive to make the bond stronger.

By raising the modulus, the end-block resin also helps to hold the elastic strands in place. If the elastic strands slip or creep, the laminate will lose elasticity. Thus, the adhesive must hold the laminate together and prevent the bonded elastic strands from creeping. A typical elastic strand bonding adhesive comprises 20-55% polymer, 40-65% mid-block resin, up to 35% end-block resin, 5-30% oil, optionally less than 5% wax, and no more than 3% of an antioxidant(s). Specific examples of adhesive formulae are provided in Table 1.

End-block resins are limited in supply, high in odor, and tend to reduce adhesion. Thus, the elimination of end-block resins would be useful. SIS polymers can be used to eliminate the need for end-block resins. Commercially available SIS polymers have three separate structures: triblock, diblock, and radial. Figure 1 provides examples of these structures. A triblock polymer comprises a block of polystyrene (commonly referred to as the “end-block(s)”), followed by a block of polyisoprene (commonly referred to as the “mid-block”), and followed by a second block of polystyrene. Diblock is best thought of as one-half of a triblock. To make a radial polymer, first the diblock is polymerized and then a multi-functional coupling agent is used to form the radial structure. Typically, a radial polymer has between three to four arms. The polymer structure is important in eliminating end-block resins.

High-styrene polymers (≥ 36% polystyrene) and radial polymers are good choices for eliminating end-block reinforcing resins. Examples of high-styrene and radial polymers are provided in Table 2. The high-styrene polymer increases the modulus of the adhesive and thus prevents the elastic strands from creeping. Radial polymers have limited molecular mobility, which reduces the ability of the adhesive to move and prevents the elastic strands from creeping. Styrenic block copolymers organize themselves into a polystyrene-polyisoprene matrix. The matrix comprises separate domains of polystyrene and polyisoprene. One can think of the styrene domains as anchors that prevent the polymer chains from moving. A triblock (or linear) polymer has two anchor points. A radial polymer, however, has three to four anchor points. It is the increased number of anchor points that makes it more difficult for the radial polymer to move, thus limiting molecular mobility.

Adhesive Performance

The amount of initial creep for the laminate should be less than 25% but preferably between 8-12%. Figures 2 and 3 show the initial and aged creep performance for the adhesive formulae listed in Table 1.

Figure 2 shows the initial creep results for the adhesives based on the polymers listed in Table 2, using the adhesive formulae listed in Table 1. Additionally, the adhesives were compared to a control adhesive. For all the polymers tested, the adhesives met the creep requirements and compared favorably with the control. Vector® 4411A had similar creep values compared to the control, but DPX-665.1 and DPX-665.3 had lower creep values than the control and Vector 4411A.

Figure 3 shows the aged creep results for the adhesives listed in Table 1. As before, the adhesives were compared to a control adhesive. After aging, the creep should be less than 25% and preferably between 12-18%. On average, the adhesives in Figure 3 meet the creep requirements.

Unlike the results in Figure 2, however, Figure 3 shows greater differences between the samples. Adhesives based on Vector 4411A did not perform as well as adhesives based on DPX-665.1 or DPX-665.3. In addition, 4411A performed worse than the control adhesive. On the other hand, DPX-665.1 performed better than Vector 4411A, but not as well as the control. The best creep result came from the adhesive based on DPX-665.3. It performed better than the control, Vector 4411A, and DPX-665.1.

Multiple Options

The data presented indicate that it is possible to formulate elastic strand bonding adhesives without the use of an end-block reinforcing resin. In addition, it shows that both approaches are useful. Either a high-styrene polymer or a radial polymer will work to make an acceptable elastic strand bonding adhesive without an end-block reinforcing resin. Radial polymers, however, seem to provide better performance overall.

For more information, contact the author at (225) 309-0229 or paul.dalley@tsrc-global.com, or visit www.tsrc.com.tw.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.webp?height=200&t=1704834340&width=200)