Pine-Based Tackifiers Offer Sustainable Packaging Solutions

Bio-based tackifiers allow packaging adhesive formulators to meet their most difficult challenges with minimal impact on the environment.

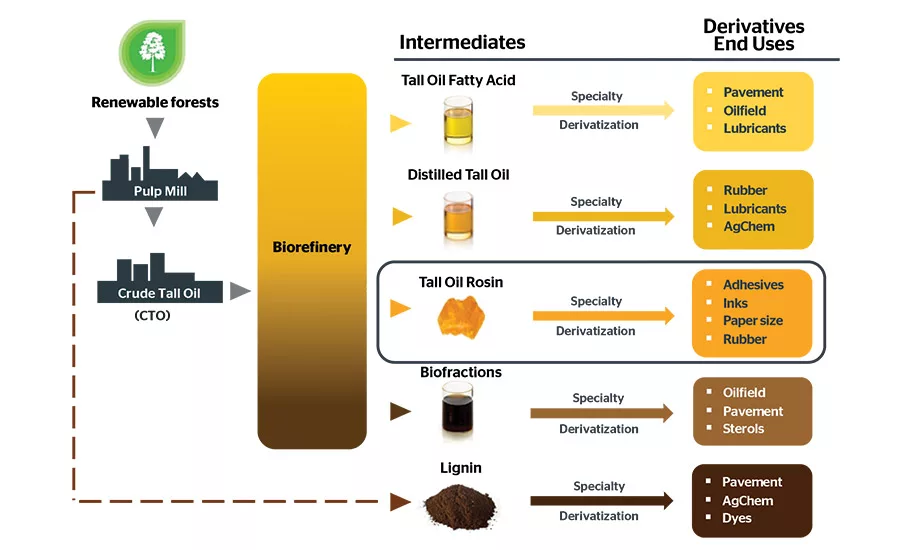

Figure 1. Pine chemical value chain.

Two of the biggest challenges facing the global adhesives and sealants market today are meeting consumer preferences for sustainable packaging and aligning with the industry’s increasing regulatory demands, especially when it comes to food applications. Contributing to 92% of retail packaging volume, or 3.4 trillion units, food and beverage packaging often becomes a focus of consumers and brand owners looking to improve their environmental footprint.1

In response to this growing trend toward eco-friendly packaging, adhesive and sealant suppliers can influence consumer goods companies to incorporate more packaging materials that are recyclable, compostable, or made from bio-renewable sources. To this end, adhesive formulators have the sizable task of finding products that have a sustainable profile without sacrificing performance, while raw material suppliers must overcome traditional beliefs about the efficacy of sustainable ingredients.

An Important Piece of the Packaging Puzzle

Adhesives are vital for packaging today and contribute to the sustainability of a package’s lifecycle. Although the adhesive typically makes up just 2% of an end-use package, optimal adhesion is necessary for high-performance packaging applications.

Since nearly half of an adhesive consists of a tackifier, adhesive suppliers can maximize their renewable content by incorporating a bio-based tackifier rather than a chemically derived alternative. If most of the package is also made from eco-friendly materials, using a bio-based tackifier will help the consumer come closer to fully sustainable packaging.

Historically, many adhesive chemistries are derived from petroleum or other chemical sources, including hydrocarbons. With a high manufacturing carbon footprint, the surplus use of these traditional tackifiers in adhesive formulations has the potential to negatively impact the environment. Bio-based tackifiers, such as those derived from rosin esters, provide better adhesion and improved overall performance.

In an effort to deliver tangible benefits such as better product performance, improved manufacturing operations, and reduced costs to adhesives producers, a portfolio of rosin ester tackifiers addresses the needs of diverse adhesive applications made almost exclusively from renewable resources. Products derived from crude tall oil, a co-product of the kraft sulphate pulping process (see Figure 1), allow for more consistent, higher quality rosin esters that are less labor intensive than alternative tackifiers derived from gum rosin. Tall oil rosin offers stability and quality advantages while being the most sustainable manufacturing process available.

As brand owners’ sustainability and cost goals continue to drive increased use of difficult-to-bond substrates with lasting and reliable performance, bio-based tackifiers allow adhesive formulators to meet their most difficult challenges with minimal impact on the environment. Rosin ester tackifiers combine differentiated adhesion with light color and advanced stability for stringent hot-melt adhesive requirements.*

Offering broad polymer compatibility, these products provide outstanding adhesion to difficult-to-bond surfaces. In addition, as a way for formulators and brand owners to improve their environmental footprint and address consumer demand for more sustainable offerings, a high-performance tackifier containing 99% bio-based content has been developed that meets performance requirements of traditional rosin ester tackifiers.**

*WestRez® and Altatac™

**Altatac ECO 100

Enhancing Product Performance and Lifecycle

Many factors drive formulators’ tackifier selection, including polymer compatibility, the type of substrate being used, and end-use requirements. Rosin esters have the broadest polymer compatibility of all tackifiers, meaning they provide formulation flexibility and are applicable across multiple adhesive systems. The polarity of a rosin ester can offer excellent adhesion to many difficult-to-bond substrates, while hydrocarbon alternatives are typically non-polar. Lastly, end-use requirements such as softening point, color, viscosity, and integrity are extremely important when choosing a tackifier.

Tall oil rosin esters provide consistent high-performance solutions for a broad array of adhesive applications. Not only can adhesive formulators choose the right tackifier for better performance, but they can also provide high-quality options for eco-conscious customers. Rosin ester-based tackifier performance attributes include:

- Bio-renewable resource (allows adhesive companies to provide sustainable options to end users)

- Low initial color (offers broader use of a sustainable tackifier in applications requiring a low color)

- Increased thermal stability (maintains quality during application)

- Superior adhesion to difficult-to-bond surfaces (e.g., recycled corrugated packaging)

Connecting Demand with Sustainable Solutions

As growing environmental concerns increasingly impact consumers’ purchasing decisions, many consumer goods companies have committed to improving the sustainability profile of their packaging. A world without packaging may not be realistic in all areas, but suppliers can support waste recovery efforts and greater circularity by making substrates more sustainable. Through the development of products based on renewable resources, adhesive and sealant companies can play their part in offering innovative and sustainable solutions to eco-conscious customers.

For additional information, visit www.ingevity.com/markets/adhesives.

Reference

- Legl, Carina, “The Power Of Sustainable Packaging,” Forbes, July 2019, www.forbes.com/sites/sap/2019/07/10/the-power-of-sustainable-packaging/#16536635be89.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!