Three Key Trends Shaping Adhesives and Sealants Advances

The importance of adhesives and sealants may be sometimes overlooked, but trends within these product classes matter.

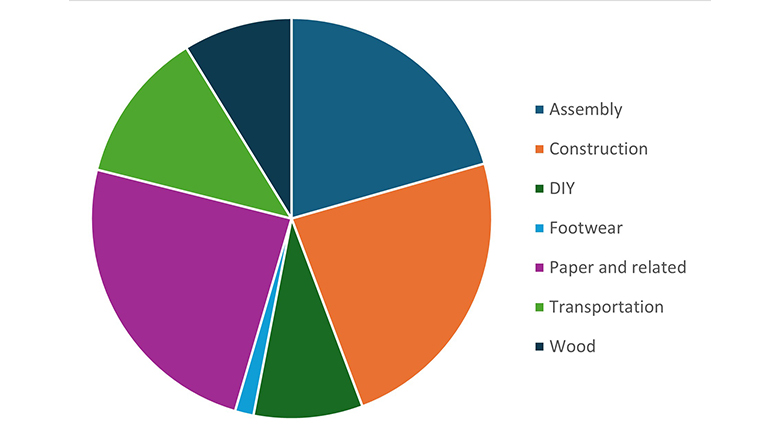

Adhesives and sealants guarantee efficiency, performance, and durability in myriad products and processes across multiple industry sectors, from the assembly of our cars and the construction of our houses to the packaging of the food we eat and the assembly of the mobile electronic devices that rule our daily lives (see Figure 1). The importance of adhesives and sealants may be sometimes overlooked, but trends within these product classes matter, because they dictate innovation, compliance, and competitiveness across numerous key industries.

Sustainability and low‑emission chemistries drive reformulation to meet volatile organic compound (VOC) rules, as well as environmental, social, and governance (ESG) targets, ensuring products remain specified in packaging, construction, and automotive. Lightweighting and multi‑material bonding enable electrical vehicles (EVs), aerospace, and other methods of transport to replace mechanical fasteners, reduce weight, and join dissimilar substrates, making adhesives central to design strategies. Automation, faster curing, and digital process control support high‑speed packaging, electronics, and robotic assembly, reducing waste and labour costs. Together, these trends shape R&D priorities, procurement criteria, and market access, determining which suppliers remain qualified.

Sustainability and Low‑Emission Chemistries

Sustainability and low‑emission chemistries are central because they sit at the intersection of regulation, customer demand, and competitiveness. Stricter VOC and isocyanate limits in the EU, United States, and China are forcing reformulation, with noncompliant products at risk of exclusion from supply chains.

OEMs and brand owners are embedding sustainability key performance indicators (KPIs) into contracts, making adhesives a focal point since they can either enable or hinder recyclability and emissions goals. Low‑emission, biobased, or recyclable formulations are now differentiators that help customers achieve certifications such as LEED or BREEAM and meet net‑zero commitments.

This trend is already reshaping the market. Sika has introduced SikaSeal®‑106 Construction, a water‑based sealant with EC1plus low‑emission classification, designed to replace solventborne silicones while still performing on substrates like gypsum and foams. Swiss adhesive manufacturer ATP Adhesives will invest $70 million in a facility in South Carolina to manufacture solvent‑free tape. And Henkel and Synthomer have linked renewable energy sourcing directly to adhesive products, enabling measurable carbon footprint reductions per SKU that procurement teams can document.

According to Germany’s Industrial Adhesives Association (IVK), adhesive technology is becoming a crucial driver of sustainable product design and resource‑efficient value chains in Europe. Adhesives play a key role in the R‑strategies (rethink, reduce, reuse, repair, refurbish, remanufacture, recycle…) of the circular economy. Sustainability is about regulatory survival, customer compliance, and enabling downstream industries to meet ESG goals. The companies that succeed will be those that are able to document emissions reductions, prove recyclability compatibility, and maintain performance parity with legacy systems.

Lightweighting and Multi‑Material Bonding

The concepts of lightweighting and multi‑material bonding are pivotal because they support the transformation of transportation, construction, and electronics toward greater efficiency and sustainability. Traditional fasteners and welds add weight, limit design flexibility, and struggle with joining dissimilar substrates. Adhesives, by contrast, enable strong, durable, and flexible bonds between metals, composites, plastics, and glass, making them essential for modern engineering.

Within automotive, adhesives are replacing rivets and welds in EV battery packs and bonding aluminum to composites to reduce mass, all while maintaining crash resistance and ensuring good thermal management. Bostik is actively developing tailored adhesives to support the transition within the EV market from “cell‑to‑module” technology to the “cell‑to‑pack/chassis” concept. In addition, European OEMs such as Airbus (in the A350 series) and BMW (in the i3 and i8 range) rely on epoxy‑based structural adhesives to join carbon‑fiber composites with metals, cutting weight and improving fuel economy.

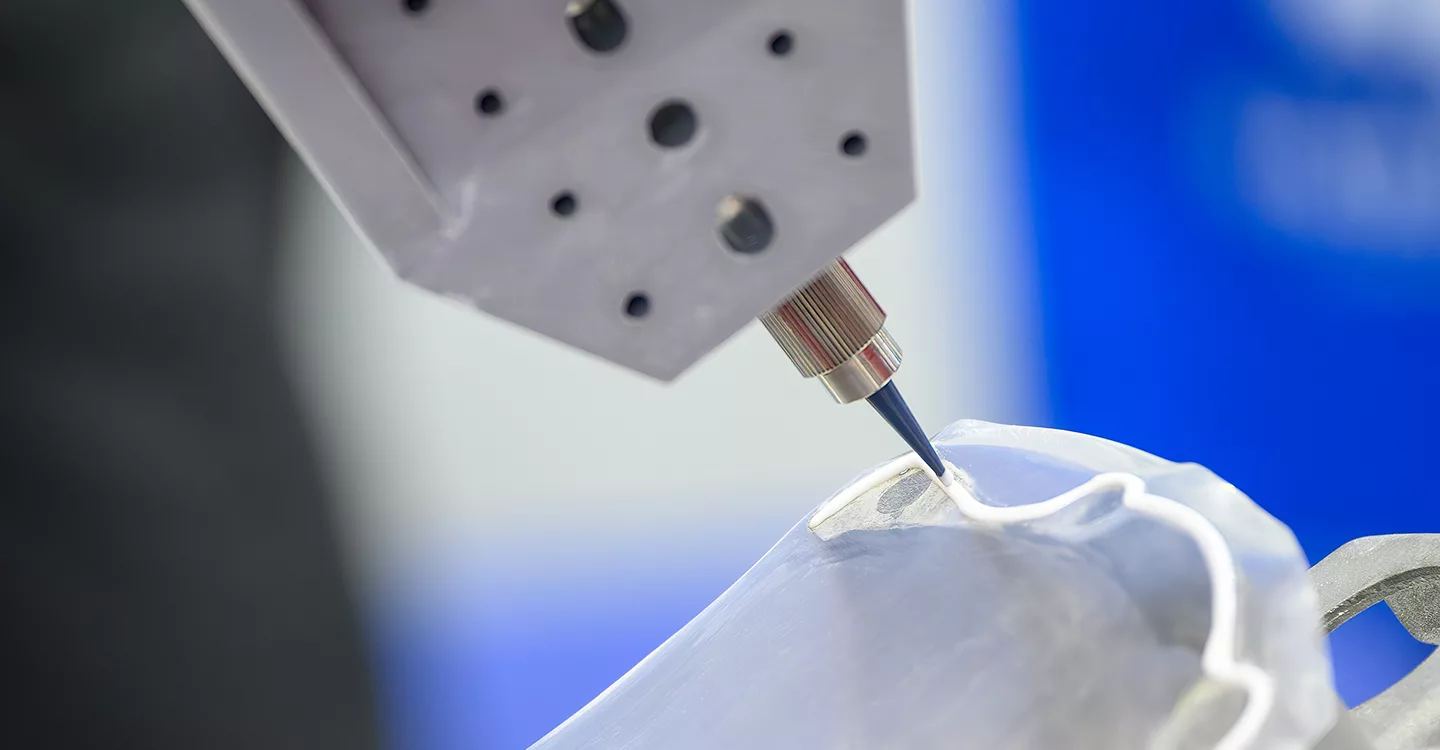

Within electronics, smartphones and wearables use adhesives to bond glass, plastics, and metals in slim, lightweight designs while also providing shock absorption and the management of heat dissipation and electrical insulation (or conductivity). DELO's Dualbond EG4797 solvent‑free acrylate enables ultra‑fine structures with line widths under 100 µm, allowing rapid‑curing, high‑precision bonding in optical and semiconductor packaging.

Automation, Faster Curing, and Digital Process Control

Automation, faster curing, and digital process control are aimed at improving throughput, consistency, and cost efficiency in high‑volume manufacturing. Adhesives can be applied at scale in automotive, electronics, packaging, and construction, where manual processes create variability and waste. Robotics, advanced curing chemistries, and digital monitoring deliver higher precision, lower labor costs, and faster cycle times while ensuring quality and compliance.

Henkel’s LOCTITE® robotic dispensing systems apply adhesives with repeatable accuracy, reducing waste in electronics and automotive assembly. L&L Products’ heat‑activated sealants and structural adhesives, applied via the company’s XIP® process, integrate seamlessly into automotive stamping and painting lines. In packaging, UV‑curable hot‑melt adhesives enable high‑speed carton sealing and labelling with cure times measured in seconds.

These advances show that automation and digital control are not just efficiency tools but enablers of new chemistries and application methods. They allow adhesives to keep pace with modern manufacturing, offering high‑speed, multi‑material bonding, as well as zero‑defect quality with scalability and repeatability.

Interconnected Forces

Taken together, these three dominant trends are redefining the adhesives and sealants segment. They are not isolated shifts but interconnected forces that determine which products win specifications, which suppliers remain qualified, and how value chains adapt to regulatory, technical, and operational pressures.

Adhesives are no longer background consumables; they are strategic enablers of greener supply chains, lighter designs, and smarter high‑speed manufacturing. Their relevance today — and in the future — lies in shaping both compliance and competitive advantage.

For additional information, reach out to pmarsh@chemquest.com or visit https://chemquest.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!