Designing Adhesives for Long-Wear Skin Contact Applications

Identifying the right skin-contact adhesive for long-wear applications can be challenging.

The medical adhesive market continues to show strong growth year over year, with an annual growth rate of over 4%. Specific segments contributing to that growth are related to health and wellness, such as monitoring devices and fitness trackers. Many of the growing segments represent longer wear. While the definition of “long wear” can and does vary depending on the application, a typical working definition is longer than 1 week; many medical products companies are targeting up to 3 weeks for new applications.

Design Challenges

Designing for long wear can be challenging. Typical skin contact constructions consist of multiple layers, often with different adhesives in the different layers. The use of multiple adhesives is driven by the different requirements for each component of the construction.

The skin contact layer must adhere strongly to the skin for an extended period of time. Thus, it needs to combine cohesive strength (shear resistance) and adhesive strength to a constantly changing, highly variable, and low-surface-energy substrate (human skin), as well as resistance to deformation, sweat, moisture, and abrasion from clothing and other items. This adhesive must also exhibit strong bonding to the interlayer, which can include a range of breathable polyurethane films and nonwoven (NW) fabrics. Additional adhesive layers are critical to bonding the film or nonwoven either to additional films or the actual medical device.

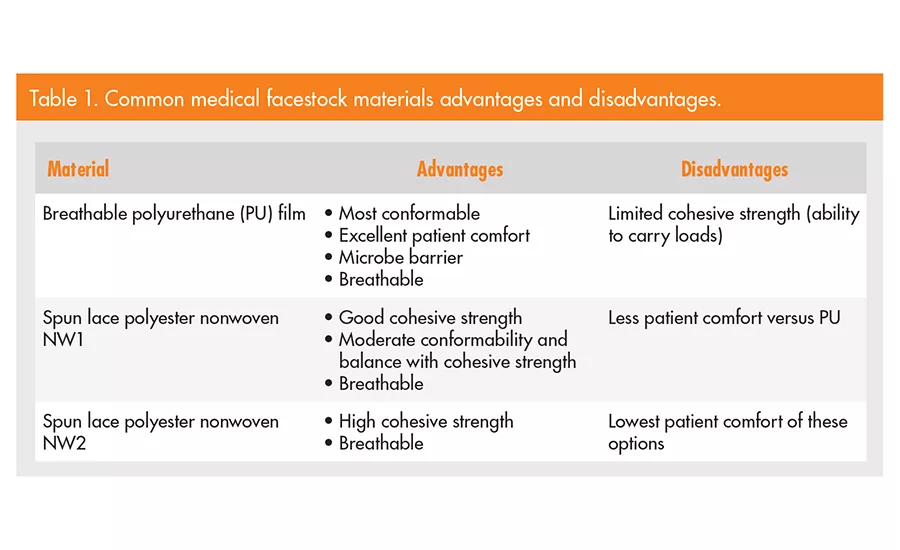

With the wide range of materials and constructions, a simplified laminate was used for evaluation to help medical application designers choose appropriate adhesive constructions for their specific demanding application. The simplified construction is a 1 x 3-in. test strip with an adhesive on specific facestock materials. For this work, three common medical facestock materials were included: a 1.2-mil breathable polyurethane film and two spun lace polyester nonwovens with densities of 1.3 oz/yd2 (NW1) and 2.4 oz/yd2 (NW2). The advantages and disadvantages of each material are shown in Table 1. From an adhesive selection perspective, understanding the interaction of the adhesive to specific industry-standard materials is critical to enabling the ability of medical applications engineers and designers to develop robust long-wear constructions.

Quantifying Wear

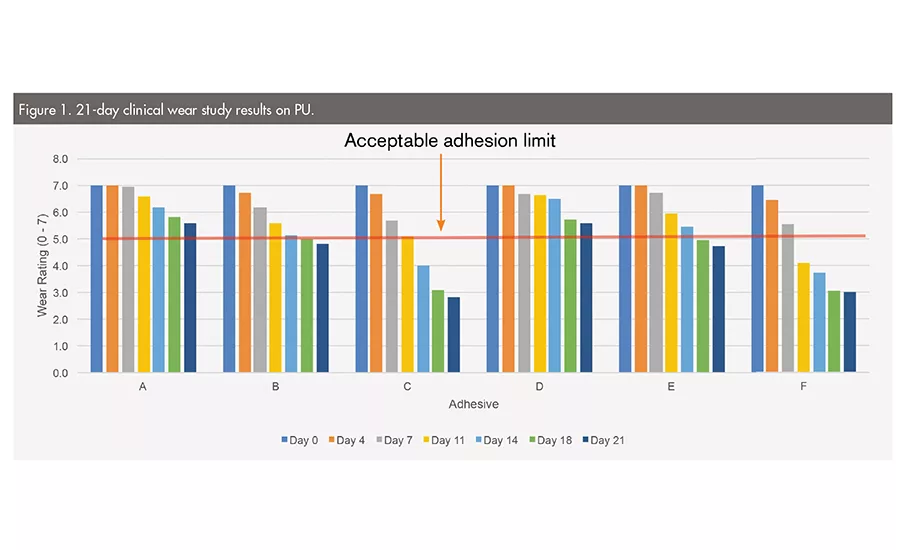

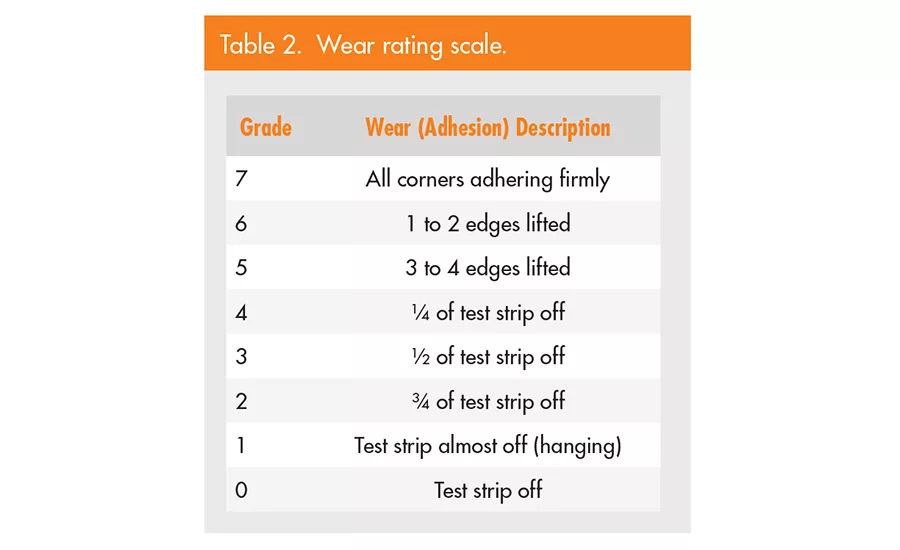

In order to optimize the choice of adhesive, a robust approach for quantifying long wear is critical. Clinical trials with a sufficient study population size were used in conjunction with a grading system for quantifying adhesion levels. Test strips with different adhesives and of different constructions were applied to individuals at Day 0, and then reviewed at Days 4, 7, 11, 14, 17 and 21. The grading scale is shown in Table 2.

Adhesives with a variety of properties were chosen for this study (see Table 3), covering a range of peel (adhesive strength), shear (cohesive strength), and moisture vapor transmission rate (MVTR) (breathability) values, as well as spanning a range of acrylic-related chemistries. From a performance perspective, a long-wear adhesive requires breathability at a minimum level. This is necessary to both avoid maceration, which is a patient comfort and skin quality problem, as well as to maintain acceptable adhesive-skin bonding. Moist skin is inherently very difficult to adhere to, and an occlusive (air and moisture barrier) construction will limit wear time.

For a medical applications engineer, a breathable polyurethane (PU) film provides the highest latitude for design options for long-wear applications. Adhesives A, B, D and E exhibited excellent wear on PU film for the 2+ week timeframe, as shown in Table 4 and Figure 1. Correlating the adhesive properties to the observed wear performance, the key learnings were:

- Medium- to high-peel products have excellent long-term wear potential

- A range of acrylic-related chemistries will perform well

- Shear (cohesive strength) is not a limiting factor, as several low- and high-shear products performed well

- A range of MVTR values all performed well

These results highlight why, although PU films are not the lowest-cost films, they have a strong presence in the medical market. The PU film provides optimal conditions for long wear due to:

- Low shear stresses on the adhesive due to excellent facestock conformability

- High surface energy provides optimal conditions for adhesive-facestock bonding

- Excellent breathability, allowing moisture to escape (preventing maceration and ensuring an appropriate skin surface for adhesive bonding)

After conducting wear studies with the two nonwoven materials, it is clear that their long-wear potential is significantly more limited than for PU films. For NW constructions, studying the wear characteristics at 1 week is more informative as to the required adhesive characteristics needed.

Table 5 highlights the wear characteristics at 1 and 3 weeks for the same set of adhesives on NW1 and NW2. From an adhesive perspective, the key learnings were quite similar to those from the PU studies:

- Medium to high peel performance is required for better wear

- A range of acrylic-related chemistries will perform well

- A range of MVTR values all performed well

In addition, specific to the NW constructions, the importance of cohesive strength was highlighted. Any range of shear values is acceptable for 1 week of wear; however, high shear coupled with high peel is required for wear times longer than 1 week. Higher cohesive strength is needed to resist the deformation forces of the more rigid NW facestocks.

Conclusion

Identifying the right skin-contact adhesive for long-wear applications can be challenging from a design perspective. For these applications, higher peel strength (higher adhesion) products are preferred, though a medium or lower peel product can be made to work under specific circumstances.

The standard types of acrylic chemistries all show potential for excellent long wear on human skin. As the conformability of the facestock decreases, higher shear strength coupled with medium to high peel is required. For suitable long wear, a minimum breathability is required, but higher breathability does not correlate with longer wear.

For more information, visit www.henkel.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!