Moisture-Cure Polyurethane Adhesives: A Quiet Force in Industrial Innovation

Image courtesy of Future Market Insights Inc.

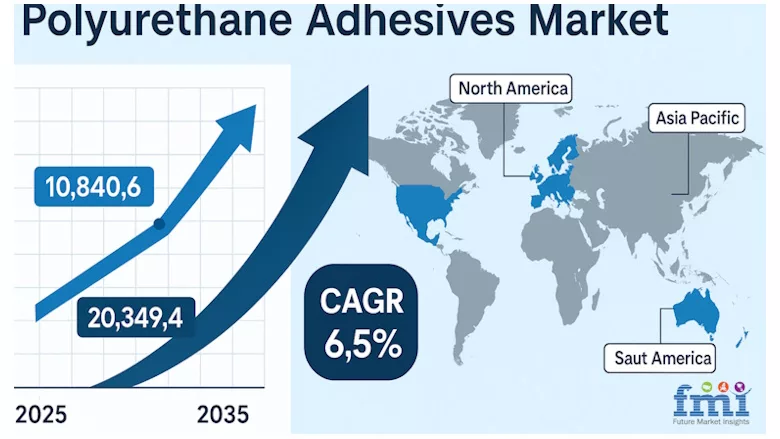

A new report from Future Market Insights Inc. reveals that the global polyurethane adhesives market is gaining strong momentum, valuing the market at over $8 billion in 2024 and projecting it to grow steadily through 2035. While familiar applications in automotive assembly, woodworking, and flexible packaging remain central to the market narrative, a quieter but transformative development is unfolding in high-stress industrial environments. Within this shift, moisture-cure polyurethane adhesives are emerging as a powerful yet underrecognized solution — outperforming conventional adhesives where durability and flexibility are critical.

Moisture-Cure Polyurethan Adhesives: A Silent Performer

Moisture-cure polyurethane adhesives, often referred to as single-component PU adhesives, cure by reacting with ambient humidity. This mechanism eliminates the need for pre-mixing or external catalysts, reducing complexity during application. Unlike traditional two-part systems that require precise ratios and limited working times, moisture-cure adhesives provide greater flexibility and ease of use in dynamic industrial environments.

Future Market Insights reports that these adhesives exhibit exceptional performance in extreme conditions, such as high humidity, intense heat, and chemical exposure, making them ideal for sectors where adhesive failure is not an option. In particular, their elongation capabilities and resistance to thermal cycling give them a distinct advantage over epoxies and acrylics, which tend to become brittle under similar stresses.

Reliability in Extreme Conditions

In heavy-duty sectors like mining, renewable energy, and transportation infrastructure, substrates are subjected to constant movement, vibration, and environmental stressors. Traditional adhesives such as solvent-based epoxies or hot-melts often crack or delaminate under such conditions. In contrast, Future Market Insights reports that moisture-cure polyurethane adhesives form highly elastic bonds capable of absorbing shock and maintaining adhesion over time.

"Despite limited visibility in reports, moisture-cure PU adhesives are driving innovation in high-stress sectors, signaling untapped growth and strategic investment potential,” explained Nikhil Kaitwade, associate vice president at Future Market Insights.

A compelling example lies in the offshore wind energy industry, where polyurethane adhesives are increasingly used to bond structural components of wind turbine blades. These blades must endure wind shear, saline air, and UV exposure — conditions where conventional adhesives can degrade. Moisture-cure PU adhesives, however, retain both strength and flexibility.

Similarly, in underground mining equipment, metal-to-rubber bonding is critical. Moisture-cure polyurethanes, known for their ability to bond dissimilar materials, are used to affix rubber liners to steel components, reducing wear and vibration damage. In such applications, failure isn't just inconvenient — it can lead to substantial operational downtime and financial loss.

Mastering the Art of Bonding Dissimilar Materials

A major strength of moisture-cure PU adhesives is their ability to bond dissimilar materials without compromising structural integrity. Industries increasingly rely on hybrid components — metal to composite, plastic to rubber, or glass to metal — especially in efforts to reduce weight while increasing durability.

For instance, in the rail industry, composite panels are replacing heavier steel sections to improve fuel efficiency. Moisture-cure polyurethane adhesives provide the elasticity needed to accommodate differential thermal expansion between these materials, something rigid adhesives like epoxy cannot handle without risk of fracture.

The automotive sector also benefits from this versatility. In electric vehicle (EV) battery assemblies, where lightweight materials and thermal regulation are critical, these adhesives serve dual functions—securing components and insulating against heat. Their long open time and rapid curing upon exposure to humidity allow for both manual and automated assembly processes, enhancing manufacturing efficiency

A Greener Path Forward

As environmental priorities reshape industrial decision-making, the polyurethane adhesive landscape is adapting. Moisture-cure formulations are evolving with the introduction of bio-based polyols, sourced from soy or castor oil, to reduce reliance on fossil fuels.

Furthermore, advancements in low-VOC and isocyanate-free technologies are addressing health and regulatory concerns, particularly in Europe and North America. These innovations are designed to maintain industrial-grade performance while aligning with stricter safety and environmental standards.

Major players like Henkel and Sika have launched next-generation moisture-cure PU adhesives that meet LEED and green building certification standards. In infrastructure applications such as bridge retrofits and tunnel sealing, these eco-conscious adhesives are increasingly specified by contractors and public agencies aiming for sustainable construction.

Unlocking an Overlooked Opportunity

Despite their technical merits and growing relevance, moisture-cure polyurethane adhesives remain underreported in mainstream market analyses. Overshadowed by larger categories like automotive body adhesives or footwear bonding, their critical role in industrial applications often goes unnoticed.

But as industries place greater emphasis on resilient, versatile, and environmentally sustainable materials, these adhesives are moving from the margins to the mainstream. Their ability to thrive in extreme conditions, bond complex assemblies, and align with green goals positions them as a key enabler of next-generation manufacturing and infrastructure.

Recognizing their potential requires a more detailed and informed market perspective — one that acknowledges their unique capabilities and accelerating adoption. With continued innovation and growing awareness, moisture-cure polyurethane adhesives are poised to play a central role in the evolving industrial adhesive landscape.

Explore the full market report at www.futuremarketinsights.com/reports/polyurethane-adhesives-market.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!