Wacker Increases Global Production Capacity for Silicone Rubber

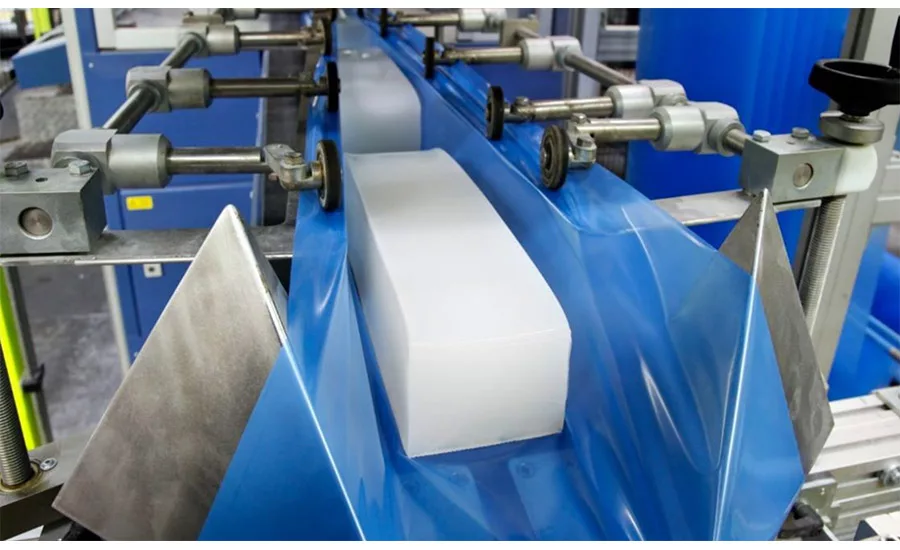

Wacker will be continuously expanding its production capacities for silicone rubber specialties in the next few years. (Photo courtesy of Wacker.)

To meet growing demand for silicone rubber, Wacker Chemie AG is accelerating the expansion of its production capacities. The company reports that investment projects to this end are either in the planning stage or are nearing completion. Significant capacity expansions for liquid silicone rubber (LSR) will be available in the second half of this year and will come into full effect in 2023.

Increasing production volumes for high-consistency rubber (HCR) are also scheduled. With expansion measures at several other sites, Wacker will gradually increase its capacities for HCR and LSR grades significantly in the next few years. Over €100 million (approximately $106.8 million) has been earmarked for this capacity boost.

“WACKER returned to a growth trajectory last year,” said Christian Hartel, CEO. “We finished 2021 with record sales and strong earnings—despite headwinds from raw material and energy prices. We want to maintain this momentum and are charting our course for accelerated growth going forward. This is also true for our specialty chemicals business.”

Wacker’s growth campaign will also focus on silicone rubber specialties. “Silicones are high-performance materials,” said Robert Gnann, head of the Wacker Silicones business division. “They are essential for state-of-the-art product solutions and are among the innovation drivers in key industrial sectors such as automotive, electronics and medical. Silicone rubber is strategic for us. As the world’s second largest silicone manufacturer, we are committed to supporting this dynamic growth even more strongly in the future.”

The availability of liquid and high-consistency silicone rubber will benefit from several expansion measures in the coming years. Wacker expects additional LSR capacities in the second half of this year due to several capacity expansions at its production site in Burghausen, Germany, which will be complete at the end of the year. New capacities will also be installed at the company’s U.S.-based production site in Adrian, Mich., to better serve the North and Central Americas market locally from next year forward.

The company reports that substantial capacity expansions are also planned for high-consistency rubber grades, starting with a new production site in Panagarh, India, which will start production shortly. Additional HCR capacities will be available early next year at Wacker’s sites in the Czech Republic (Pilzen) and in Japan (Tsukuba).

Silicone rubber consists essentially of silicone polymers and fillers. The polymers are crosslinked with suitable reactants to produce three-dimensional structures that convert the fluid or ductile rubber compound into an elastomer. Silicone rubber is generally classified as high-consistency rubber (HCR), room-temperature vulcanizing rubber (RTV) or liquid silicone rubber (LSR). Silicones are easy to process and, once crosslinked, feature excellent mechanical properties that remain unchanged over a wide temperature range.

Visit www.wacker.com to learn more.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.webp?height=200&t=1709670950&width=200)