Home » Keywords: » QC/QA management

Items Tagged with 'QC/QA management'

ARTICLES

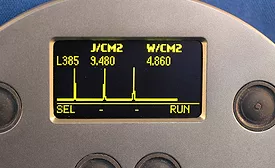

Understanding and Measuring UV LEDs

It is important to consider the variables associated with the LED source and proper measurement tools in order to understand, maintain, and control the adhesive curing process.

October 6, 2021

Going Above and Beyond OEM Testing Requirements

The best practice in testing procedures involves incorporating additional quality control and testing standards beyond those required by OEM partners.

October 9, 2020

SOCMA Announces 2019 Performance Improvement Award Winners

Nation Ford Chemical and VanDeMark Chemical will receive SOCMA’s highest honor—the Gold Performance Improvement Award.

November 22, 2019

Happy Manufacturing Day!

The second annual Manufacturing Day will be held today throughout the U.S.

October 4, 2013

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing