Adhesives & Sealants Industry Top Stories

Net revenue of $770 million increased 37% compared with the third quarter of 2017.

Read More

Tape Talk

Developments in Plasma and Flame Surface Treaters for Improving Adhesion

Ongoing advancements with plasma and flame surface treaters are expanding the systems’ use in a growing number of industries.

October 1, 2018

Henkel Marks 142 Years in Business

The company reportedly continues to grow as an innovative global leader in brands and technologies.

September 27, 2018

Dow Announces Plans for Silicone Resin Plant

The new facility is expected to come online in 2021.

September 24, 2018

Record Attendance at FEICA European Adhesive & Sealant Conference

600 participants from 35 countries attended the 2018 FEICA Conference and Expo.

September 24, 2018

Market Trends

Auto Adhesives Vroom Ahead

Adhesives adoption in the automotive sector is projected to drive a $7 billion market by 2022.

September 21, 2018

Henkel to Build Global Innovation Center for Adhesive Technologies

Once completed, the facility will house more than 350 employees.

September 18, 2018

Advancing Adhesives

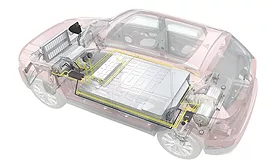

Sealing Solution for Electric Vehicles

Structural adhesives for battery pack assemblies in electric vehicles help ensure long-life components operation.

September 1, 2018

Case Study

Setting Sail with Structural Adhesives

The ETS Rafale II student team built a carbon epoxy C-Class hydrofoil catamaran using Scott Bader structural adhesives.

September 1, 2018

Waterborne Acrylic PSA Technology with High-Temperature Performance

A new waterborne technology offers excellent adhesion properties and high temperature performance.

September 1, 2018

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing