New Medical Adhesive Derived From Shellfish Has Potential to Advance New Solutions for Unmet Clinical Needs

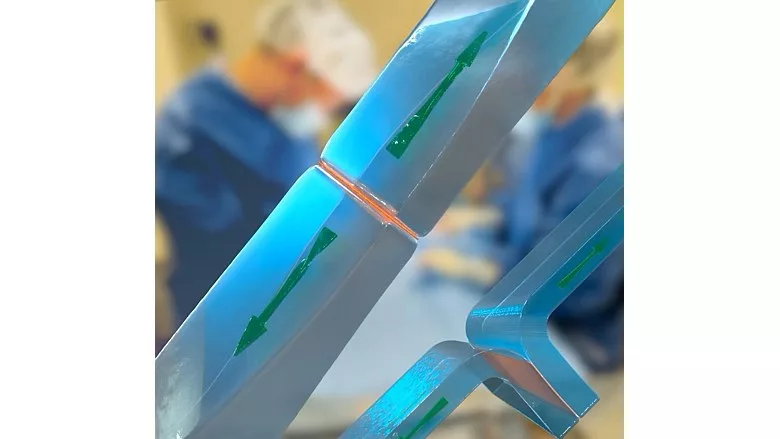

This illustration highlights how two hydrogels (shown in blue) can be bonded in different ways by thin chitosan films (shown in orange). The bonds that form are extraordinarily strong and can resist high tensions. Photo courtesy of Peter Allen, Ryan Allen, and James C. Weaver.

Harvard researchers have found that chitosan films, a fibrous, sugar-based material derived from the processed outer skeletons of shellfish, achieved rapid and strong bonding of hydrogels through chemical and physical interactions that are different from those involved in traditional hydrogel bonding methods.

Hydrogels are versatile biomaterials used in an increasing number of biomedical areas. Consisting of water-swollen molecular networks that can be tailored to mimic the mechanical and chemical features of various organs and tissues, they can interface within the body and on its outer surfaces without causing any damage to even the most delicate parts of the human anatomy. Hydrogels are already used in clinical practice for the therapeutic delivery of drugs to fight pathogens.

Attaching hydrogel polymers quickly and strongly to one another has remained an unresolved need as traditional methods often result in weaker adhesion after longer-than-desired adhesion times and rely on complex procedures. Achieving rapid adhesion of polymers could enable numerous new applications, including hydrogels whose stiffness could be finely tuned to better conform to specific tissues, on-demand encapsulation of flexible electronics for medical diagnostics, or the creation of self-adhesive tissue wraps for hard-to-bandage parts of the body.

Scientists at the Wyss Institute for Biologically Inspired Engineering at Harvard University and Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) have created a simple and versatile method to instantly and effectively bond layers made of the same or different types of hydrogels and other polymeric materials, using a thin film of the bio-based material chitosan. They successfully applied their new approach to several unsolved medical problems, including the local protective cooling of tissues, sealing of vascular injuries, and prevention of unwanted “surgical adhesions” of internal body surfaces that should not stick to each other. The findings are published in the Proceedings of the National Academy of Science (PNAS).

The team found that chitosan films achieved rapid and strong bonding of hydrogels through chemical and physical interactions that are different from those involved in traditional hydrogel bonding methods. Instead of creating new chemical bonds based on the sharing of electrons between individual atoms (covalent bonds), induced by a tiny shift in pH, chitosan’s sugar strands rapidly absorb water residing between hydrogel layers and entangle themselves with the polymer stands of hydrogels, forming multiple bonds via electrostatic interactions and hydrogen bonding (non-covalent bonds). This results in adhesive forces between hydrogels that significantly exceed those created through traditional hydrogel bonding approaches.

“Chitosan films with their abilities to effectively assemble, fine-tune, and protect hydrogels in the body and beyond, open numerous new opportunities to create devices for regenerative medicine and surgical care,” said senior author and Founding Wyss Institute Core Faculty member David Mooney, Ph.D. “The speed, ease, and effectiveness with which they can be applied makes them highly versatile tools and components for in vivo assembly processes in often short time-windows during surgeries, and the simple fabrication of complex biomaterial structures in manufacturing facilities.”

“The numerous possibilities emerging from this study by Dave Mooney’s group add a new dimension to the engineering of biomedical hydrogel devices, which could lead to elegant solutions for urgent unmet problems in regenerative and surgical medicine that many patients could benefit from,” said Wyss Founding Director Donald Ingber, M.D., Ph.D.

Additional authors on the study are co-first author Juan Cintron Cruz, Mathew Lee, and James Weaver at the Wyss Institute and SEAS; Phoebe Kwon, Haley Jeffers, and Daniel Kent at SEAS; and Kyle Wu at Beth Israel Deaconess Medical Center in Boston. The study was supported by the Wyss Institute at Harvard University, the National Institutes of Health’s National Institute on Aging, and the Harvard GSAS Research Scholar initiative.

To learn more, visit www.wyss.harvard.edu/news.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!