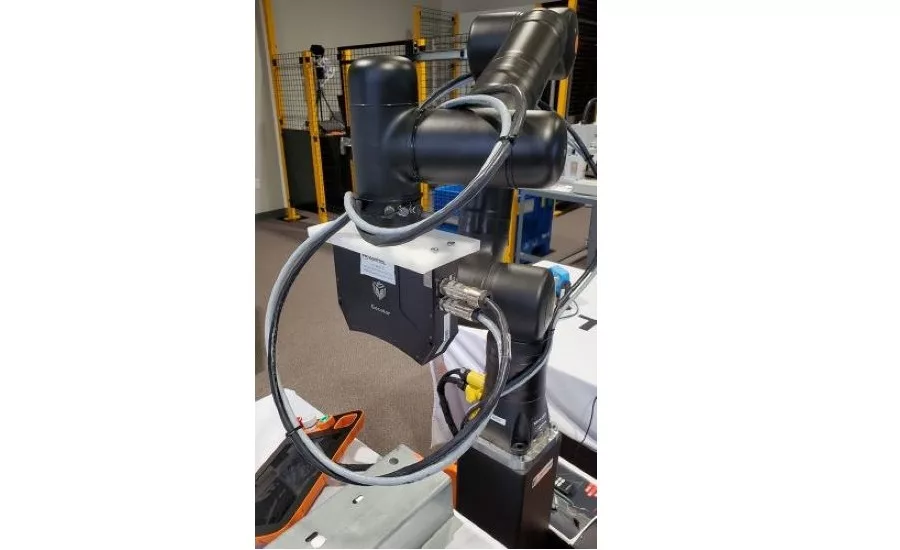

Industrial Control Bolsters Kassow Robots’ Solutions and Education Platform

Courtesy of Kassow Robots

Kassow Robots, a developer of 7-axis cobots for machine tending, material handling, and related applications, has partnered with Industrial Control in Zeeland, Michigan, a factory automation distribution specialist. Many applications in manufacturing still require a human touch. The combination of Kassow Robots’ KR series of 7-axis cobots and Industrial Control’s solutions allows humans and robots to work together to efficiently complete repetitive tasks and those that require the highest accuracy, such as quality assurance.

The partnership can advance automation manufacturing and help close the skills gap by providing engineers, technicians, and operators valuable experience through Industrial Control’s training and Kassow Robots’ flexible and easy-to-use software programming.

“Adding Kassow Robots’ lightweight cobots to our portfolio offers terrific opportunities for our customers,” said Mark Ermatinger, CEO of Industrial Control. “The cobots are easy to use and quick to integrate for manufacturing operations in the medical, semiconductor, and electronics industries. The KR series’ payload, reach, speed, and ability to work safely with humans can help increase automation adoption at both small- and medium-sized companies.”

The 7-axis cobots provide a reach of about 3–6 ft (850–1800 mm) and payloads around 11–40 pounds (5–18 kg) to automate a variety of tasks. The 7th axis enables continuous dispensing, welding, and material removal applications regardless of access angle, without the need to reorient the arm.

Learn more at www.kassowrobots.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!