Covestro to Present Multiple Technologies During Digital Expo

Applications of technologies featured at the expo include the bonding of upper material to the outsole of shoes and the application of adhesives to smartphone displays.

On September 14-16, Covestro will hold Digital Expo 2021 to highlight its technological offerings in four categories: Mobility, Living, Construction & Infrastructure, and Packaging. One example can be found in the manufacture of casual shoes, sneakers, and sports shoes. When bonding the upper material and the outsole, it is important to ensure exact dosing and precise application at the correct location so that the sole does not come off and visibly excessive application is avoided.

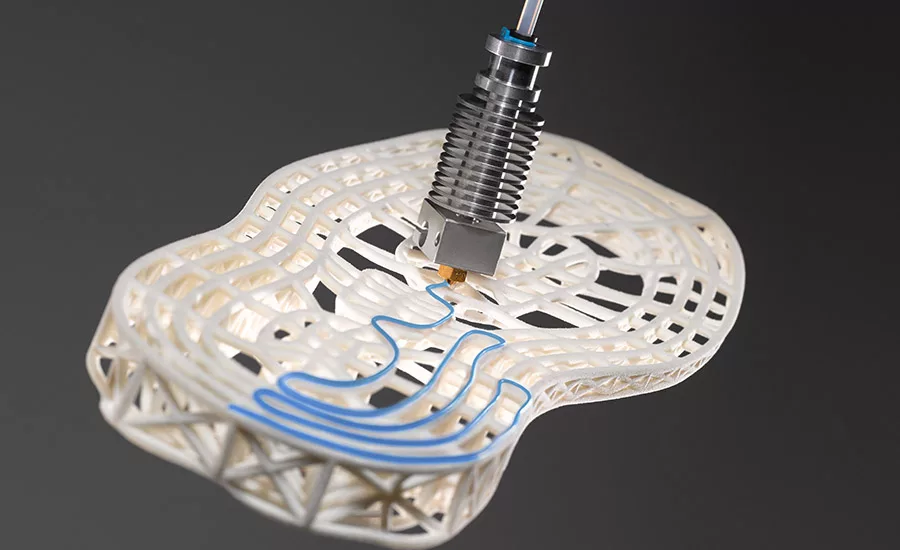

Many of the labor-intensive production steps in this process are still performed manually, however, such as the application of the adhesive with a brush. Covestro reports that hot-melt adhesives based on its Desmomelt® U thermoplastic raw material powder can be applied automatically and in precise doses using digital printing.

Polyurethane dispersions have proven their worth in adhesives for manual shoe production, but attempts to automate manual application with robot-assisted processes have not been successful to date. However, digital printing enables shoe manufacturers to automate adhesive application to the highest level of precision. This is significantly more effective and faster, as processing steps can be saved and the precise digital application creates less waste that would need to be disposed of. The adhesive joints exhibit the same high quality as with the previous manual production.

Similarly, the application of adhesives to smartphone displays is often a time-consuming part of the manufacturing process. For example, adhesive foils are applied that must be precisely cut beforehand. An analogous process is based on latently reactive two-component hot-melt films, which are still crosslinked after the joining process to create a particularly strong adhesive bond between the components. Due to the strong bond, however, disassembly at the end of the service life is often difficult.

According to Covestro, hot-melt adhesives based on Desmomelt U can be applied exactly where they are needed using digital printing, and the automation of the adhesive application process reduces the number of processing steps required. Nevertheless, complex, CAD-based adhesive bonding paths are possible. After usage of the smartphone, it is possible to disassemble components in a temperature-controlled manner if only thermoplastic raw materials have been used. If particularly strong adhesive bonds are required, the digital application of latent 2C reactive hot-melt adhesives based on Desmomelt U and Desmodur® crosslinkers is also possible.

To explore the Digital Expo, visit https://solutions.covestro.com/en/digital-event-space/ecs.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!