Meter/Mix/Dispense

Dispensing Systems for Automotive Speaker Production

Dispensing systems help manufacturers of automotive speakers and headphones master required precision and high cycle rates with ease.

January 21, 2023

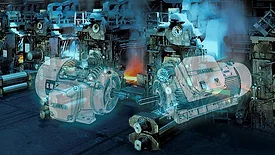

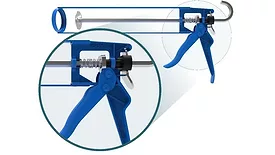

Innovative Process for Sealing Contours Protects Sensitive Components

New dispensing processes allow for more precise application of liquid seals in assembly of automotive components.

January 16, 2023

Adhesive Dispensing for Medical Device Assembly

Many manufacturers of medical devices, point-of-care and near-patient testing products, and medical wearables are reassessing and upgrading their assembly fluid dispensing capabilities.

December 20, 2022

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.webp?height=168&t=1672772974&width=275)