Advancing Adhesives

High-Performance Bonding

New adhesives offer manufacturers solutions to reduce weight and gain fuel efficiency.

As vehicle manufacturers worldwide look to reduce weight from their cars and trucks in order to boost fuel economy and reduce emissions, they must set aside the mindset that has dictated traditional material and process choices and instead consider new and emerging technologies. This includes selecting adhesives and other joining options. Each car today contains, on average, 15 kg (~ 33 lbs) of adhesives―and this amount will likely increase in the future. Components such as instrument panels, fenders, windshield wipers, gears and the cross members on frames are all kept in place by various types of adhesives.

Today, adhesive technology is gaining greater scrutiny because automakers increasingly are turning to polymer-based composites to replace steel and aluminum, which creates a growing need to find effective ways to bond these types of mixed materials. In some applications, adhesives need to provide structure and rigidity; in others, they need to be flexible and pliable―all while providing a nearly unbreakable bond.

While initially it might seem counter-intuitive, testing has shown that adhesive bonds are more stable than welded joints. This stability makes them viable options in demanding applications, such as on frame cross members. Thus, more vehicle makers are turning to adhesive bonding instead of the more traditional joining methods of welding and riveting. Adhesives also can help to seal scratches and joints while also reducing noise.

A major challenge for hybrid multi-substrate systems designers is how to overcome the different coefficients of thermal expansion (CTEs) when creating bonds that must last for many years. The market needs an adhesive that offers both high strength and high elasticity.

To answer this need, Henkel has developed Loctite UK 2015, which is based on two-component polyurethane technology. This adhesive is suited for use on structural body parts, regardless of whether they are made of fiber-reinforced plastics, e-coated steel or e-coated aluminum.

Composite Springs

An innovative example of where plastics composites are taking over from steel was recently implemented by Volvo for use in its new crossover SUV model, the XC90, as well as in its premium V90 estate and S90 models and the XC60, V60 and S60. Henkel partnered with Austrian automotive composites maker Benteler-SGL to redesign the vehicles’ rear suspensions.

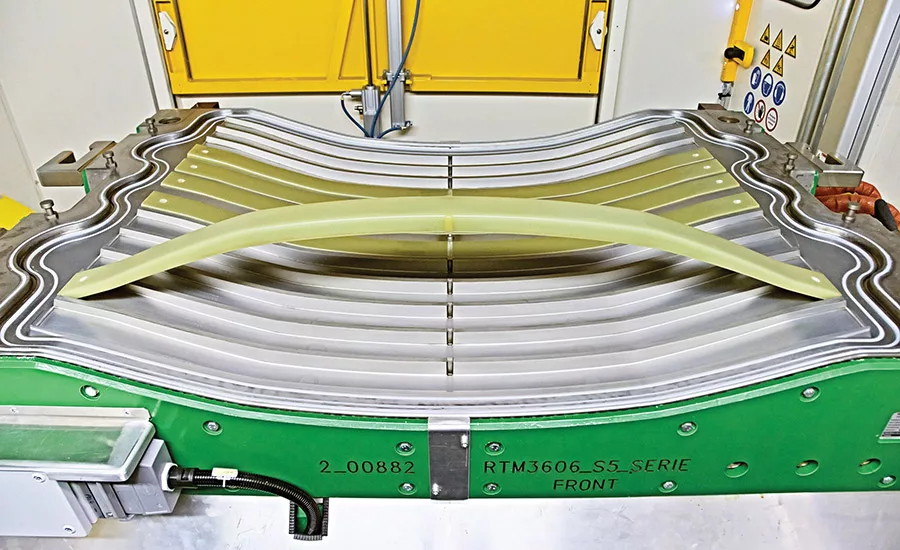

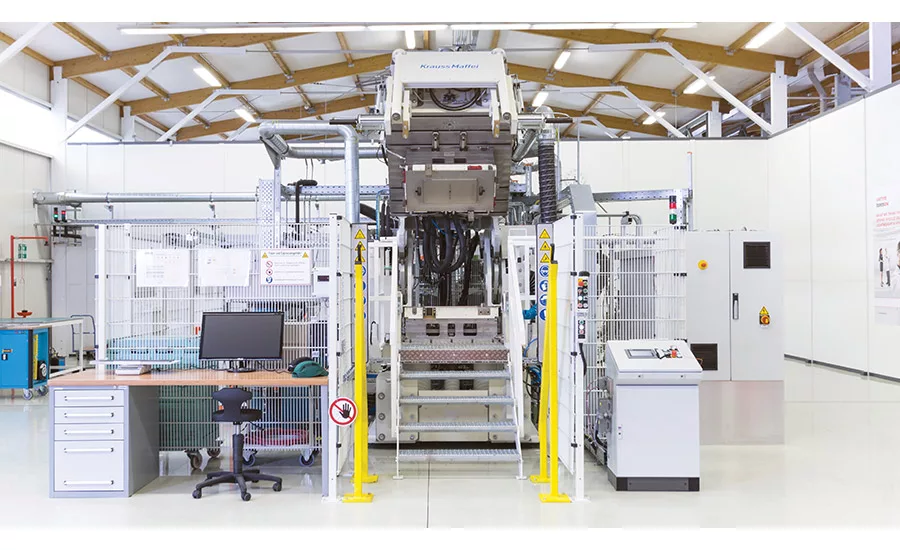

The aim was to replace the usual helical springs that are mounted on the rear axle. This was accomplished by using high-pressure resin transfer molding (HP-RTM) to produce lightweight leaf springs made from an advanced, glass fiber-reinforced polymer composite material.

The transverse leaf spring enables a more compact axle design than with the bulky helical steel springs it is replacing. The transverse leaf spring allows the elimination of the coil springs, which means the axle protrudes less into the trunk area, leaving more loading space. In addition, the new design provides a smoother ride and improved NVH (noise, vibration, harshness) behavior.

Even more important is that the composite leaf spring offers significant weight savings compared with its metallic counterparts. The new axle system weighs 4.5 kg (~ 10 lbs) less than the conventional helical spring construction.

Henkel’s Loctite MAX 2 two-component polyurethane composite matrix resin system enabled Benteler-SGL to develop these innovative leaf springs. The resin system has very low initial viscosity, which enables fast injection of the resin into the mold and excellent penetration between the tightly packed reinforcing glass fibers.

Once injected into the mold, the matrix resin cures quickly for demold times as low as 1 min/part. The production system installed at Benteler-SGL, which uses a multi-cavity tool, is designed for a production output of more than 100,000 pieces per year. Last year, Benteler-SGL produced close to 100,000 composite leaf springs; the company is projecting a figure of around 200,000 for 2017. ASI

For more information, visit www.composite-lab.com. Volkswagen can be found online at www.vw.com, and Benteler’s website is www.benteler.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!