Silicone Adhesives for Lifetime Performance in Vehicle Electrification and Autonomy

Module joint design, adhesive selection, substrate choice, and combined mechanical and environmental stresses in the field all impact the longevity of the protective seal on a vehicle's electronic part.

Transportation electronics in both battery electric vehicles (BEVs) and autonomous vehicles regulate crucial on-board domains such as drive control units, safety systems, proximity sensors, and connectivity controllers. The electronics in these increasingly sophisticated computers are susceptible to corrosion failures from exposure to water and salt during vehicle operation that can result in performance problems, loss of function, and expensive repairs.

To protect these electronics, suppliers of automotive electronics modules often use cure-in-place liquid adhesives or sealants. Suppliers, however, must differentiate among a variety of material types to select high-performance solutions to continuously protect crucial systems through many years of service life.

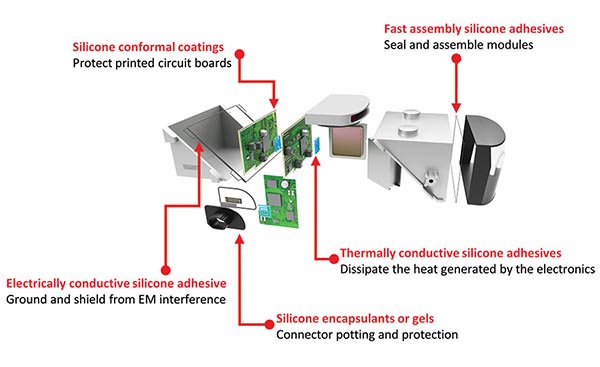

Figure 1. Transportation electronics are protected by a variety of silicone adhesive solutions.

Silicone Adhesives to Protect Transportation Electronics

Silicones consistently stand out as a material class of choice to ensure lifelong protection from environmental stresses due to their inherent chemical stability and stress-reducing mechanical flexibility (see Figure 1). At their core, silicones have a chemical backbone of silicon-oxygen bonds similar to glass that makes them inherently durable against harsh environmental stress, including temperature extremes and cycling, UV exposure, cyclic changes in humidity, and water immersion.

Silicone solutions also remain elastic and flexible under even these challenging conditions, relieving interfacial stresses in adhesive joints and allowing for small joint movements that prevent joint fatigue through years or even decades of service life of the electronic part. In addition, silicone adhesives are formulated to remove heat from circuit boards through the incorporation of thermally conductive additives. The inclusion of electrically conductive additives provides grounding and electromagnetic shielding to crucial systems without sacrificing short- or long-term adhesive properties.

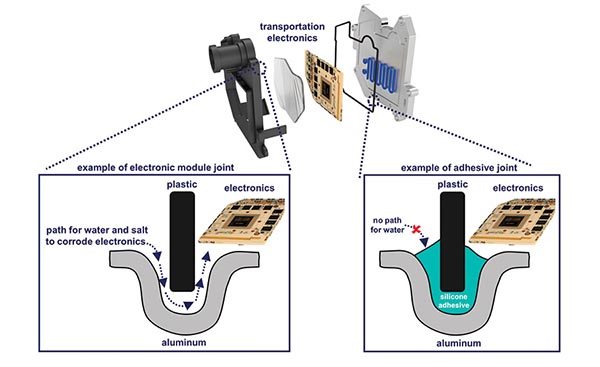

Advanced electronic control modules generally use aluminum alloys and engineered resins for their housings and connector components. These disparate substrates must be sealed together to prevent moisture ingress and protect the electronic components. The adhesive joints must be sufficiently durable to withstand repeated mechanical and environmental stresses. Figure 2 shows an example of an electronics adhesive joint filled with a flexible silicone adhesive that eliminates any path for water intrusion.

Figure 2. Example of silicone adhesive in transportation electronics module joint.

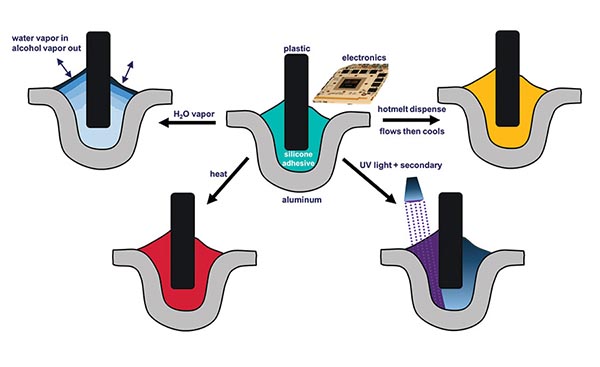

Silicone Adhesive Cure Chemistries to Match Production Needs

Silicone adhesives and sealants are formulated with a range of curing mechanisms to match manufacturing, supply chain, and performance needs (see Figure 3). Room-temperature-cure (RTV) adhesives, for example, cure with exposure to water vapor in air. Cure occurs as water vapor diffuses into the material and alcohol vapor leaves the material, following the condensation reaction of alkoxy moieties with water. This type of cure results in excellent adhesion to metals, metal alloys, glasses, and ceramics, as well as many plastics.

Figure 3. Silicone adhesive cure mechanisms.

No additional curing equipment is required for RTV adhesives; thus, they provide an excellent sustainability footprint based on low energy use. Cure times commonly on the order of days can present a logistical challenge in some supply chains if parts need to be tested, handled, or shipped immediately following assembly or before the silicone adhesive has sufficiently cured. Accordingly, an innovative trend by adhesive developers is to reduce cure times from hours or days to just minutes.

Another well-established silicone cure chemistry in the automotive industry is heat cure. Here, cure occurs in a large chamber oven or conveyor oven, typically requiring bondline temperature of 130-150°C. Cure proceeds through platinum-catalyzed hydrosilylation reactions. A typical heat-cure silicone adhesive requires 30-60 min of high-temperature exposure to cure and build adhesion strength to the various substrates. There are no byproducts or leaving groups from this reaction, and parts can be immediately tested, handled, and shipped after cooling.

Heat-cure adhesives adhere to a broader range of plastics than room-temperature-cure products due to the added energy during heating. However, the elevated temperatures required for cure can be limiting for some temperature-sensitive surfaces or electronic components in the module. As a result, innovative materials for this cure type are designed to cure faster to reduce time at high temperature and to build adhesion at lower temperatures (e.g., 80°C).

UV or photocure chemistry is gaining additional interest and focus as hybrid organosiloxane materials combine near-instant cure from photocurable groups with the inherent stability of silicones. This cure type is attractive due to a distinct “on-off” command from light exposure, low energy use, and fast speeds—requiring only seconds. A tradeoff is that cure only evolves in areas visible to light. To fully cure shadowed areas, a secondary cure is added whereby material exposed to UV light cures within seconds and shadow areas cure over longer times through the secondary cure mechanism.

A final cure type is a reactive silicone hot-melt adhesive, where the formulation is initially solid at room temperature. It is then heated to enable flow and is dispensed onto the part. The parts are assembled before the adhesive cools to yield instant adhesive force, commonly referred to as green strength. This dispense method requires a heated dispensing unit and careful operational workflow planning to ensure products are assembled in a timely manner after dispensing. This type of heating requires significantly less energy than that needed for heating an entire oven. The silicone adhesive builds additional adhesion strength with secondary cure over time through the previously mentioned RTV cure mechanism.

Adhesive Selection and Application-Specific Testing

Collaborating with a material supplier early in the development phase of an electronic module regarding adhesive selection can significantly improve success rates in validation trials and in final module performance. For example, small changes in the design of the bondline thickness of an adhesive joint can dramatically reduce the expected mechanical strain on the adhesive and joint, which will increase longevity.

In addition, certain adhesive cure chemistries are better-suited for durable adhesive performance on specific resin grades, which may not be obvious from product literature. While technical data sheets provide basic comparatives of material performance, reported values do not necessarily correlate to durable lifetime performance. Over-reliance on reported adhesion strength or lap shear strength values in data sheets, for example, may result in delayed validation cycles or even field failures if adhesion durability to the specific substrates is not correctly assessed.

Adhesion testing, then, should reflect the actual stresses experienced by the adhesive during the lifetime of the device, such as low but consistent or cyclical stresses and changes in environmental conditions. Specifically, adhesion durability tests (e.g., the wedge rupture test) that closely mimic real joint conditions are better predictors of lifetime performance vs. purely strength-based tests.1-4 Unlike strength-based lap shear or peel type tests in a lab, adhesion durability testing delivers information about a joint subjected to consistent but low mechanical stress, mimicking stresses that occur in the field. In combination with the consistent mechanical stress, samples are also exposed to environmental aging conditions such as thermal cycling, water submersion, and salt spray cycling.

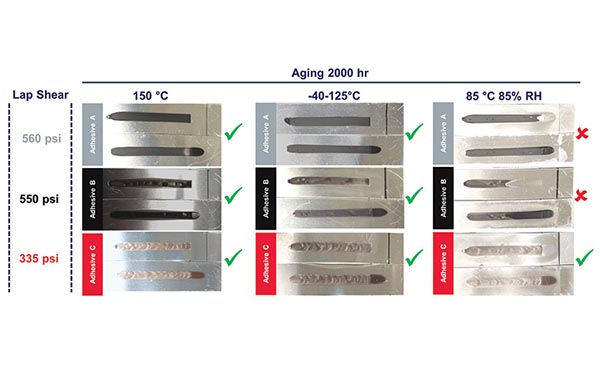

Figure 4 shows wedge durability samples that were opened following 2,000 hrs of aging at the provided environmental condition. Three silicone adhesives were compared. All three adhesives exhibit no failures in high heat (150°C) or thermal cycling testing

(-40-125°C), highlighting the excellent thermal stability of silicone adhesives. However, when exposed to the combined stresses of mechanical strain, high heat, and high humidity, Adhesives A and B both exhibit failures in as little as 250 hrs of environmental exposure. These adhesive failures could create a path for water ingress in modules, leading to electronics corrosion.

Figure 4. Accelerated aging of wedge test durability joints.

Adhesive C shows no failures after 2,000 hrs of aging under all conditions. It is important to note that the adhesion value to aluminum provided in a technical data sheet is lowest for Adhesive C vs. the other adhesives.

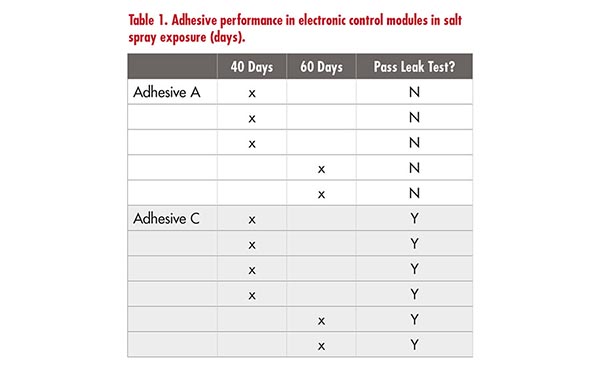

To illustrate the predictive capability of durability testing on actual performance in application, Adhesives A and C were used to seal fully assembled electronics control modules that were then subjected to 40 and 60 days of an automotive salt spray following an aggressive OEM method. The modules required a seal between a stamped aluminum lid and a cast aluminum housing. The steps of the standard include:

- Mount component at intended final orientation

- Soak in chamber at 70°C for 1 hr

- Adjust to 35°C; spray with 5 wt% salt solution for 1 hr

- Turn off salt spray; allow chamber to cool to RT for 1 hr

- Repeat steps 2-3 three times for a total of 9 hrs

- 15 hrs at RT; humidity uncontrolled and no salt spray

- 24-hr sequence repeated for desired number of cycles

After being sealed, all modules assembled with both adhesives passed initial air pressure leak testing before being placed into the salt spray cycle. As seen in Table 1, all modules sealed with Adhesive A failed after 40- and 60-day salt spray testing, but all modules sealed with Adhesive C passed the aggressive testing.

The technical data sheet values for adhesion strength to aluminum for Adhesive A (560 psi) and Adhesive C (335 psi) did not predict in-application performance. However, as seen in Figure 4, evaluation of both adhesives using wedge durability samples aged in application-relevant conditions that included combined mechanical and environmental stresses strongly correlated to the adhesives’ performance in the final module.

Application-Specific Requirements

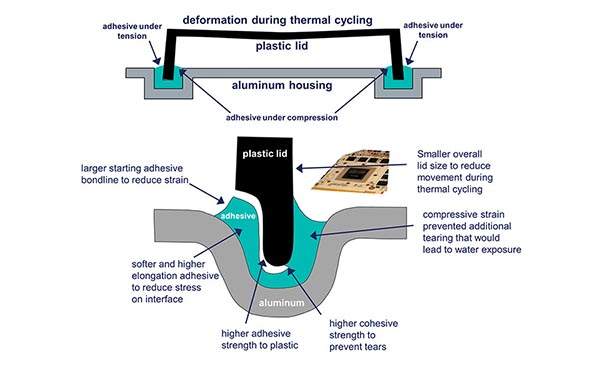

Along with selecting an appropriate cure chemistry and conducting application-relevant durability tests, working with a material supplier that understands the application requirements is a critical step toward quickly achieving a reliable adhesive solution and assembly. For example, an adhesive joint in a customer’s electronic module was experiencing failure that was visually observed following thermal cycling. The adhesive was delaminating from the plastic lid and partially tearing during aging.

Figure 5 provides a simplified schematic of the joint and cause of stress. During thermal cycling, the expansion and contraction of the plastic lid results in tension and compression forces on the adhesive that lead to both adhesive failure from the plastic and some cohesive failure or tearing of the adhesive. Technical recommendations to address the problem included:

- Increase gap for the starting bondline to reduce joint strain

- Use a softer and higher elongation adhesive to reduce interfacial stress at the plastic lid

- Increase adhesion strength to the specific grade of plastic used for the lid

- Increase cohesive strength of the adhesive to prevent cohesive tears under stresses

- Use a smaller lid size to reduce total stretching or strain on the joint to improve stability

Module joint design, adhesive selection, substrate choice, and combined mechanical and environmental stresses in the field all impact the longevity of the protective seal on an electronic part. The rate of success to produce modules that last for the expected lifetime of the vehicle dramatically improves when selecting inherently durable materials, matching the cure chemistry to the right substrates, and focusing on application-specific performance targets rather than simple technical data sheet values.

Figure 5. Forces acting on adhesive joint and example technical solutions to address failure.

Partnering for Success

The mobility and transportation industry is undergoing dramatic shifts as BEV and autonomous driving technology advance. Partnering with an adhesive manufacturer helps define adhesive material requirements that enable innovations to meet challenging lifetime performance requirements in these applications.

For more information, contact the author at (989) 496-8213 or bradley.tuft@dow.com, or visit www.dow.com.

References

- D. Dillard, B. Duncan, Advances in Structural Adhesive Bonding, 2010, pp. 389-436.

- A. Baker, J. Wang, Aircraft Sustainment and Repair, 2018, pp. 191-252.

- ISO 10354, www.iso.org/obp/ui/#iso:std:iso:10354:ed-1:v1:en.

- ASTM D 3762, www.astm.org/Standards/D3762.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!