Eliminating Adhesive Buildup with Air-Operated Double-Diaphragm Pumps

Next-generation diaphragms have been designed to meet the pumping challenges inherent in the sticky and viscous materials that are the foundation of adhesive and coating manufacturing.

It’s simple: without adhesives, the world would literally fall apart. They are utilized in almost every industry in the world and in the manufacture of millions of unique products, with the highest concentration in the packaging, automotive, electronics, building and construction, home goods, textiles, and transportation markets.

A key component in the adhesive production chain is the pumps that are used to transfer raw materials and finished products. The adhesive manufacturing process typically involves a roster of solvents, catalysts, and resins combined together in order to create the finished adhesive product.

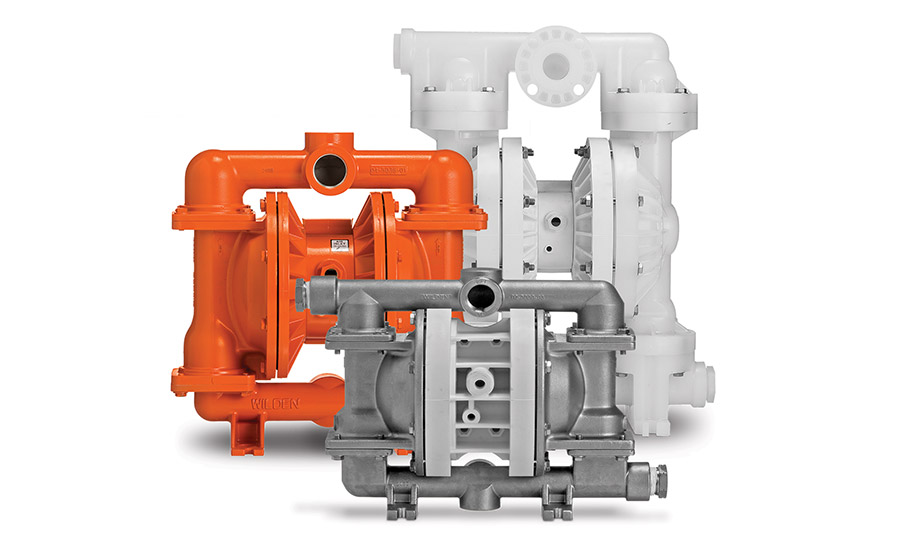

As a result, the pumps that are used to facilitate the adhesive production process must be versatile, reliable, and robust enough to handle liquids of many different types and structures, including those that may be corrosive, abrasive, or hazardous. Positive displacement air-operated double-diaphragm (AODD) pumps—especially those that are outfitted with next-generation diaphragm technologies—possess the operational and compatibility capabilities for use in the manufacture of the adhesives that help keep the world in one piece.

The Challenge

One of the main challenges in manufacturing adhesives—whether the process is water based, solvent based or hot melt—is the fact that they are sticky, viscous liquids. In other words, the “adhesiveness” of adhesives can make them particularly difficult to produce.

This can be a truly visceral challenge for operators and maintenance teams, as chemical adhesives (along with some technically non-adhesive products such as latex coatings) often form a buildup, known as “skins,” on the pump’s internal passages and components. This buildup is particularly common on the outer piston of traditional diaphragm designs, which require an inner and outer piston to hold the diaphragm in place. The outer piston inherently has added surface area and space for buildup to occur.

This buildup can cause problems in several ways:

- Slough off into the product stream, where the bits of hardened adhesive clog filters, pipes, etc.

- Slough off and get stuck in the pump itself, which will minimally reduce overall performance and potentially cause the pump to stall; smaller internal clearances related to the buildup can lead to premature wear

- Remain attached to the outer piston, with the growing buildup damaging the pump’s liquid chamber

These buildup issues result in increased maintenance, cleaning, and repair of wear components. In AODD pumps, this means the balls, seats, and diaphragms that are integral to the pumping process are affected. In addition, increased downtime can result when the pump needs to be taken offline for cleaning and maintenance. This makes meeting strict production schedules much more difficult.

Operators and maintenance teams often take the brunt of the true challenge when removing adhesive buildup from process equipment and pumps. In many cases, the only way to remove the buildup is with the use of a hammer and chisel. In facilities where the use of hazardous materials means the operation must be entirely explosion proof, no power tools can be used. As a result, the hammer-and-chisel method is often the only method available for adhesive buildup removal.

This is not only personally frustrating for whoever is charged with removing the buildup. In the worst-case scenario, the only possible outcome may be to simply replace the old pump with a new one, which can harm the operation from a financial perspective.

The ultimate downside to adhesive manufacture, no matter the pump technology being used, is the fact that all of the operation-hampering scenarios that result from product buildup will eventually combine to result in pump failure. In addition to excessive replacement costs, product leakage can compromise operational safety, as well as the safety of site personnel, surrounding communities, and the environment.

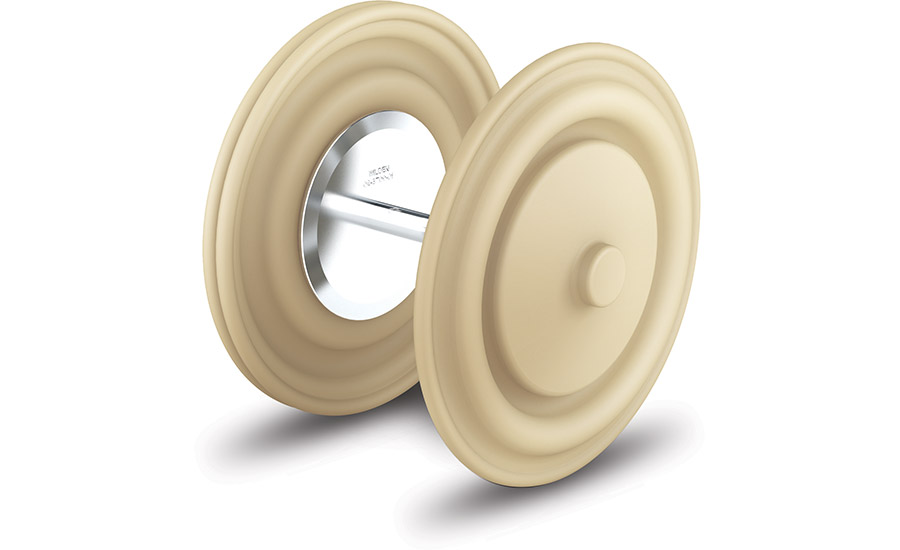

A new integral piston diaphragm (IPD) reduces the risk that damaging product buildup will occur in AODD pumps.

The Solution

A new diaphragm* has been designed to combat the deleterious effects that adhesive buildup can have on the operation and reliability of traditional two-piece AODD pump diaphragm designs. This diaphragm features a one-piece integral piston diaphragm (IPD) design that encases the outer piston within the diaphragm material**. The material, which reduces the potential for any product buildup to occur during normal operation, also benefits the operator through its excellent flex life, high chemical and abrasion resistance, and durability. These properties lead to longer service life, as well as lower maintenance and replacement costs.

In effect, the design of the new diaphragm takes the stickiness, high viscosity, and product buildup concerns that are common in the transfer of adhesives and makes them irrelevant. This also serves to make them easier to clean than traditional diaphragm models, therefore saving time and money by enhancing the speed of product changeovers. Finally, the IPD design eliminates a potential leak point around the outer piston and the failure-causing abrasion points at the outer piston, extending diaphragm life.

What further differentiates the new diaphragm from other IPD designs on the market is that it utilizes full-length shafts, which provide the same performance as the standard diaphragms. Other IPDs also require a shorter stroke, which gives them reduced flow and reduced suction-lift capabilities. This reduction is exacerbated when handling a highly viscous fluid, which makes it more difficult and time consuming to get the product into and then out of the pump.

The diaphragms’ construction material makes them 50% less expensive than PTFE-laminate models. They are compatible with many bolted metal and plastic pump models at operating temperatures ranging from -40 to 225ºF.

The use of next-generation IPDs can improve the performance, safety, and reliability of metal and plastic bolted AODD pumps.

Improved Processes

The world wouldn’t function properly without adhesives, and adhesives producers can’t function without the proper pumping technology. AODD pumps have proven to be a leading choice in adhesive manufacturing applications. Their capabilities are enhanced further through the benefits that the new diaphragms can offer, specifically as they relate to eliminating product internal buildup. While there is no guarantee that product buildup will be eliminated completely, the design of these IPDs greatly reduces the chance of potential buildup when compared to other IPD designs.

The lack of product buildup also eliminates a major headache for operators, who no longer need to worry that their AODD pumps will become fouled or that any part of the buildup may slough off into the product stream. The result is an upgraded AODD pump that is easier to use and maintain. This creates a safer, more efficient, and more reliable production process for some of the world’s most important products.

For more information, visit www.wildenpump.com.

*The Chem-Fuse Diaphragm

**Typically Wil-flex™, which is constructed of Santoprene®

Note: Images courtesy of Wilden.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!