Equipment Handbook

Are you sure you want to leave before submitting your RFP?

A comprehensive directory of suppliers and manufacturers of machinery and equipment for adhesive and sealant manufacturing, formulation, and testing.

Excelitas Technologies

Company Profile

Excelitas Technologies

7425 N.E. Evergreen Pkwy.

Hillsboro,

OR

97124

United States

Phone: (503) 439-6446

(800) 668-8752

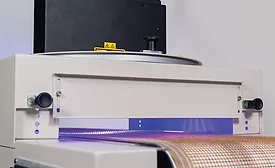

Excelitas offers customers the full spectrum of solutions from UV to IR, supporting a wide range of applications. As a single source provider, the Excelitas portfolio includes UV lamps and systems, UV LED spot and area curing systems, UV microwave, Infrared emitters and systems, and medium pressure UV lamps.

Product Categories

Articles

EXCELITAS TECHNOLOGIES CORP.: Next-Generation Spot UV Curing System

The system features proprietary OmniCure closed-loop feedback control technology, which automatically monitors and maintains the optical output for a repeatable curing process.

November 30, 2021

Excelitas to Highlight Curing Systems for Medical Device Manufacturers at MD&M Minneapolis

MD&M Minneapolis will take place November 3-4 at the Minneapolis Convention Center.

November 3, 2021

Excelitas Opens New Qioptiq Photonics Plant in Germany

The plant expands the company’s capacity for the assembly of optomechanical systems and components for the semiconductor industry.

October 5, 2021

Excelitas Completes PCO Acquisition

The acquisition expands Excelitas’ technological scope and its geographic footprint in Europe, North America, and Asia.

September 14, 2021

Excelitas to Highlight UV Curing Systems at MD&M West

MD&M West will be held August 10-12 in Anaheim, Calif.

August 10, 2021

Excelitas Announces Agreement to Acquire PCO

PCO is the latest in a series of strategic acquisitions by Excelitas Technologies.

July 1, 2021

Excelitas Technologies Celebrates Milestone

Since being established as an independent company spun out of Perkin Elmer in December 2010, Excelitas reports that it has enjoyed greater than three-fold growth in both revenue and headcount.

December 4, 2020

Excelitas Technologies to Showcase LED UV Curing Systems at RadTech UV+EB 2020

In addition to Excelitas’ booth at RadTech, Marvin Ruffin, business development manager, will present a session entitled “Preventing Hospital-Acquired Infections with UVC LEDs” during the co-located 2020 IUVA Americas Conference UV for Healthcare Applications Track.

March 3, 2020

Manufacturing Conversion: Transitioning from Conventional UV to LED Curing

While the process steps in a UV LED manufacturing conversion are slightly more involved than a direct-swap mercury replacement, the benefits are often significant and well worth the time and effort.

February 10, 2020

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.webp?height=168&t=1702518831&width=275)