CONAGEN: Debondable Structural Adhesive

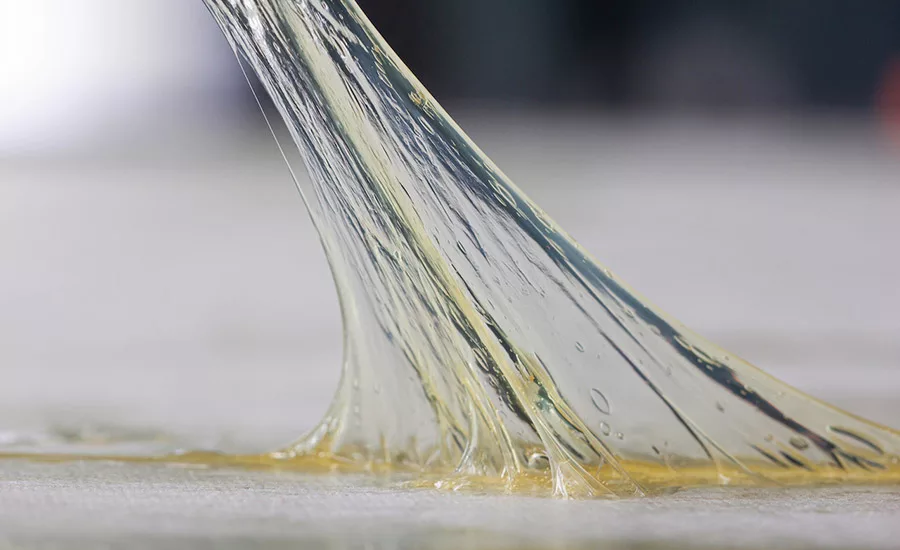

A crosslinked material designed with reversibility in mind, this adhesive exhibits the strength of traditionally cured adhesives with the added benefit of transitioning to a flowable material after heating. (Photo courtesy of Conagen.)

Conagen recently announced the development of debondable hot-melt adhesives made with high-performance materials from sustainable and natural biomolecules. According to the company, it leverages its precision fermentation technology to engineer a synthetic pathway independent of plant source materials, creating more efficient and sustainable bio-based ingredients than what can be achieved with chemically synthesized versions.

Most reactive hot-melt adhesives rely on post-curing chemistry to develop adhesive strength. A downside to this approach is that the curing process is irreversible and, as such, hinders or prevents debonding almost entirely.

“Conagen has solved the challenges manufacturers face in seeking strong structural adhesives that are long-lasting, perform strongly, but also have the option for breaking the adhesion before final finishing operations to deliver perfect products,” said J. McNamara, vice president of chemical applications. “Conagen’s patented debondable hot melt adhesive are incredibly stronger than what is used in the market now and can outperform petroleum-based products with a sustainable advantage that saves time, cost and reduces waste.”

Conagen reports that its adhesive is a crosslinked material designed with reversibility in mind. The product exhibits the strength of traditionally cured adhesives with the added benefit of transitioning to a flowable material after heating. The debondable adhesive formulation is ideal for cars, boats, planes, transportation, consumer electronics and appliances, and military and industrial applications.

“Our adhesive formulation continues to show promise for bonding a wide array of materials, such as metal, plastic, and glass,” McNamara said. “We’re making it easier for companies to adopt a more natural position in manufacturing while staying true to the long-lasting performance of their products.”

Learn more at www.conagen.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!