Vertellus Showcases Advanced Adhesives, Sealants, and Gels at K 2019

According to Vertellus, its adhesives, sealants, and gels are helping a variety of device manufacturers maintain product integrity in the face of increasingly harsh environments.

At the recent K 2019 event, Vertellus showcased its portfolio of adhesives and sealants, which include its Polycin™ polyols, Vorite™ prepolymers, and Sealrite™ gels. According to the company, these materials are helping a variety of device manufacturers maintain product integrity in the face of increasingly harsh environments.

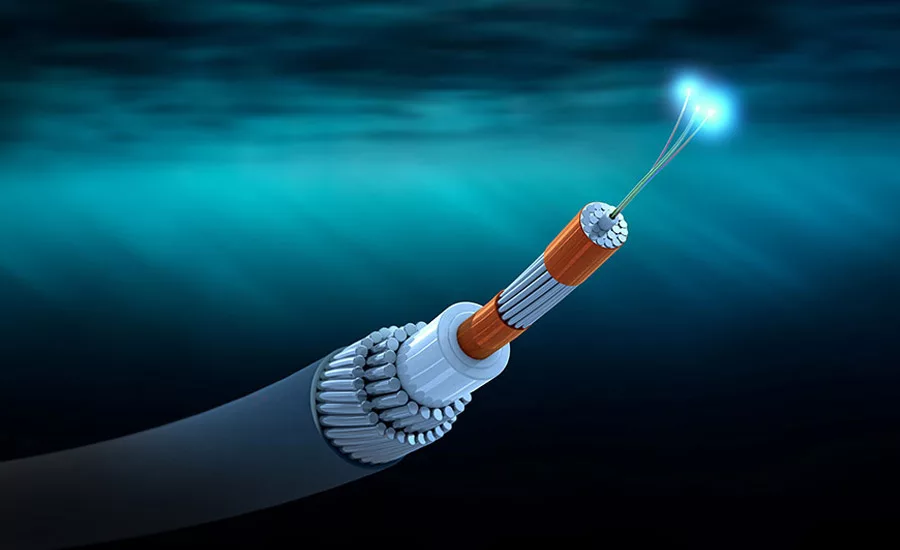

In the telecommunications industry, for example, the trend of increased data consumption in both consumer and industrial applications is driving the need for an increase in data transmission bandwidth. One result is the growth of the expanding deep-sea network of fiber optic data transmission lines. This tough environment places significant demands on the cable design, the components of which must be protected from extremely cold temperatures over the life of the cable.

To meet these needs, Vertellus reports that it offers D-Encapsulant, a two-component polyurethane (PU) system that features a low viscosity and extended pot life to form an effective water block, excellent flexibility, and electrical and long-term stability properties. Vertellus’ two-component PU systems, such as its D-Encapsulant, help enable the successful manufacture of sub-marine cables. These PU systems are hydrophobic, which keeps moisture from penetrating the sensitive electrical and fiber optic system. D-Encapsulant maintains low stress under a wide temperature range, which ensures no change in physical properties between -50 and 100˚C and is vital to the longevity of the cable assembly in deep-sea use.

As global electricity demand grows due to industrialization and electrification of rural areas, energy transmission systems need to be durable in increasingly harsher climate conditions. For the design of electrical and cable components that must withstand a wide range of temperature and humidity levels, Vertellus reports that its Sealrite gels offer beneficial mechanical and sealant properties. A single Sealrite formulation reportedly maintains its mechanical properties over wide operating conditions, preventing manufacturers from having to proliferate SKUs in order to meet the needs of different geographic regions.

Beyond industrial applications, adhesives and sealants for medical devices require materials that are not only safe to use when in contact with human tissue, but can also withstand challenging environments associated with manufacturing (multiple high-temperature curing cycles) and sterilization without compromising strength or mechanical properties. According to Vertellus, its Polycin polyols and Vorite prepolymers, when combined, become high-performance adhesive and sealant systems. Material components are designed and paired for applications with critical performance specifications, such as specific hardness and gel time, for dialyzers, oxygenators, and catheters.

Additional details are available at www.vertellus.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!