Home » hot melts

Articles Tagged with ''hot melts''

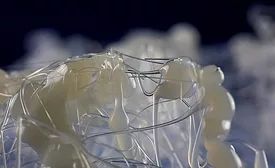

As market drivers accelerate the adoption of polyurethane reactive hot melt adhesives away from solvent-borne solutions, the use of polycaprolactone technology in reactive hot melt adhesive applications is examined.

Read More

Arkema Discusses Integrated PSA Offering

Tim Pione outlines Arkema’s position in pressure-sensitive adhesives and what the company has planned for the future.

July 11, 2023

Creating PU Adhesives Using the Mass Balance Method

Raw materials supplier and adhesive manufacturer partner to create adhesive using the mass balance approach.

June 14, 2023

Hot Melt Adhesives Market Grows amid Supply Chain and Raw Material Challenges

World demand for hot melt adhesives expected to grow in multiple applications, latest Smithers insight reveals.

April 12, 2023

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.webp?height=168&t=1704834340&width=275)