EVONIK: Synthetic Silica for Coatings Formulations

Evonik reports that variations in the wet reaction process conditions enable the control of many aspects of final coatings formulations, such as pH, surface area, pore volume, and other structural or morphological effects.

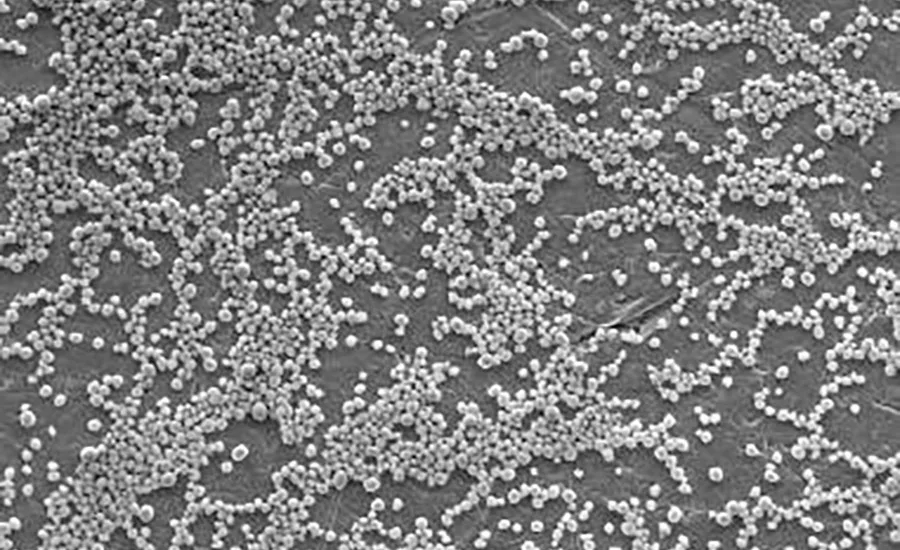

The Coating Additives business line of Evonik recently introduced SPHERILEX® silica wet chemistry technology, with three new products: SPHERILEX DP-0111, SPHERILEX DP-0112, and SPHERILEX DP-0115. According to Evonik, the manufacturing process produces material with a unique spherical particle morphology, providing non-traditional silica benefits to coatings. Variations in the wet reaction process conditions enable the control of many aspects of the final product, such as pH, surface area, pore volume, and other structural or morphological effects.

In coatings, precipitated silica is widely known as a superior matting agent. Its functional characteristics, however, are eventually determined by many differentiators like particle size, size distribution, particle morphology, and more. In other words, the ability to control these aspects enables formulators to control the properties and benefits of the precipitated silica.

Recent process advancements at Evonik have reportedly produced a novel class of synthetic silica with:

- unique spherical particle morphology

- narrow particle distribution

- very low surface area and porosity

In addition, regulatory concerns and other challenges have resulted in a decreasing array of available materials from which to formulate. Solvents, for example, soften polymers and allow them to flow more freely to surround and wet the pigment particles in a coating, thereby enhancing the binding ability of the binder. As the availability of these solvents diminishes in the marketplace due to requirements to reduce VOCs, formulators must seek new ways to minimize the binder demand of the solids in their formulations.

Evonik reports that its new SPHERILEX technology addresses these challenges in coatings formulations and offers a new range of functional silica and silicate products with unique performance profiles that help formulators realize new value in synthetic silica technology. Additional details are available at www.coating-additives.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.webp?height=200&t=1654641653&width=200)