Why Measure Surface Energy?

Measuring surface energy is critical to the successful application of adhesives, coatings, and inks.

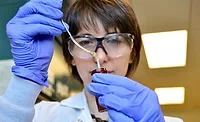

Dyne Pens and inks.

Surface energy is crucial in determining the wetting behavior of liquids on solid surfaces. Generally, surfaces with higher surface energy are more easily wetted by liquids, resulting in better spreading, while surfaces with lower surface energy are more likely to repel liquids. A prerequisite to any adhesion and bonding is wettability, so measuring surface energy is critical to the success in the application of adhesives, coatings, inks, and more. Kevin Brownsill, head of Technical and Learning at adhesives and sealant supplier Intertronics, and Alison Fox, Dyne sales manager at Dyne Testing, an Intertronics brand, answer questions about why manufacturers should measure surface energy.

Why is surface energy important?

Alison Fox: Different solids have different surface energy depending on their molecular makeup. For example, polytetrafluoroethylene (PTFE) has a very low surface energy, and metals typically have a high surface energy. The surface energy of a substrate can also be affected by roughness and contamination. Surface energy will affect liquid flow across the substrate and can influence, for example, the formation of homogenous thin coatings and the way that fluids react with objects placed in the human body in biomedical applications.

Kevin Brownsill: The successful application of adhesives, coatings, inks, and other materials where adhesion is important is highly dependent on the wettability of these materials to the target substrate. If the liquid behaves like water on a greasy plate, forming discrete balls rather than a film, then it is easy to see adhesion problems ahead.

Why is wetting necessary?

Brownsill: For bonding or printing to be a success, the surface energy of the substrate must be higher than that of the liquid so that wetting can occur — the liquid forms a contiguous film on the surface, rather than the liquid beading up or retracting from the surface. So, we need to understand the relationship between the surface energy of the substrate and the surface energy or tension of the liquid. Many modern plastics have low surface energies that make bonding a challenge, because they are lower in value than the adhesive or ink. Another issue may be surface contamination, like oils, greases, or release agents, which can influence surface energy and inhibit wetting.

Fox: Surface measurement technologies help identify the cause of poor wettability, so that manufacturers can optimize material choice or the surface preparation process to eliminate adhesion issues. We can measure physical properties of the substrate and the surface tension of the liquid; understanding those is important for that bonding mechanism.

How and when do you measure surface energy?

Brownsill: For qualitative and fast testing, dyne inks are a cost-effective method that can be used for on- or off-the-line testing. The inks have specific surface tension, measured in mN/m, or dyne/cm, often known as "dynes." When a dyne ink is applied to a substrate, the ink will either form a continuous film on the surface or pull back into small droplets. If you apply a 38 dyne ink to a substrate, and the ink stays as a film for three seconds, the substrate has a surface energy of at least 38 dyne/cm.

Dyne inks are predominantly supplied in a special pen, which makes them very convenient and portable. A manufacturer can take a component/material off the production line and test it quickly for its surface energy — so for example, confirming that a polyethylene film has been surface treated prior to printing. By using a range of Dyne Pens of various dyne levels, the surface energy of a substrate can be determined to a narrow range.

Fox: At the other end of the scale are measuring instruments like tensiometers, which are used to measure the surface tension of liquids. It can also measure other properties, like contact angle. The wetting behavior of a liquid on a solid surface is directly related to the contact angle and surface energy, where a lower contact angle indicates higher surface energy and better wetting, while a higher contact angle suggests lower surface energy and poorer wetting. A good example of this kind of instrument is the Biolin Scientific Theta range. A drop of liquid is dispensed onto a substate and viewed from the side with a high-resolution camera. This is analyzed with sophisticated, user-friendly software. These instruments are predominantly used off-line to give accurate and repeatable quantitative measures of contact angle, and therefore wetting.

Optical tensiometers like the Theta range are used in production quality-control centers, product development and research laboratories, and test houses. With contact angle measurement you can compare solids and liquids with surface treatments to ascertain the most effective.

How can surface energy be improved?

Fox: First, manufacturers should understand what surface properties are needed to obtain the ideal conditions for adhesion. If you’ve got a clean, dry, dust-free and non-porous surface, you’ve got the first step to good wettability. For some applications, the surface can be cleaned with an isopropyl alcohol wipe to ensure there are no oils or greases. For more critical applications, understanding the cleanliness of the substrate is beneficial. For example, on metal substrates, the SITA CleanoSpector is a popular and easy-to-use handheld non-destructive metal-cleanliness test instrument used for measuring organic contamination such as oil, grease, coolants, release agents, and cleaning fluid. This can indicate the need for a more effective cleaning process or highlight a poorly functioning cleaning process.

Even if you have a clean substrate, you will still have wetting and bonding problems if that substrate has a low surface energy or is a non-polar surface. Many common plastics, such as polyethylene and polypropylene, have non-polar surfaces and low surface energy. Some form of additional surface treatment can help; this includes flame treatment, corona, or plasma.

What is plasma surface treatment?

Brownsill: Application of plasma to a surface can clean at a molecular level and increase surface energy — activating the surface ready for bonding. For example, at Intertronics, we have used atmospheric plasma on a polyethene surface. Untreated it had a surface energy in the low 30s mN/m, but treated it had a surface energy of ~55 mN/m, therefore making it bondable with an adhesive with a surface tension in the 40/45 mN/m range.

Plasma can modify and functionalize surfaces to prepare them for adhesive bonding, varnishing, or printing without altering the bulk properties, or marking or discoloring the treated part. In a process known as surface functionalization, plasma treatment causes the generation of polar oxygen groups on the substrate’s surface, which can act as bonding anchors by forming covalent bonds with molecules in an adhesive to increase bond strength.

Atmospheric pressure plasma treatment is a versatile and efficient method for surface modification, widely used in industries ranging from automotive to biomedical for improving surface properties without altering bulk material characteristics. These devices can often use compressed air, or sometimes specific gas mixtures for special applications. For larger scale fast production, manufacturers can opt for technology such as the Relyon plasmabrush PB3, which can be integrated into automated, continuous production processes.

There is also a range of cold atmospheric plasma devices on the market. The Relyon piezobrush PZ3 handheld device is a good choice for R&D, pre-production, or medium-volume work due to its small size and maneuverability, while a variant, the PZ2-i can be mounted onto a robot for automated or semi-automated applications.

For assistance in measuring surface energy and to find out which application is most suited to your production needs, visit Dyne Testing’s website at https://dynetesting.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!